Automatic winder

A winding machine and automatic technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of coil chaos, difficulty in passing the performance test of finished products, and unsightly appearance, so as to achieve high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

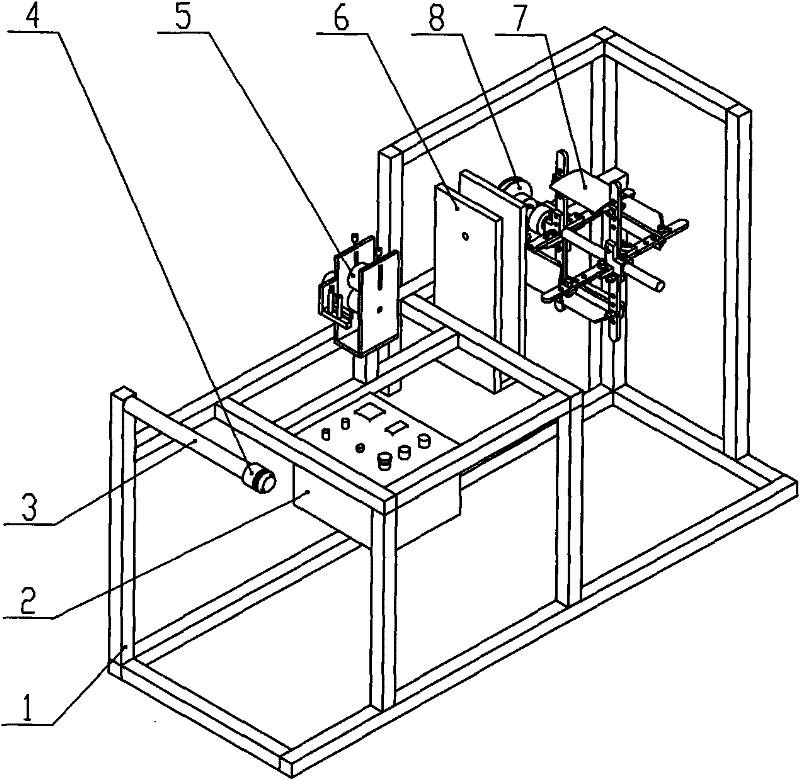

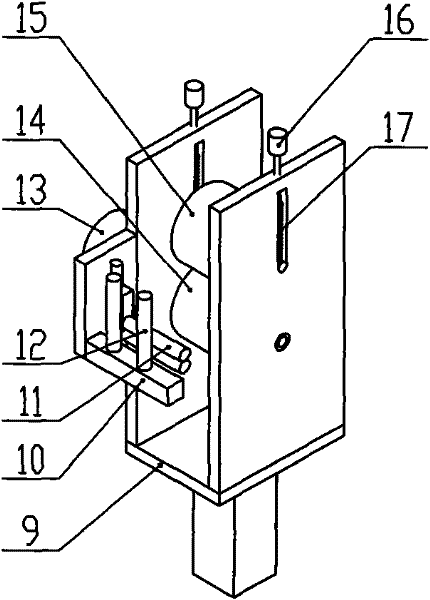

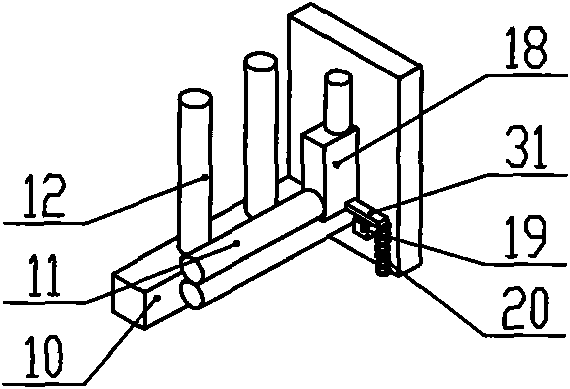

[0022] Figure 1 to Figure 8 Including frame 1, electrical control box 2, raw material installation shaft 3, quick clamping shaft buckle 4, length measuring mechanism 5, shearing mechanism 6, winding mechanism 7, motor 8, coding wheel seat 9, roller seat 10 , horizontal roller 11, vertical roller 12, encoder 13, driving wheel 14, driven wheel 15, adjusting bolt 16, compression spring 17, slide rail 18, travel switch 19, extension spring 20, scissors bracket 21, threading Hole 22, scissors 23, cylinder 24, wheel plate 25, spoke rod 26, movable hub 27, wheel axle 28, adjustment hole 29, winding reel 30, switch trigger plate 31, fixed hub 32 etc.

[0023] Such as figure 1 As shown, the present invention is an automatic wire winding machine, including a frame 1 made of aluminum alloy profiles. A raw material installation shaft 3 , a length me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com