Control method for improving stability of moisture content of cut tobaccos

A technology of stability control and moisture content, applied in tobacco, tobacco preparation, tobacco treatment, etc., can solve the problems of excessive shredded tobacco, deviation, etc., and achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

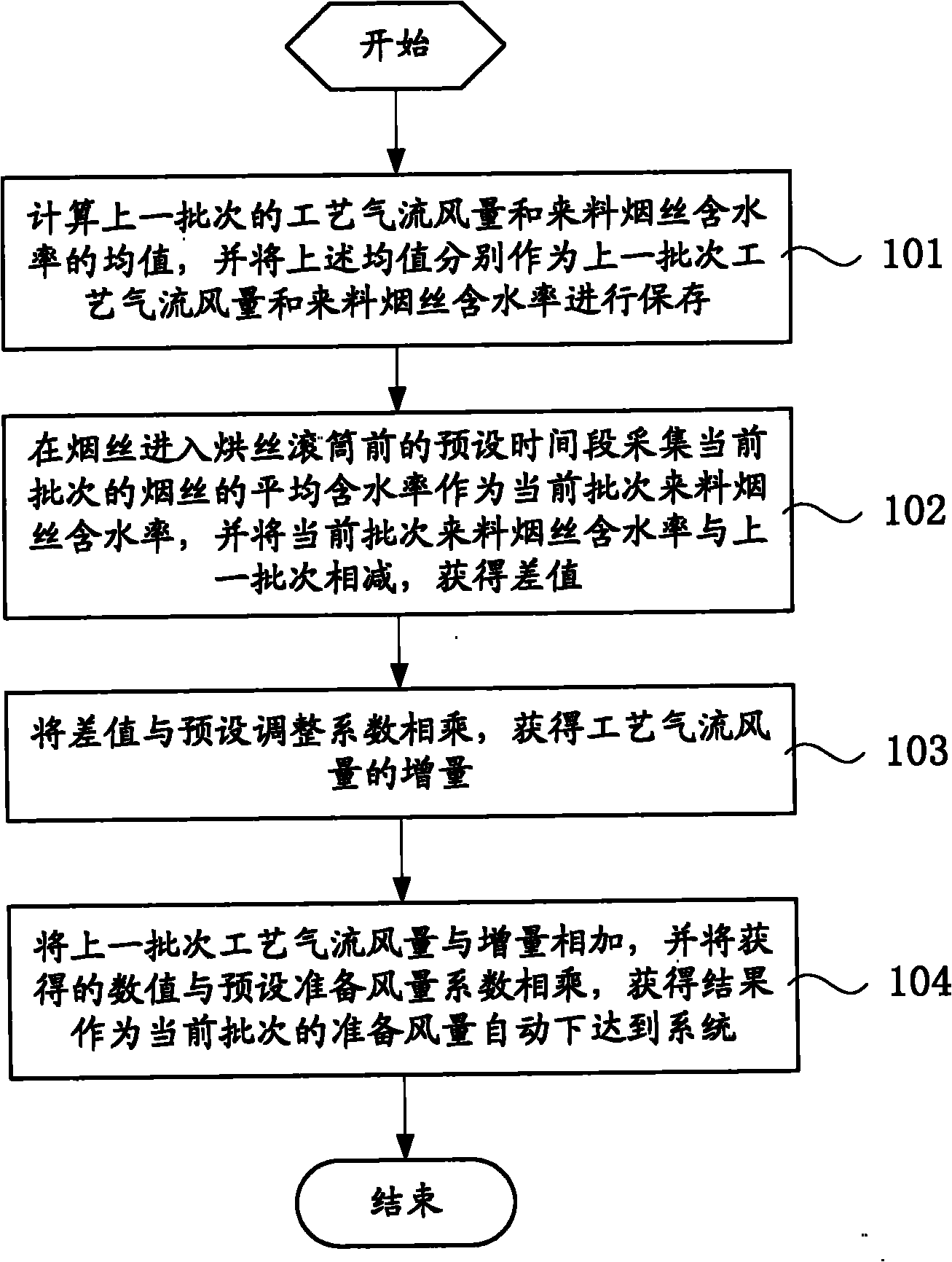

[0041] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

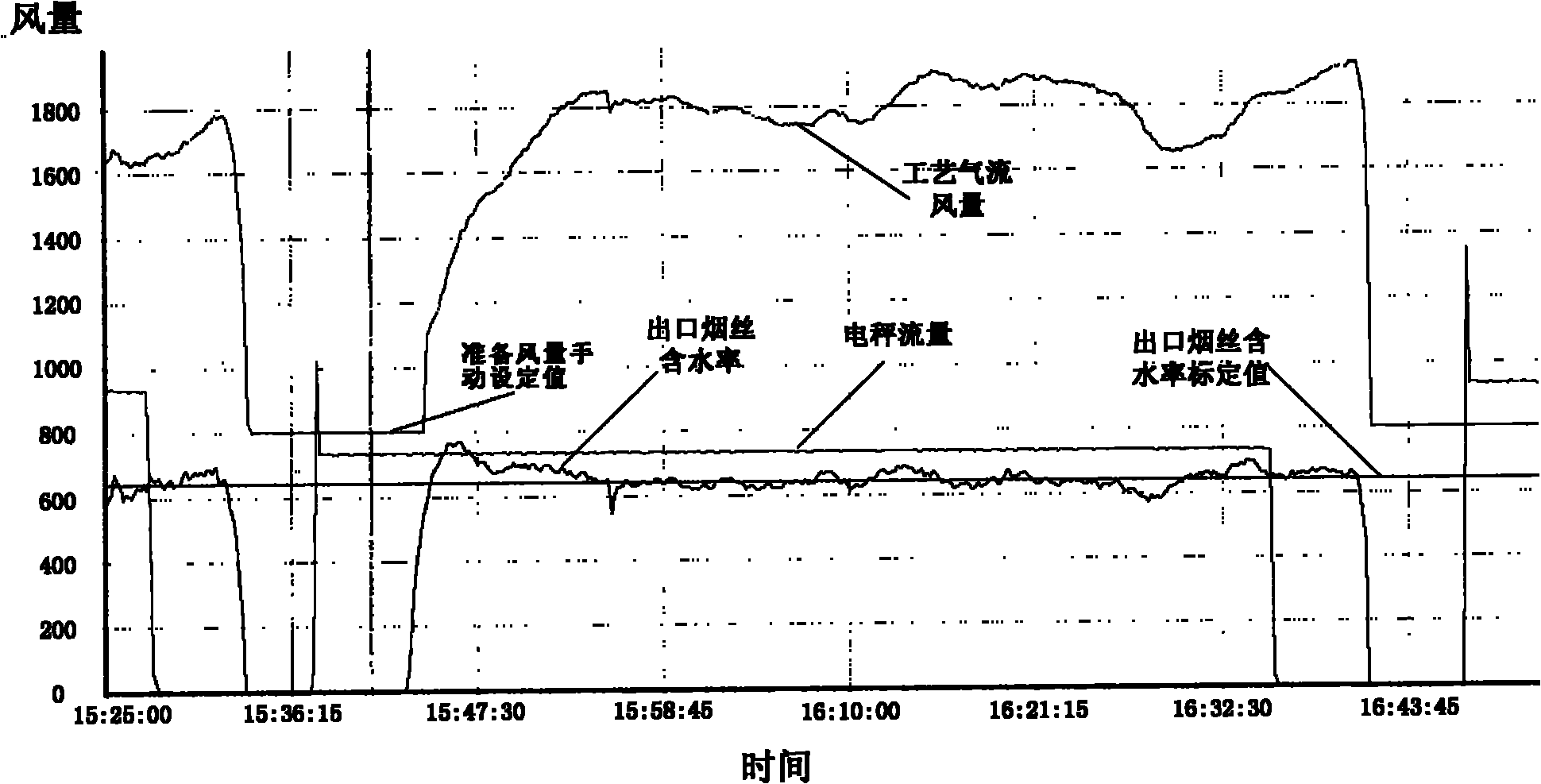

