Process for producing composite molding

A manufacturing method and compound forming technology, applied in the direction of coating, etc., can solve the problems of impracticality, good composite formed products, and inability to form, and achieve the effects of excellent tightness, simple temperature control, and short forming cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

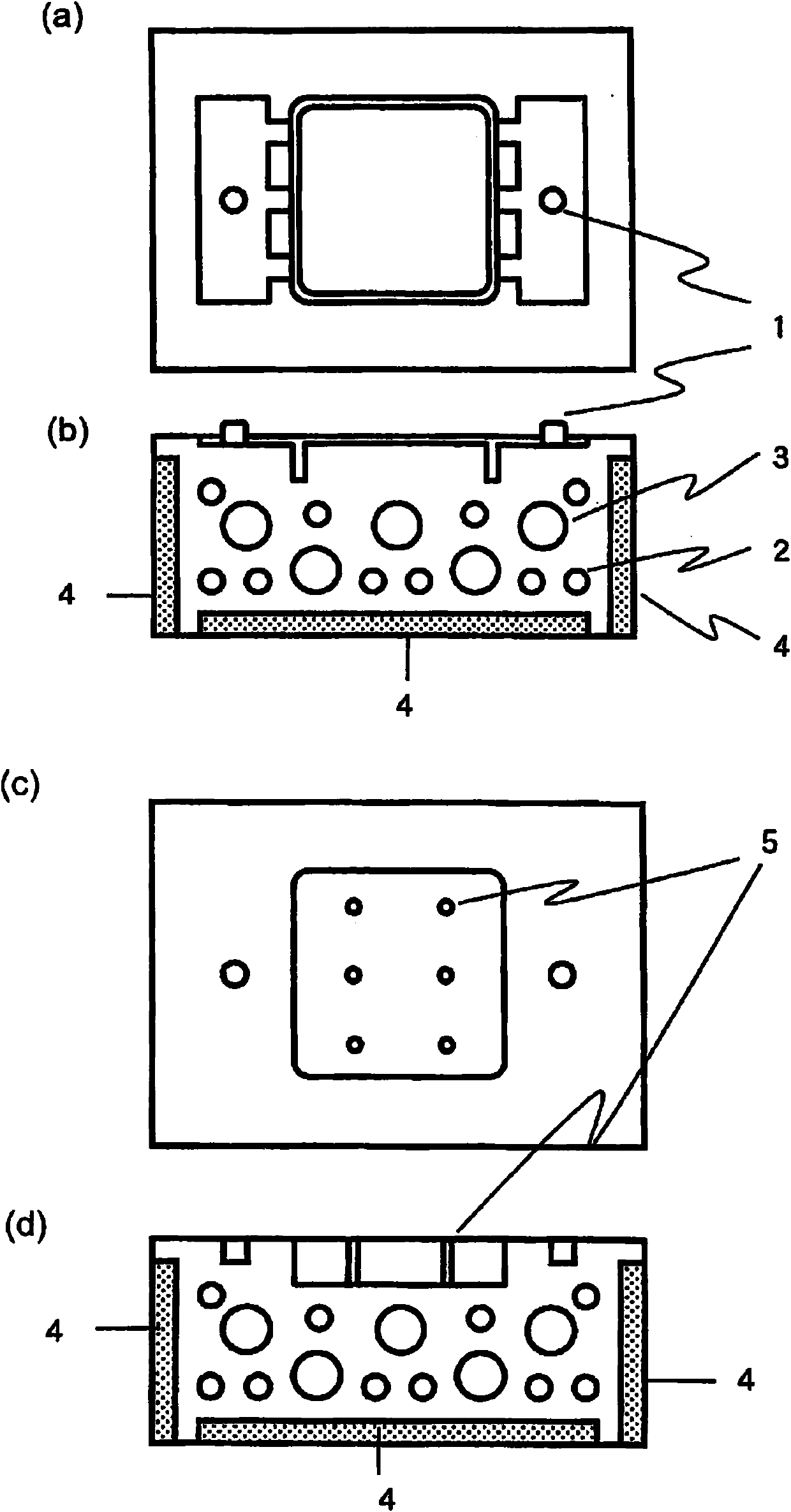

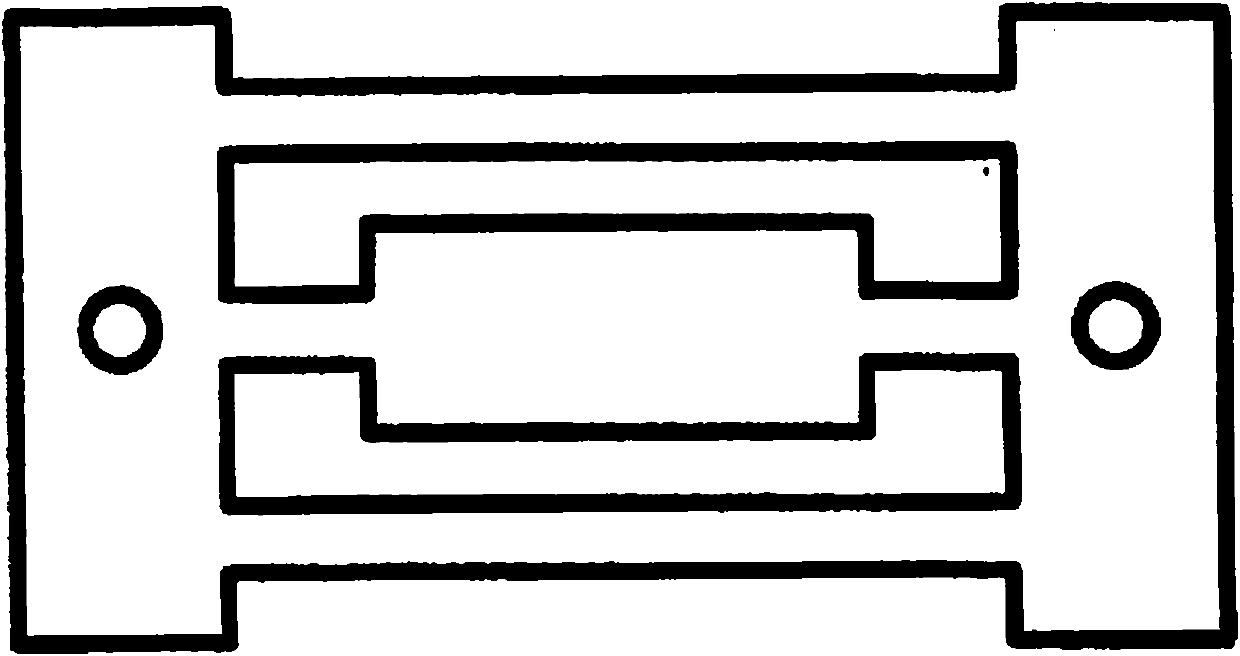

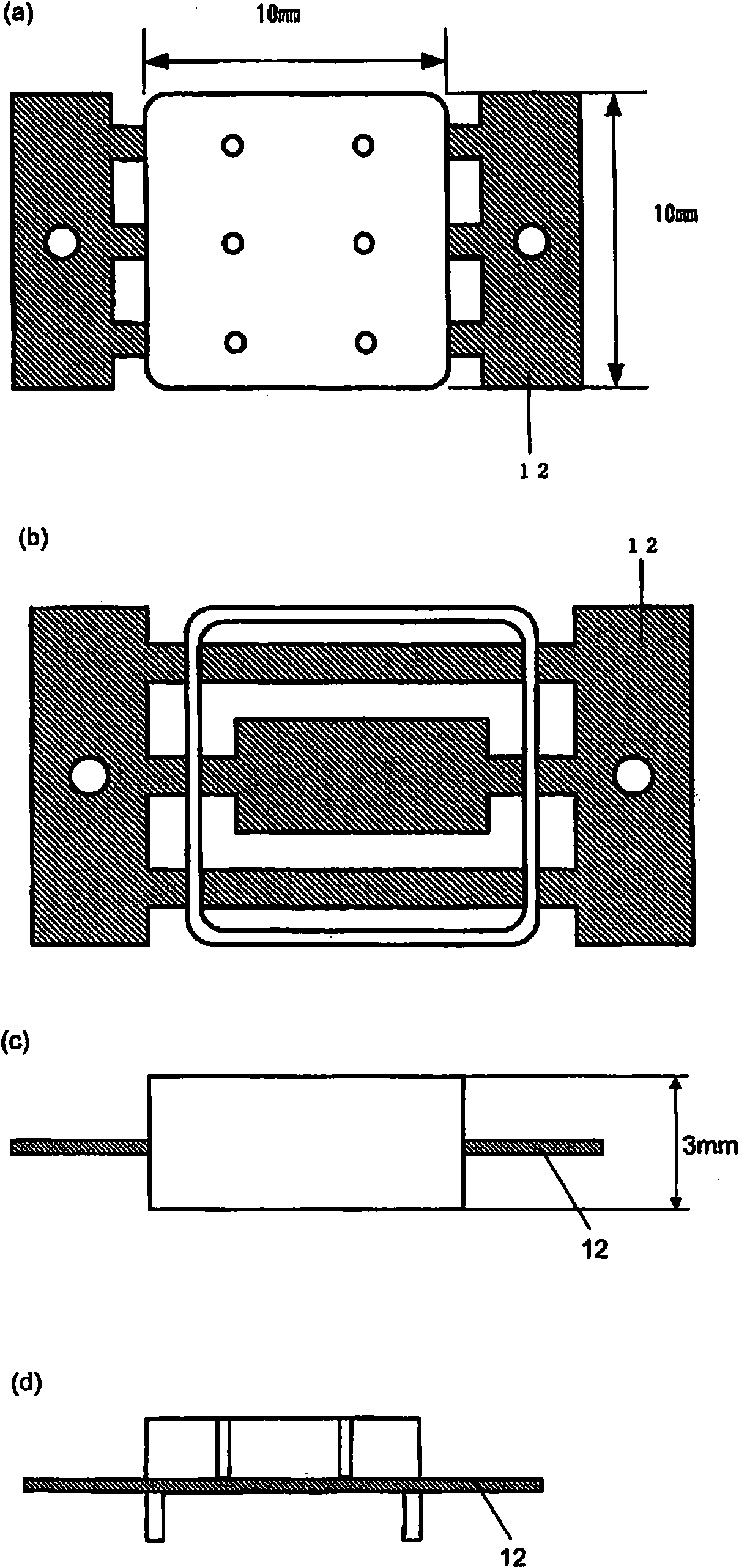

[0087] used by embedding with figure 1 Shown is a molding mold composed of a main mold of a core mold with a heating circuit and a cooling circuit. The main mold is used to control the linkage with the molding equipment. The temperature of the main mold is kept at 150°C. figure 2 Immediately after the metal parts shown were arranged in the mandrel, the temperature of the mandrel was raised from 150°C to a predetermined temperature (245°C), and it took 9.5 seconds to reach 245°C. Meanwhile, after closing the mold for molding, by injection molding the PPS resin under the following conditions, the following image 3 Such composite molded products.

[0088] Material 1 in Table 1 was used as the PPS resin.

[0089] Forming conditions

[0090] Surface treatment of the mandrel: Surface coating treatment was carried out on the steel material SUS420J2, and a diamond carbon film (DLC) with a thickness of 1.0 μm was applied. The surface roughness was as follows: the ten-point aver...

Embodiment 2

[0107] Molding and evaluation were performed in the same manner as in Example 1 except that Material 2 in Table 1 was used as the PPS resin.

Embodiment 3

[0109] Molding and evaluation were performed in the same manner as in Example 1 except that the core mold temperature during injection molding was 200°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com