Electric iron

A technology of electric soldering iron and soldering iron, applied in the direction of soldering iron, metal processing equipment, manufacturing tools, etc., can solve the problems of easy fatigue of fingers, inability to operate power wires, etc., and achieve the effect of flexible and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

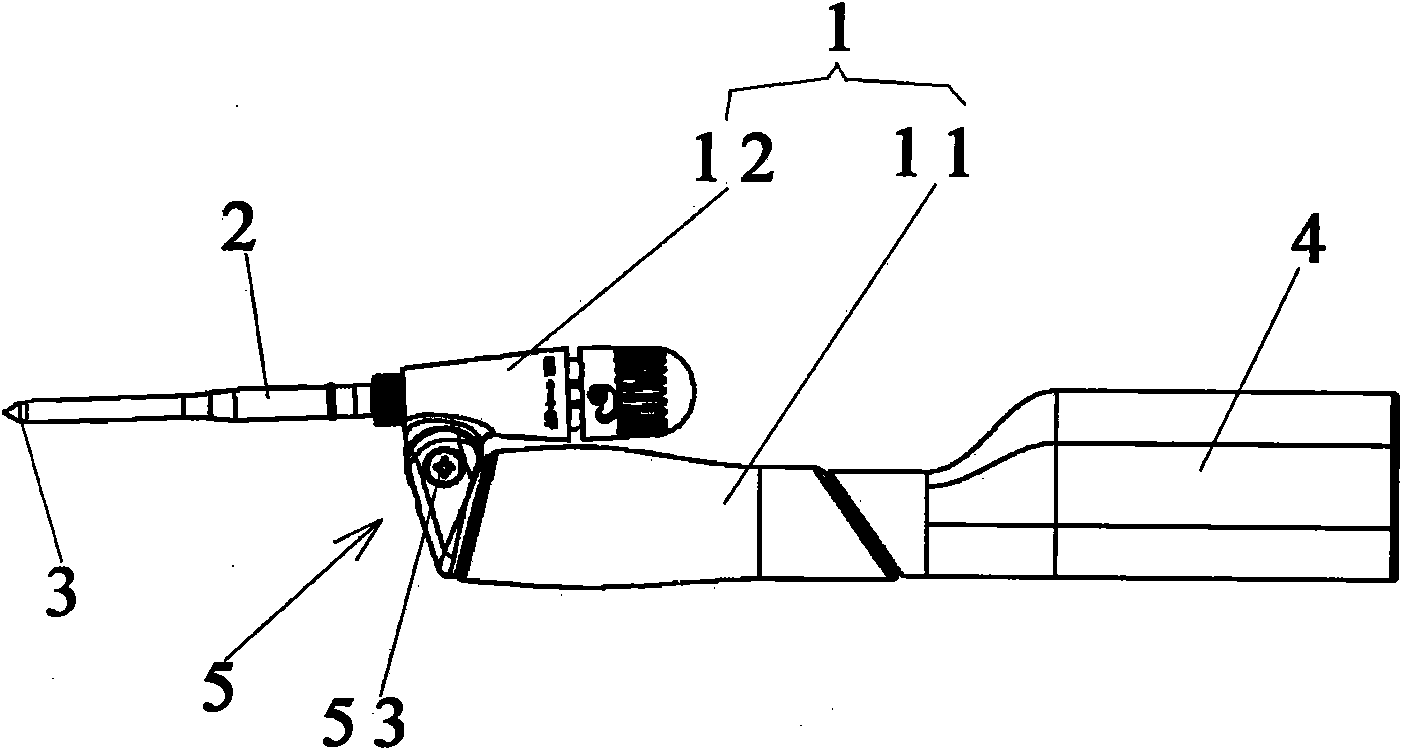

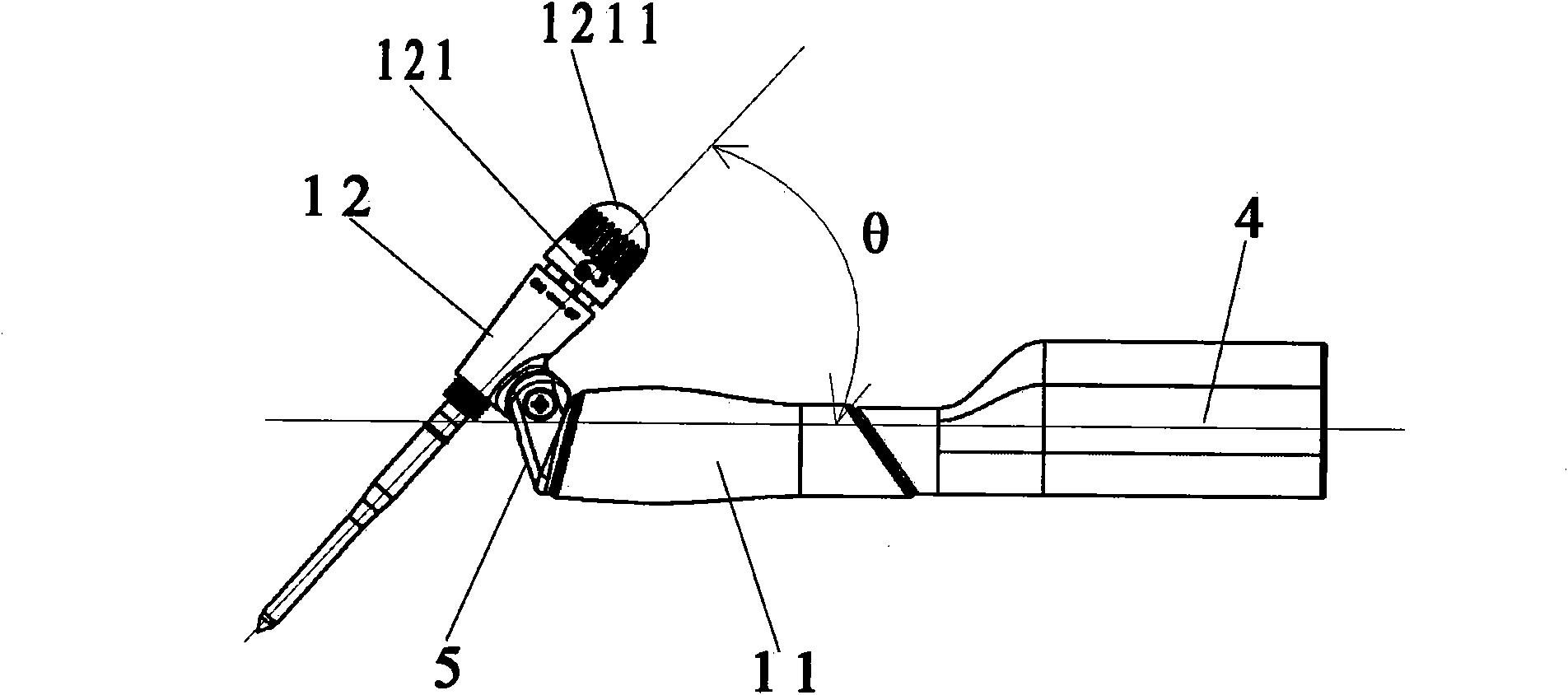

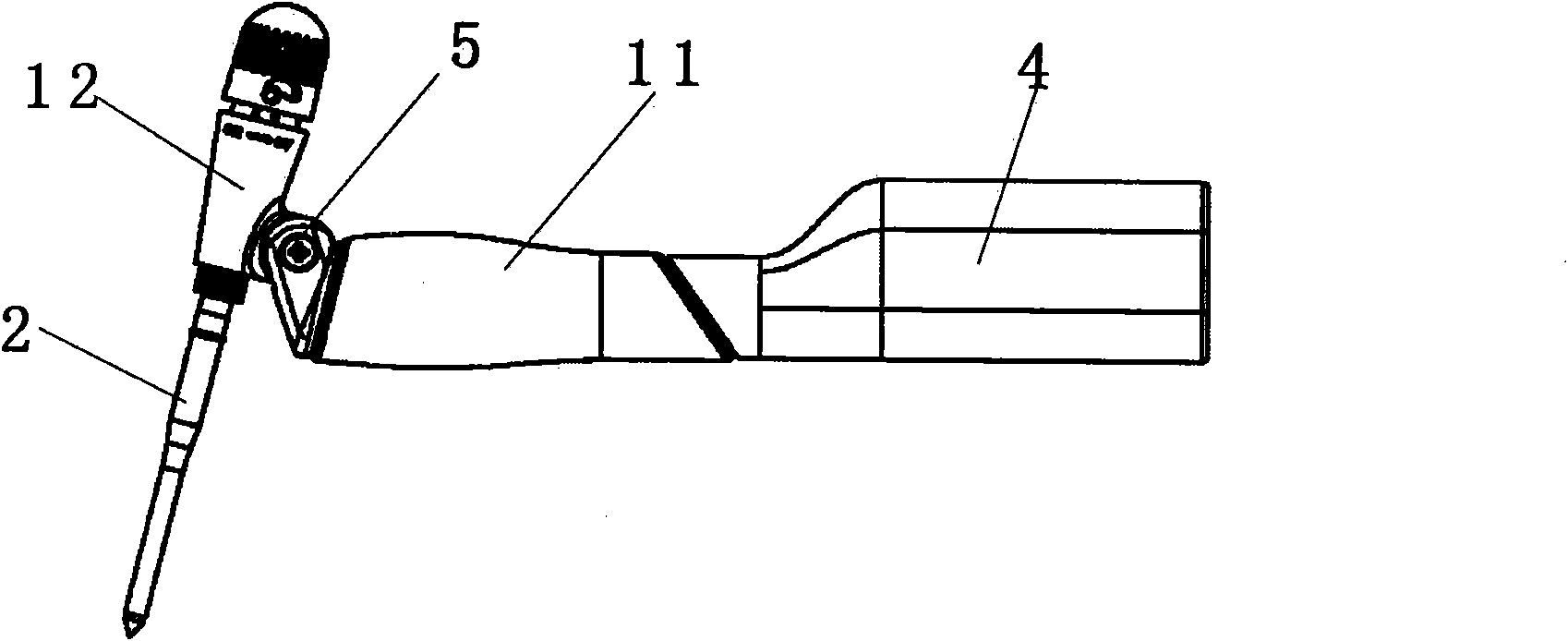

[0022] Below in conjunction with accompanying drawing and preferred specific and embodiment, the structure of the present invention is described further:

[0023] refer to figure 1 , figure 2 and image 3 As shown in , the present invention includes: a soldering iron handle 1 , a soldering iron rod 2 and a soldering iron tip 3 . The soldering iron handle 1 is composed of two parts, the handle body 11 and the handle head 12. The handle body 11 is the part held by the hand during operation. The shape of 11 is a streamline structure designed according to the principle of ergonomics; the handle 12 is in the shape of a circular platform, the soldering iron rod 2 and the handle 12 are on the same straight line, the front end of the soldering iron rod 2 is connected with the soldering iron tip 3, and the tail of the soldering iron rod 2 The end is connected on the front end of the crown 12, which is also the upper bottom surface of the round table. The rear end of the crown 12 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com