Double-deck elevator

A technology for double-deck elevators and elevator cars, which is used in elevators, lifts, transportation and packaging in buildings, can solve the problems of short service life of screw shafts, and achieve the purpose of prolonging service life, improving driving efficiency and improving efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

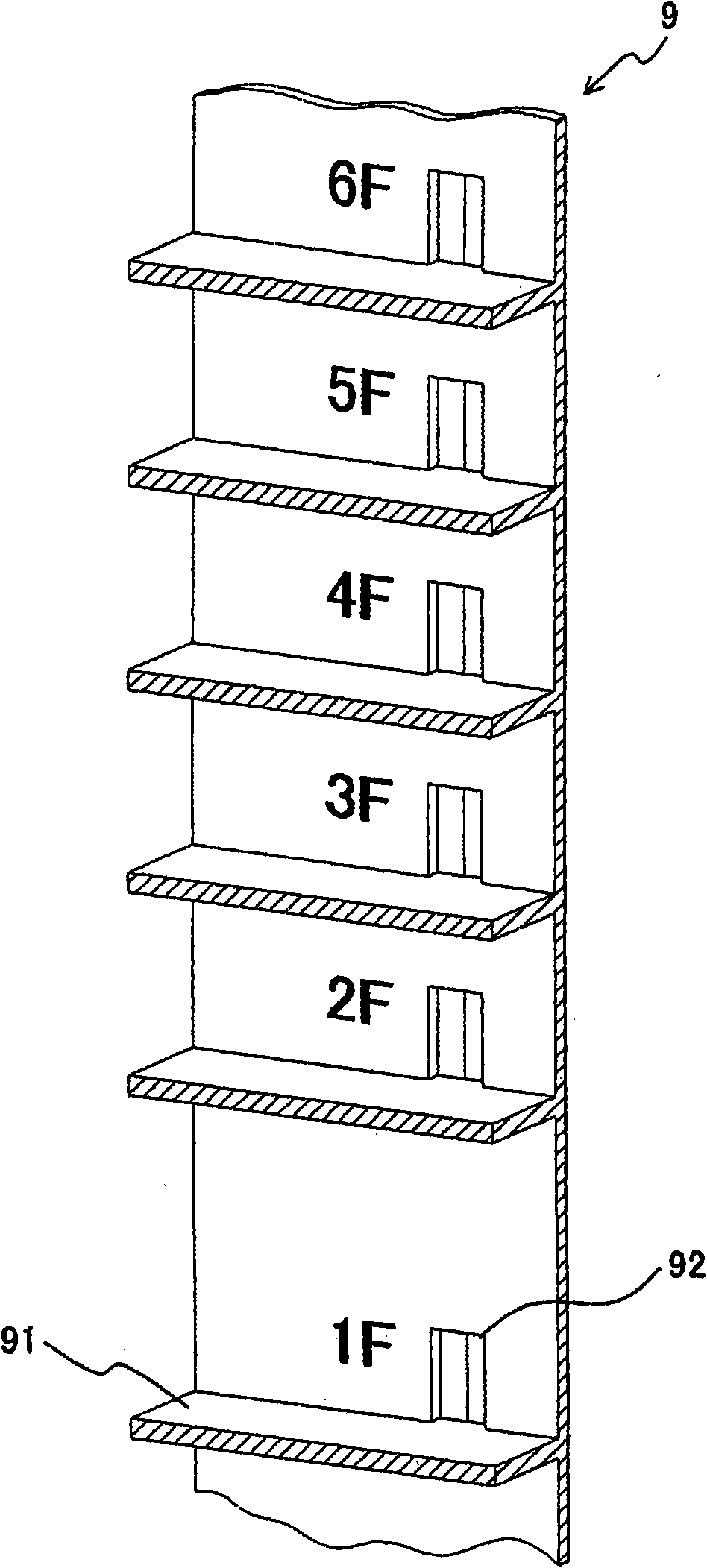

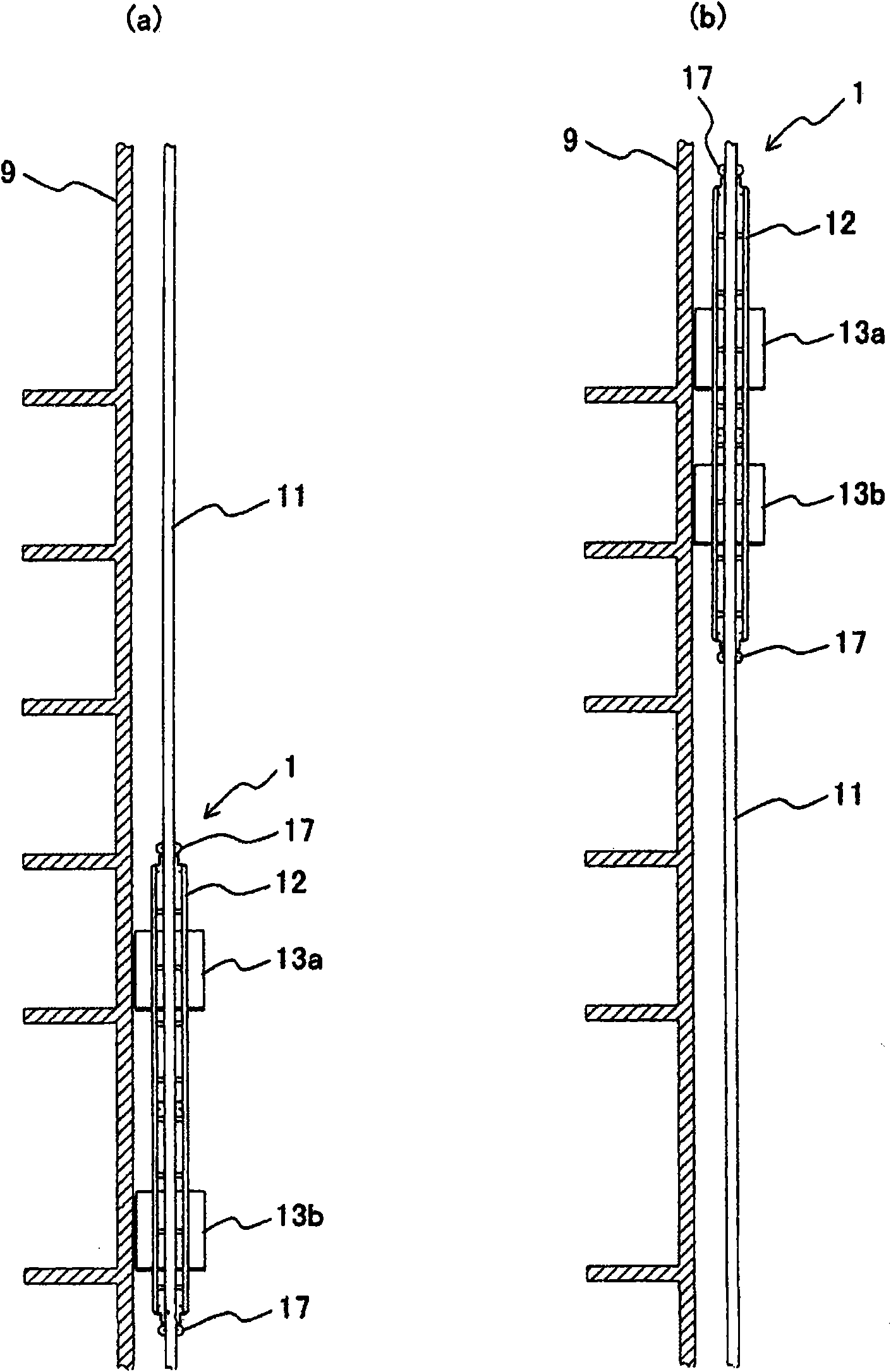

[0072] Figure 1 to Figure 9 It is an example of this invention, and shows 1st Embodiment.

[0073] figure 1 A part of walls and floors near the elevator lobby of a building in which the double-deck elevator of the present invention is installed are shown. The building 9 has a floor slab 91 on each floor, and a floor-side elevator door 92 for entering an elevator car on each floor. The floor height of the first floor of the building 9 is higher than that of other floors, for example, the distance between the upper car and the lower car when the lower car of a double-deck elevator stops on the first floor and the upper car stops on the second floor The interval between the upper car and the lower car is different when the lower car stops on the fifth floor and the upper car stops on the sixth floor.