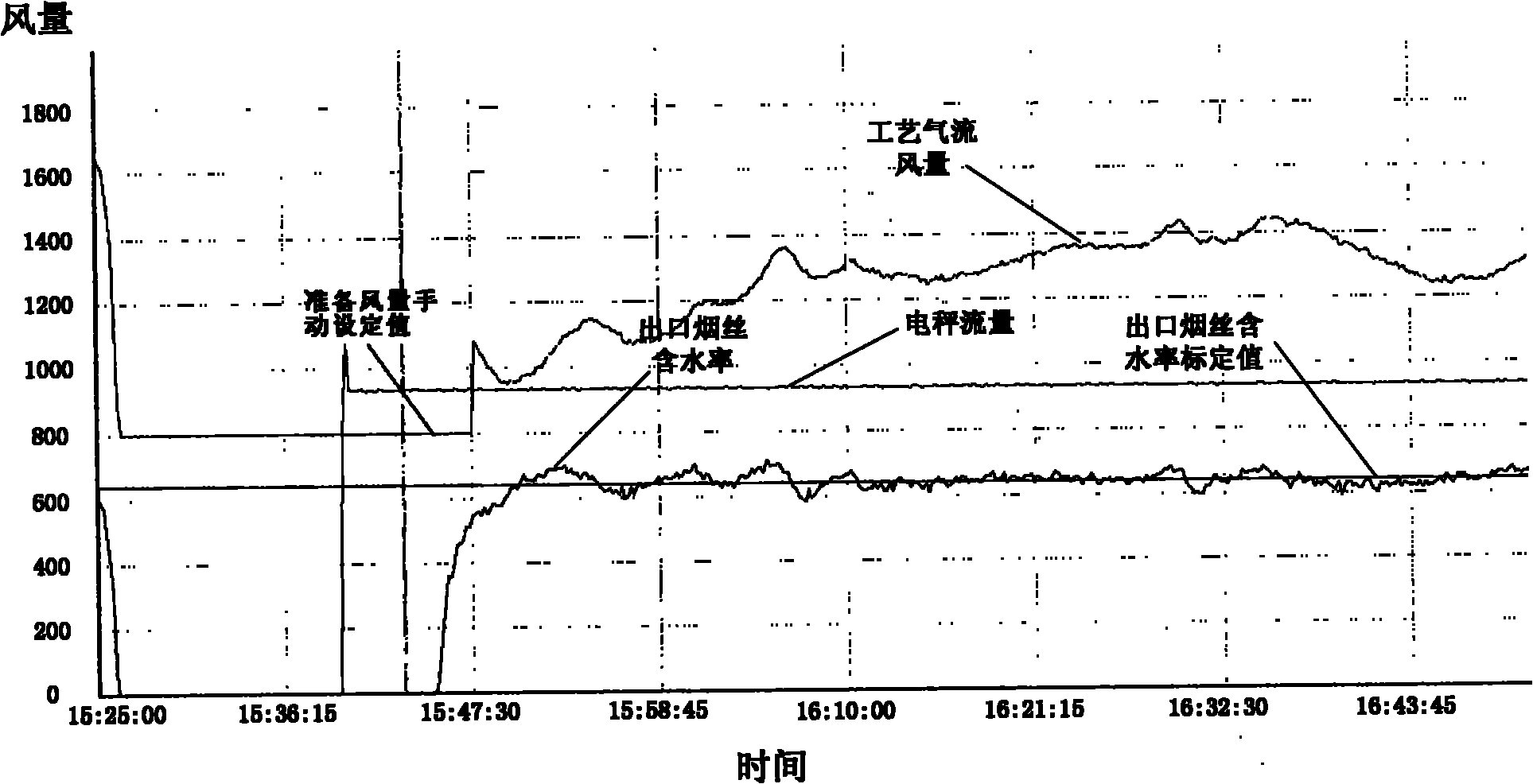

[0042] In the actual production process, the inventors often found that the moisture content of the incoming cut tobacco, the flow rate of the incoming cut tobacco, and the formula for processing the cut tobacco did not change in the external factors, but the air volume of its process airflow had a great change. After long-term follow-up research It is found that it is mainly due to the influence of weather and climate, so that it is necessary to track the air volume of the process airflow of the silk drying machine frequently. If there is any change, it is necessary to manually set the air volume in time, so that the system can quickly enter a stable state and reduce the generation of unqualified shredded tobacco .

[0043] However, the manual setting of the preparation air volume is inaccurate and depends on the expe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com