Forming method of complex prefabricated part made of metal sweating material

A prefabricated part and metal technology, applied in the field of forming metal sweating material prefabricated parts, can solve the problems of uncontrollable pore size, distribution shape, limited release of material application potential, single material distribution form, etc., to achieve optimized paving effect , the effect of promoting and expanding the ratio range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In the present embodiment, a kind of tungsten copper nozzle throat lining preform is prepared by adopting the forming method of the complex preform of metal sweating material:

[0043] (1) Selection and processing of raw materials; ① Determine the high melting point tungsten as the preform material and the low melting point copper as the infiltration material; ② Coat a layer of copper with a thickness of 2um on the surface of the spherical tungsten powder.

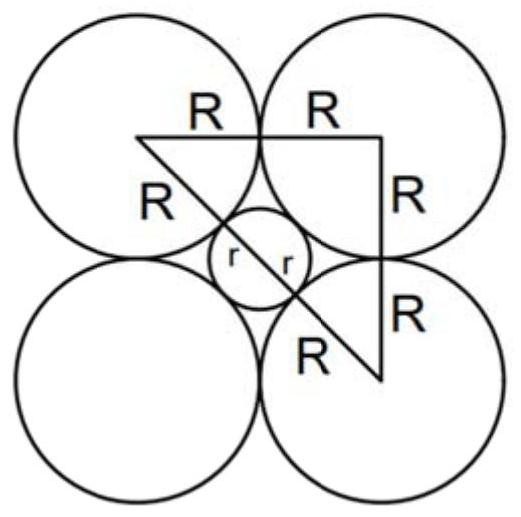

[0044] (2) Structural design and processing of prefabricated parts; ①According to the target composite material component ratio and performance requirements, determine the porosity of the prefabricated part to be 20%, and design the pore size of 12um, circular holes, and uniform distribution to obtain a three-dimensional model of the prefabricated part ;2 Process the three-dimensional model of the prefabricated part according to the characteristics of the laser selective melting process, and output the process model....

Embodiment 2

[0049] In the present embodiment, a tungsten-silver contact preform is prepared by a method of forming a complex preform of metal sweating material:

[0050] (1) Selection and processing of raw materials; ① Determine the high melting point tungsten as the preform material and the low melting point silver as the infiltration material; ② Apply a layer of silver with a thickness of 3um on the surface of the spherical tungsten powder.

[0051] (2) Structural design and processing of prefabricated parts; ①According to the target composite material component ratio and performance requirements, determine the porosity of the non-functional area of the prefabricated part is 0, the porosity of the functional area is 30%, and the pore size of the functional area is designed to be 6um, Circular holes, evenly distributed, obtain the three-dimensional model of the preform; ② According to the characteristics of the laser selective melting process, the three-dimensional model of the preform ...

Embodiment 3

[0056] In this embodiment, a molybdenum-copper electrode preform is prepared by a method for forming a complex preform of metal sweating material:

[0057] (1) Selection and processing of raw materials; ① Determine the high melting point molybdenum as the preform material, and the low melting point copper as the infiltration material; ② Coat a layer of copper with a thickness of 3um on the spherical surface.

[0058] (2) Structural design and processing of prefabricated parts; ①According to the target composite material component ratio and performance requirements, determine the porosity of the prefabricated part to be 40%, and design the pore size of 15um, circular holes, and uniform distribution to obtain a three-dimensional model of the prefabricated part ;2 Process the three-dimensional model of the prefabricated part according to the characteristics of the laser selective melting process, and output the process model.

[0059] (3) Preparation before the preform is formed;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com