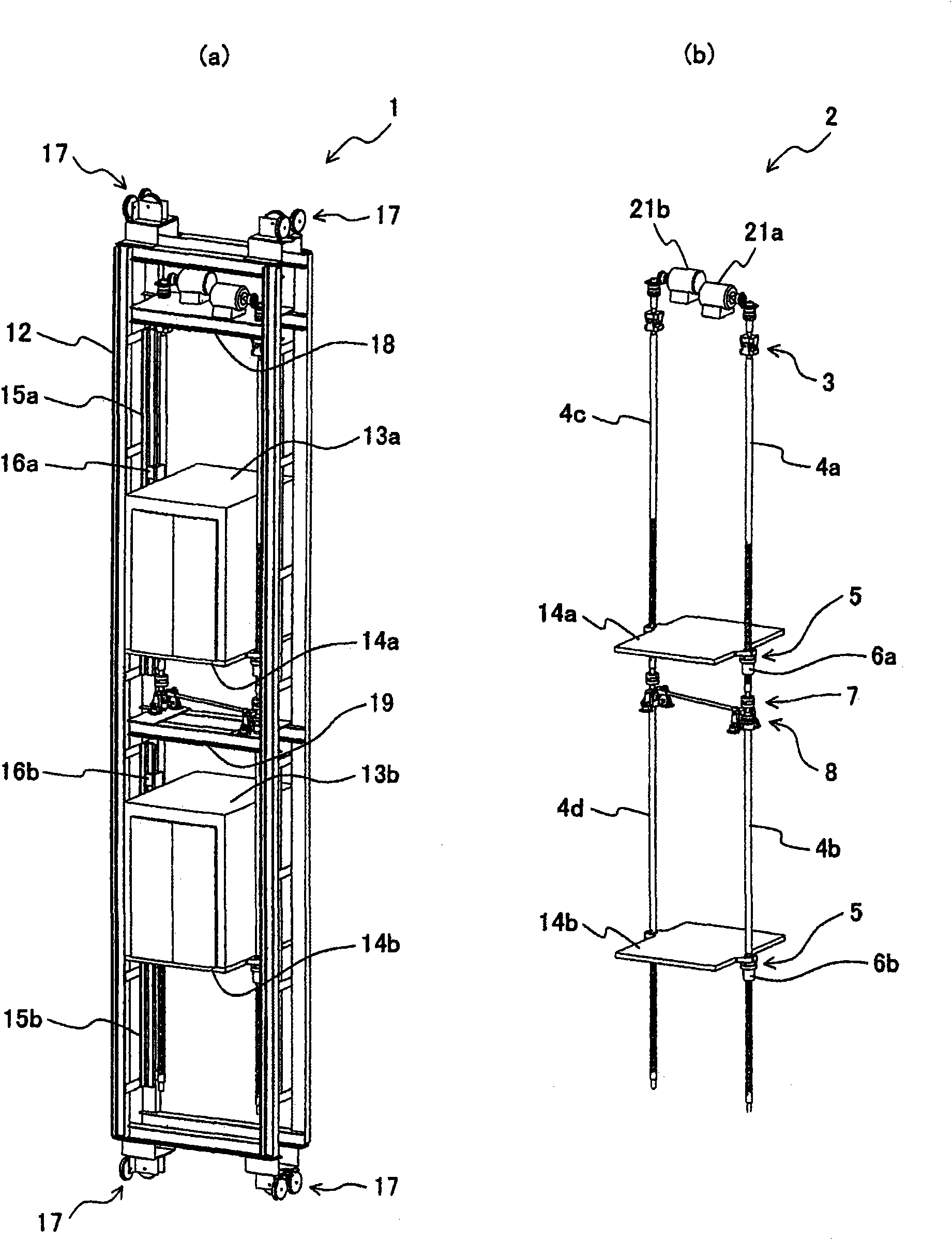

[0074] figure 2 right figure 1 The shown building 9 and the double-deck elevator 1 arranged in this building 9 are illustrated. figure 2 The double-deck elevator 1 in has ...

Embodiment 2

[0105] Figure 10 to Figure 12 The second embodiment of the present invention is shown. Compared with the first embodiment, the second embodiment has the following differences. In the second embodiment, a differential gear mechanism is used instead of two induction motors, and two universal joint mechanisms and sliding keys are used instead Oldham coupling, and using a balance mechanism as a supporting load equalizing mechanism, etc., but the function of the second embodiment is the same as that of the first embodiment. Hereinafter, it demonstrates centering on the part which differs from 1st Embodiment, referring drawings.

[0106] Figure 10 The drive section using the differential gear mechanism is shown in the figure. The driving section has a driving motor 210 and a differential gear mechanism 211 , and the rotational torque generated by the driving motor 210 is equally distributed left and right through the differential gear mechanism 211 and transmitted to the rotati...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap