Clean pulping of rhus chinensis twigs and comprehensive utilization method thereof

A clean pulping and salt-skinned wood technology, applied in textiles and papermaking, papermaking, fiberboard, etc., can solve problems such as waste, achieve the effects of reducing production costs, reducing pollution, and broad economic prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

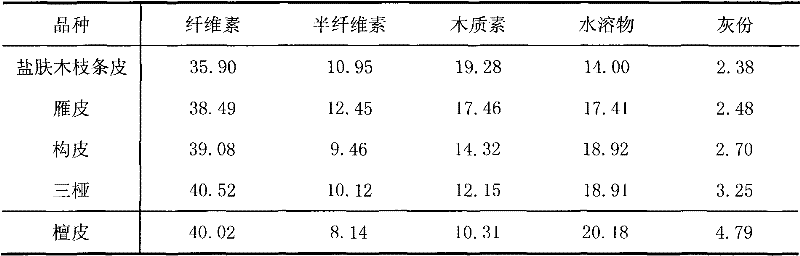

Image

Examples

Embodiment 1

[0026] (1) Steam explosion: peel the collected twigs of Saltina twigs under the condition that the solid-to-liquid mass ratio is 1:3, and the treatment time is 30 minutes, then peel off the skins, separate the skins and rods, and then put the skins under a pressure of 0.8 MPa Maintain pressure for 5 minutes for steam explosion treatment;

[0027] (2) Extraction of functional components: wash the steam explosion material with water, combine the boiling liquid and the steam explosion washing liquid, and make a solution with a concentration of about 6%, slowly flow into the macroporous adsorption resin, wash with 2 times distilled water after loading Then eluted with 3 times of 40% ethanol, collected the eluate, concentrated at normal pressure, then concentrated under reduced pressure to distill off the solvent, and dried in vacuum below 80°C to obtain crude tannin compound;

[0028] (3) Beating: fly knife rotor 2000 rpm, pulp tank 2000 rpm, beating 30s;

[0029] (4) Bleaching: ...

Embodiment 2

[0034] Embodiment 2: (1) steam explosion: peel the bark after boiling the collected twigs, then carry out steam explosion treatment to the bark under 1.0Mpa pressure for 5min;

[0035] (2) Extraction of functional components: Wash the raw materials after steam explosion, recover the functional components adsorbed on the surface of the fiber, combine the boiling liquid and steam explosion washing liquid, and make a solution with a concentration of about 6%, and slowly flow into the large Pore adsorption resin, elute with 2 times of distilled water after loading on the column, and then elute with about 3 times of 70% ethanol, collect the eluate, first atmospheric pressure and then vacuum concentration, evaporate the solvent, and vacuum dry below 80 °C , to obtain crude flavonoids;

[0036] (3) Beating: fly knife rotor 1400 rpm, pulp tank 1400 rpm, beating 60s;

[0037] (4) Steam explosion salt skin veneer bleaching: using two-stage bleaching technology, the composition of the...

Embodiment 3

[0042] Embodiment 3: (1) steam blasting: peeling after the poaching of the collected chrysanthemum branches, and then carrying out the steam explosion treatment to the chrysanthemum bark under the pressure of 1.2Mpa for 3min;

[0043] (2) Extraction of functional components: Recover the steam explosion residual liquid produced after steam explosion treatment, and at the same time wash the raw materials after steam explosion to recover the functional components adsorbed on the fiber surface, combine the steam explosion residual liquid and washing liquid, and prepare Make a solution with a concentration of about 6%, slowly flow into the macroporous adsorption resin, elute with 2 times of distilled water after loading, and then elute with about 3 times of 40% solvent, collect the eluent, first at normal pressure and then under reduced pressure After concentrating and evaporating the solvent, vacuum-dry below 80°C to obtain crude tannin.

[0044] (3) Beating: 1000 rpm of the flyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com