Consecutive aging test method

A aging test and continuity technology, which is applied in the direction of power supply testing, measuring electricity, measuring devices, etc., can solve the problems of complex process management, many turnover links, and time-consuming, so as to save time, improve production efficiency, and avoid high temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

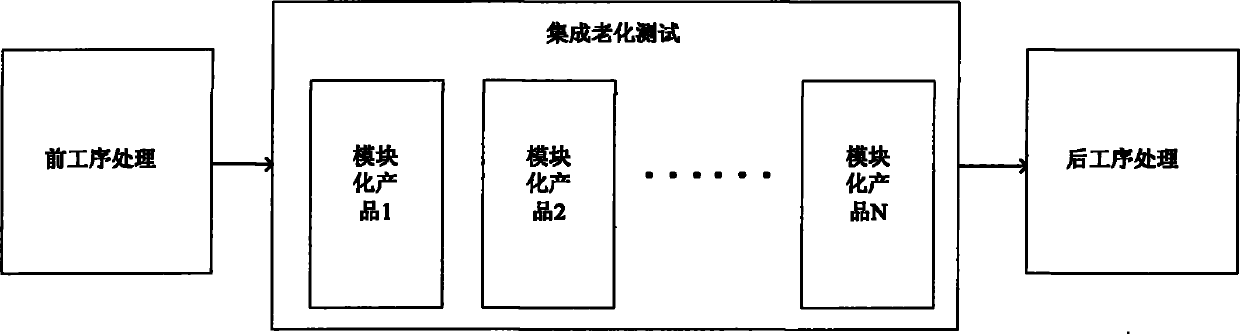

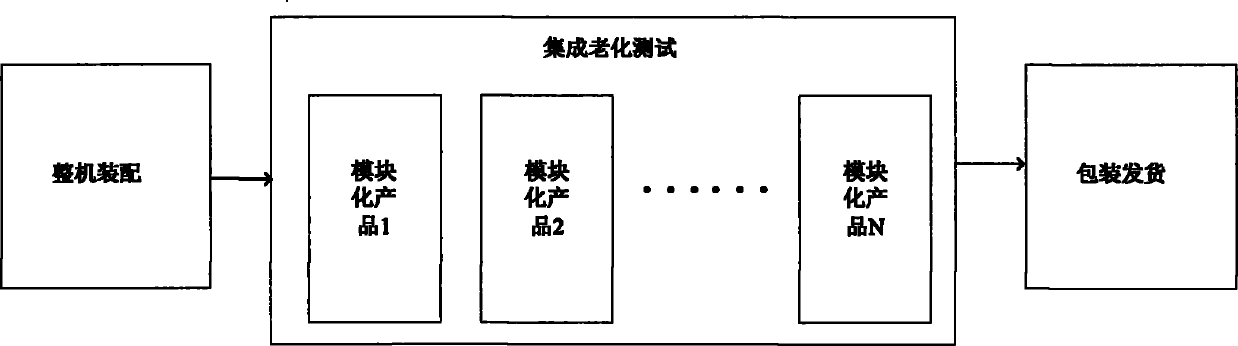

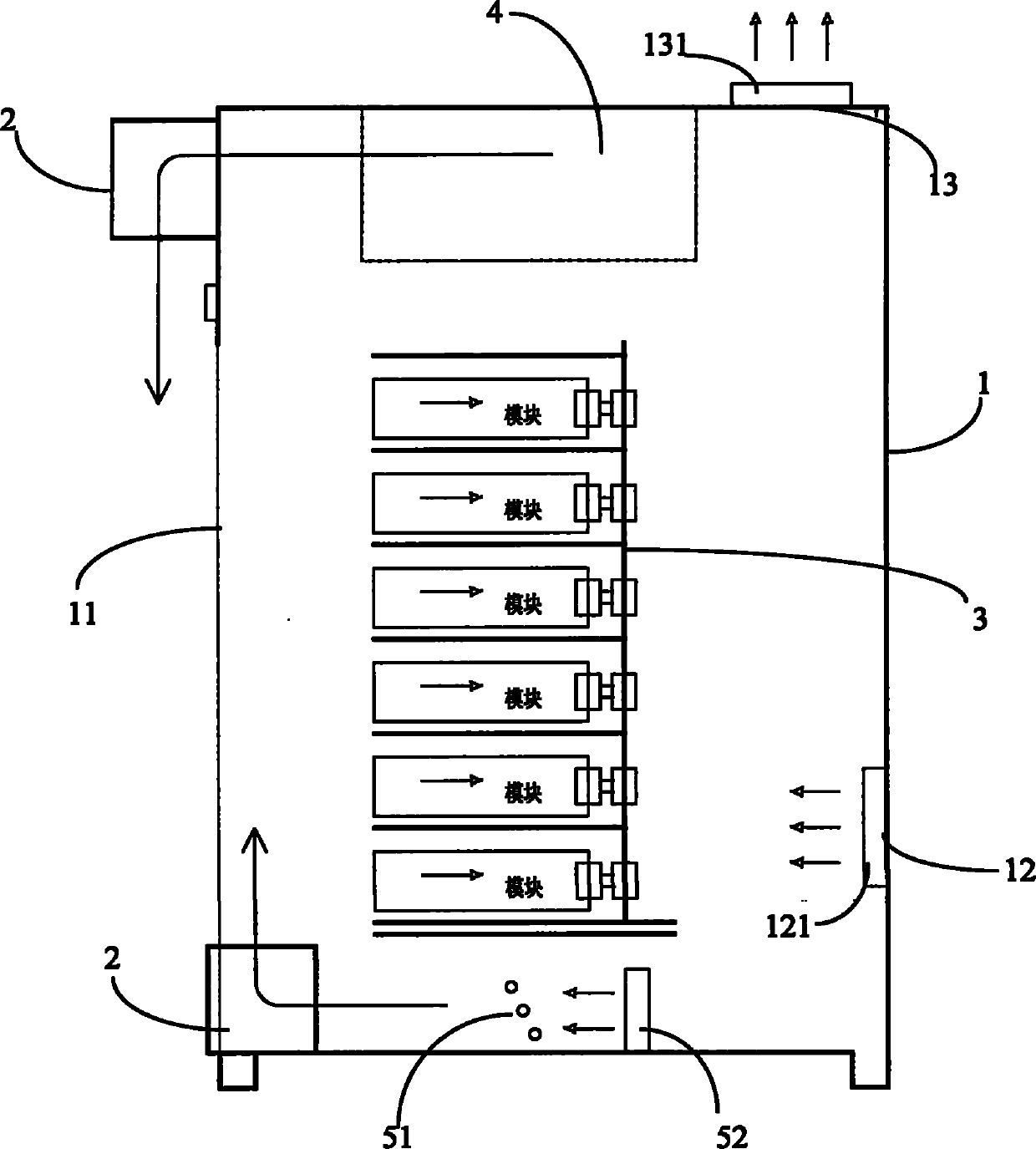

[0019] Such as figure 1 As shown, in the continuous aging test method of the present invention, it is mainly to carry out the integrated aging test to the modular product between the complete machine assembly and packaging delivery, and the integrated aging test is the test before aging, the aging test and the aging test. After aging test, some or all of these three processes are completed intensively. In the specific design, two or three processes can be completed in one test cabinet. In order to connect the integrated aging test with its previous process, N modular products are arranged to be tested in the test cabinet. , T1 is the time for processing a modular product in the previous process of the integrated burn-in test, T2 is the time for the integrated burn-in test, and the result of dividing the two is rounded down to obtain a natural number result N. Therefore, after the test of a modular product is completed in the test cabinet, a vacant space will be left in the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com