Limiting and stabilizing structure of drawer sliding rail

A technology for stabilizing structures and drawers, applied in drawers, furniture parts, household appliances, etc., can solve problems that affect the service life of drawers, the gear shaft is easy to be bent, and the guide rail movement is not smooth, etc., to achieve a simple and reasonable structure, pull Smooth, reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

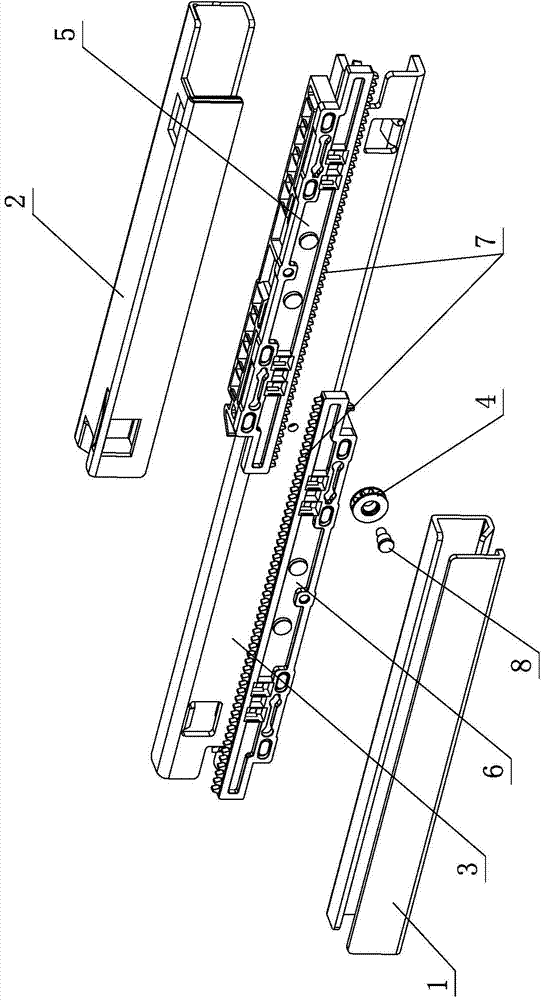

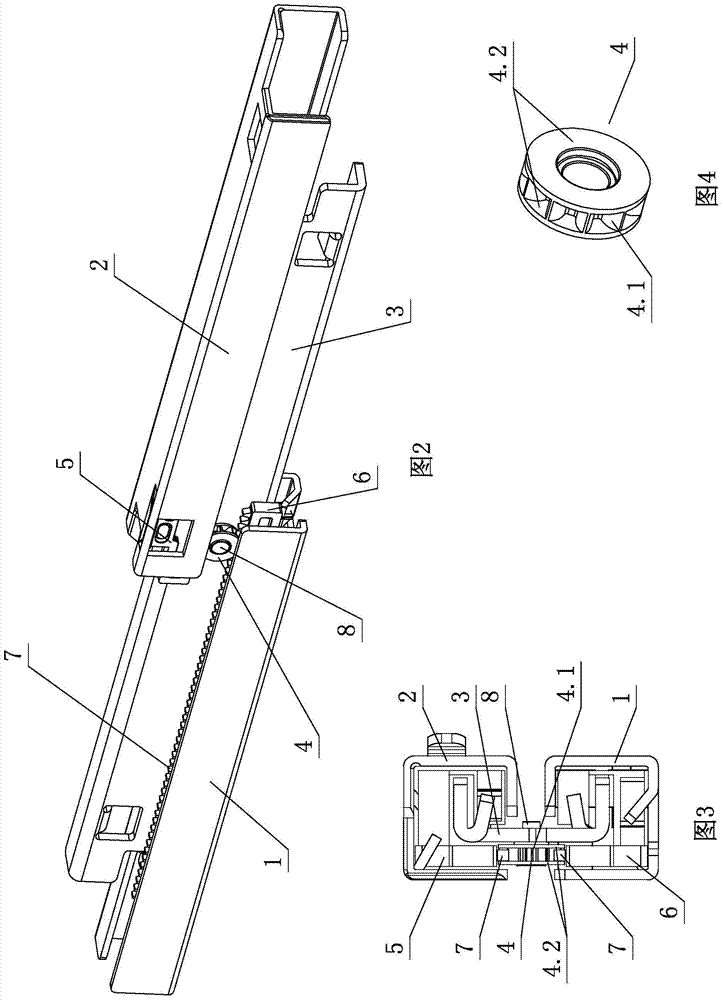

[0041] see Figure 1-Figure 4 , the position-limiting and stable structure of the drawer slide rail includes a fixed rail 1 arranged on the main body of the furniture, a movable rail 2 arranged on the furniture drawer, and an intermediate rail arranged between the fixed rail 1 and the movable rail 2. rail 3, the three rails are slidingly connected to each other through the synchronous wheel 4, the synchronous wheel 4 is made of plastic, and is rotatably arranged on the middle rail 3, and slidingly arranged between the fixed rail 1, the movable rail 2 and the middle rail 3 In the sliding bracket assembly, the synchronous wheel 4 acts on the fixed rail 1, the movable rail 2, and / or the sliding bracket assembly; the synchronous wheel 4 is a gear plate structure with the functions of both limiting and increasing strength.

[0042] Specifically, the sliding bracket assembly includes a first sliding bracket 5 and a second sliding bracket 6 respectively arranged between the movable r...

no. 2 example

[0049] see Figure 5-Figure 7 , the position-limiting and stable structure of the drawer slide rail is different from the first embodiment in that: the right side of the gear part 4.1 is provided with a position-limiting reinforced part 4.2 which has both position-limiting and strength-increasing functions, and the right side of the synchronous wheel 4 The side passes through the gear part 4.1 to cooperate with the limit reinforcement part 4.2 to form a right closed disc shape.

[0050] Others are not described in the first embodiment.

no. 3 example

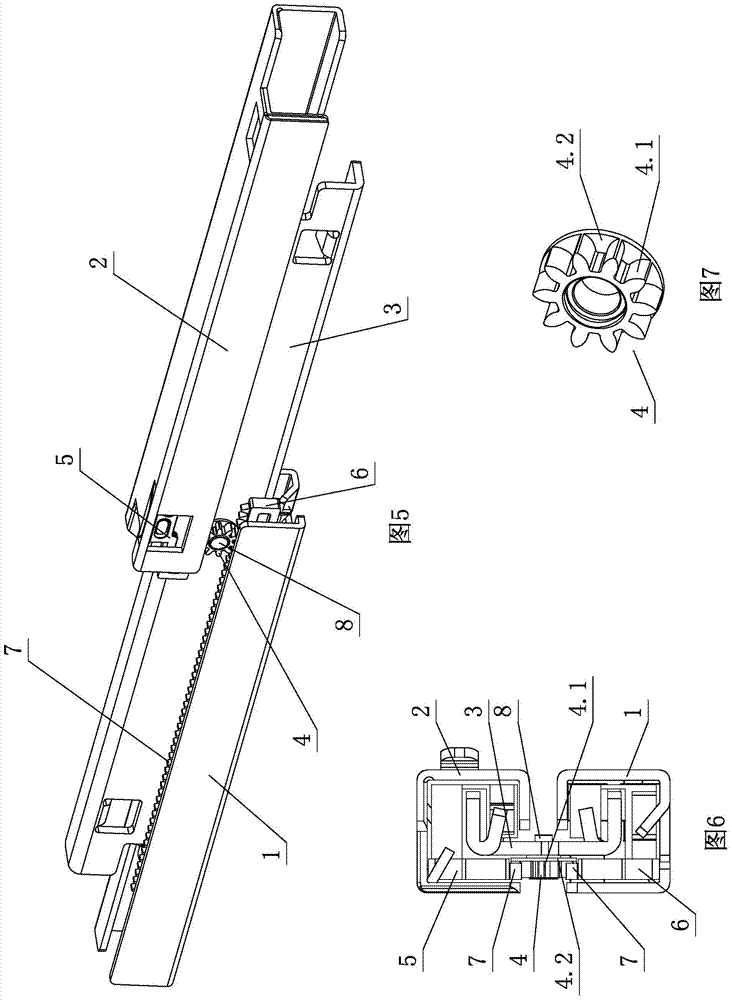

[0052] see Figure 8-Figure 10 , the position-limiting and stable structure of the drawer slide rail is different from the first embodiment in that: the left side of the gear part 4.1 is provided with a position-limiting reinforcing part 4.2 which has both position-limiting and strength-increasing functions, and the left side of the synchronous wheel 4 The side passes through the gear part 4.1 to cooperate with the limit reinforcement part 4.2 to form a left closed disc shape.

[0053] Others are not described in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com