Tertiary feeding method for mixing water permeable cement concrete on site

A technology of cement concrete and material feeding method, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of low strength and poor water permeability of water permeable cement concrete, and achieve the effect of improving strength and water permeability.

Inactive Publication Date: 2011-06-15

青岛建设集团零零一工程有限公司 +1

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

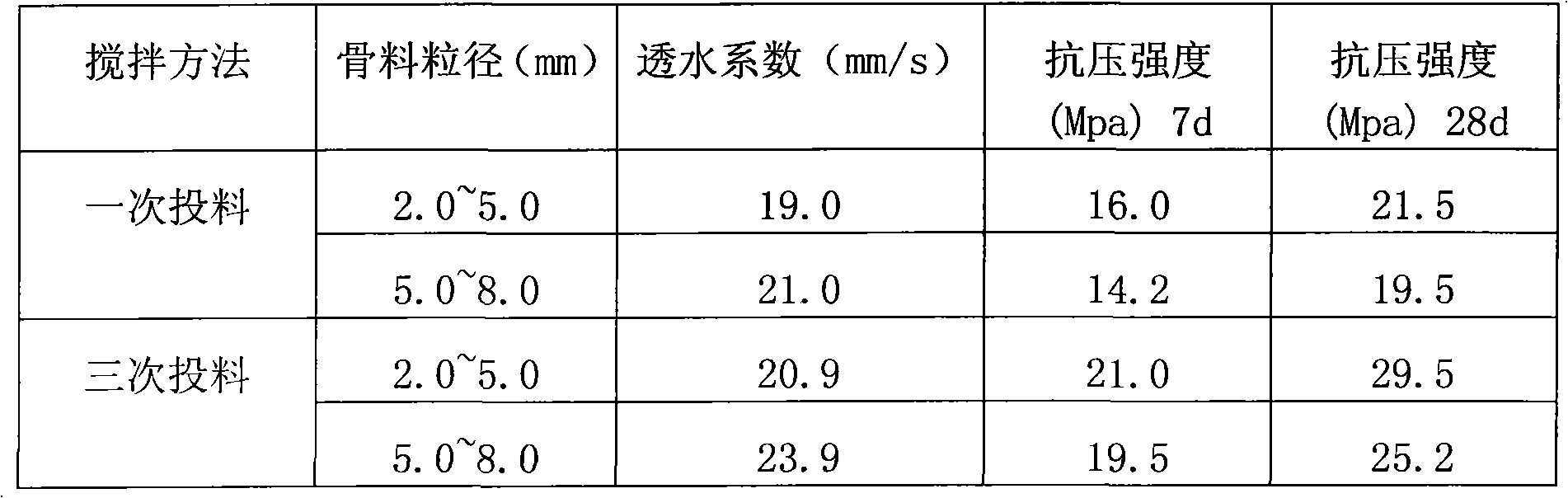

In view of the deficiencies in the prior art, the technical problem to be solved by the present invention is to provide a three-time feeding method for on-site mixing of permeable cement concrete, so as to solve the problem of low strength and water permeability of permeable cement concrete due to the one-time feeding method. sex problem

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

The invention discloses a tertiary feeding method for mixing water permeable cement concrete on site. The method comprises the following steps: (1) firstly premixing 100% of aggregate and 70% of mixing water; (2) then adding 50% of cement and all admixtures for mixing; and (3) finally adding the remaining 50% of cement and 30% of mixing water to an agitator. In the method, materials such as the aggregate, the cement, the water, the admixtures and the like are mixed by the tertiary feeding method, which solves the problems of the water permeable cement concrete such as low strength and poor water permeability caused by a primary feeding method, and effectively improves the strength and water permeability of the water permeable cement concrete, thus being favorable for popularization and application.

Description

Three feeding method for on-site mixing of permeable cement concrete technical field The invention relates to an on-site preparation method of concrete, in particular to an on-site preparation method of permeable cement concrete, belonging to the technical field of building materials. Background technique The permeable cement concrete adopts the conventional feeding method (one-time feeding) during the on-site preparation process, that is, aggregate, cement, water, admixtures, etc. are added to the mixer and stirred together. mixing method), but the prepared concrete tends to have low strength and poor water permeability. The main reasons are as follows: 1. The permeable cement concrete is mixed with one-time feeding, and the contact surface between the aggregate and the cement paste is not uniform, resulting in incomplete wrapping of the aggregate by the cement paste, and the bonding effect of the cement paste cannot be well exerted , which directly affects the strength...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Applications(China)

IPC IPC(8): E04G21/02

Inventor 张明平黄少瑜李文涛

Owner 青岛建设集团零零一工程有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap