Novel helical gear-worm gear speed reducer

A worm gear, helical gear technology, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of large vibration and noise, large transmission ratio grading interval, increased temperature rise, etc., and achieves various installation forms. The effect of optimization, wide speed ratio range and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

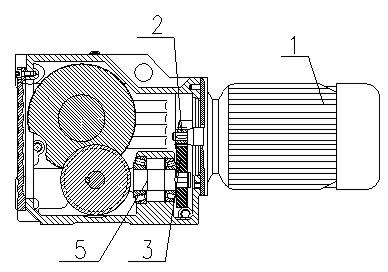

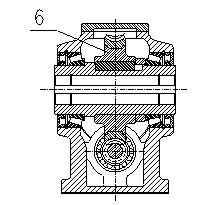

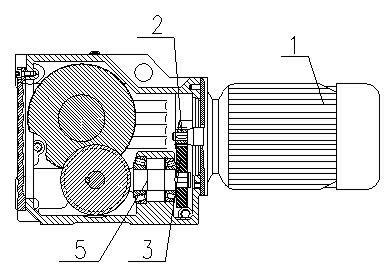

[0011] The structural features of the present invention will be further elaborated below in conjunction with the accompanying drawings.

[0012] like figure 1 and figure 2 The new helical gear-worm gear reducer shown includes motor 1, first-stage pinion gear 2, first-stage large gear 3, box body, worm 4 and worm gear 5, flange, bearing, oil seal, retaining ring, oil seal ring, keys and fasteners, the motor 1 is installed on the input side of the box through the flange cover and fasteners, the output shaft of the motor 1 is fixed to the first-stage pinion 2 through the key, and the first-stage pinion 2 The first-stage large gear 3 is meshed; the first-stage large gear 3 is fixed on the pillow block of the second-stage gear shaft 4 through a key; the two ends of the second-stage gear shaft 4 are bearing blocks and are equipped with bearings, and the middle part is fixed with a worm 5 ; The worm 5 is engaged with the worm wheel 6 arranged above, and the worm wheel 6 is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com