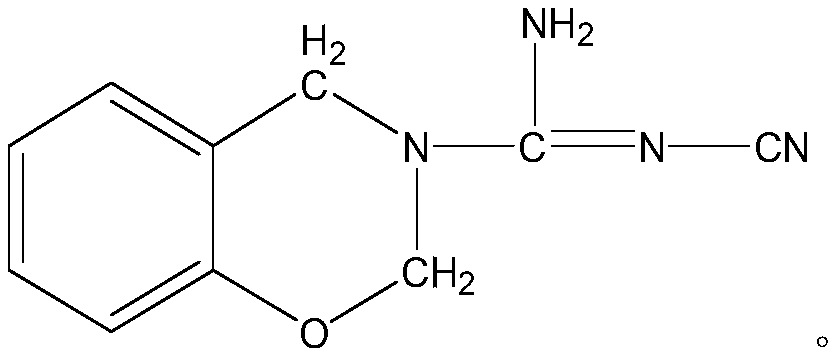

A latent curing agent for epoxy resin containing oxazine ring structure, its preparation method and application

A latent curing agent, epoxy resin technology, applied in organic chemistry and other directions, can solve problems such as poor compatibility between dicyandiamide and epoxy resin, and achieve the effects of reducing volatility, improving thermal stability and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

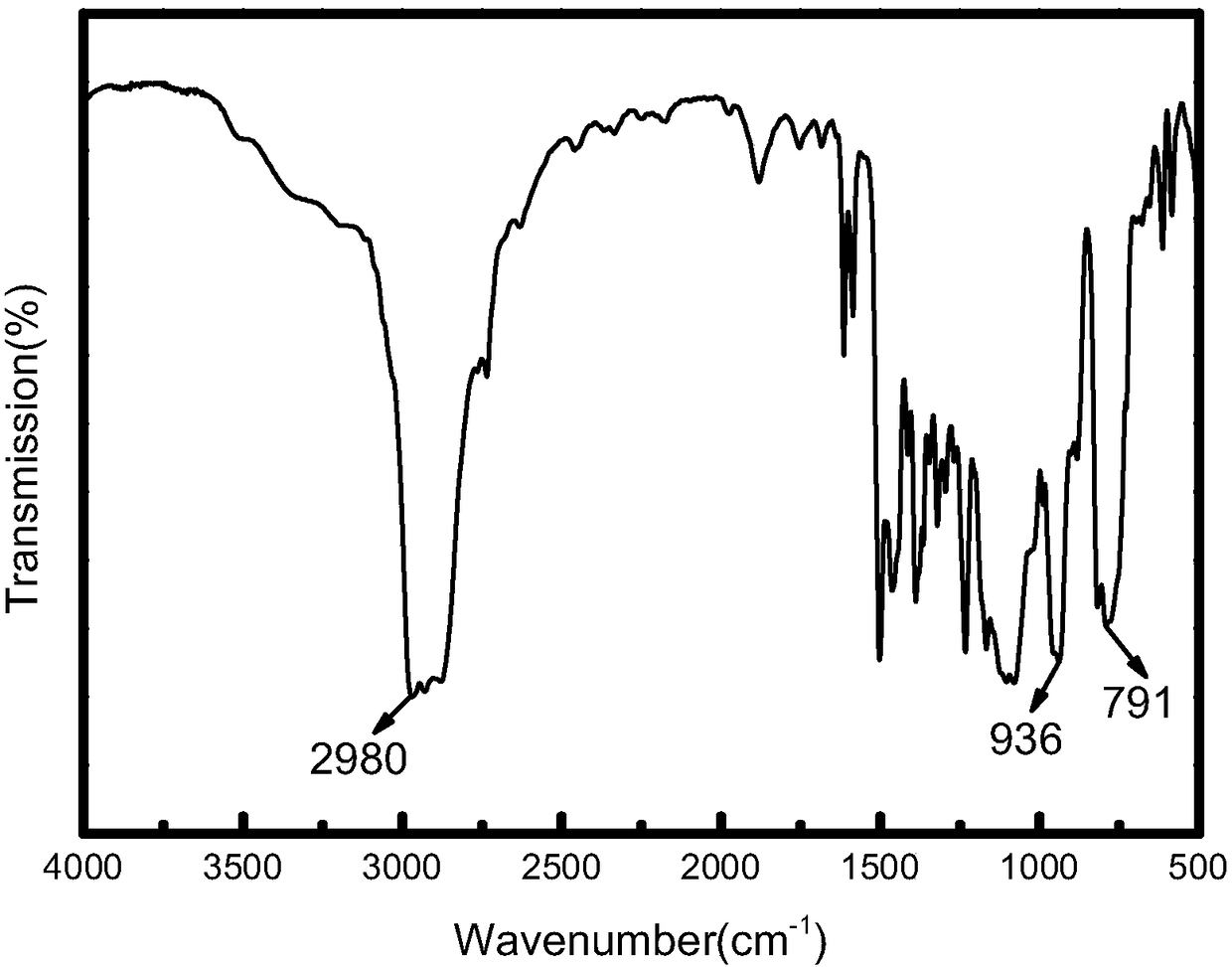

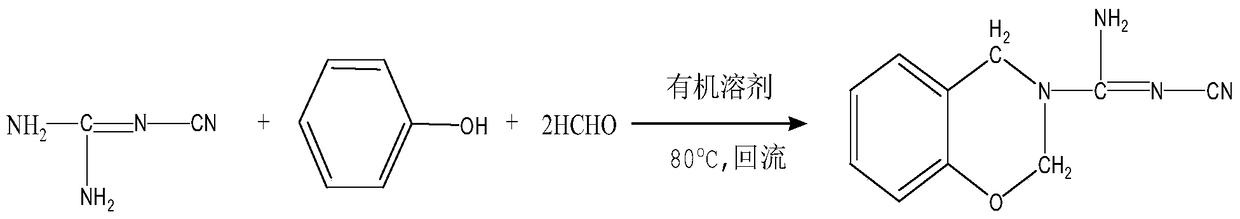

[0027] 1. Preparation of latent curing agent for epoxy resin

[0028] Weigh 30g (1mol) of paraformaldehyde and 42g (0.5mol) of dicyandiamide into a three-necked flask, then add absolute ethanol, add 47g (0.5mol) of phenol into the flask while stirring, slowly raise the temperature to 80°C, first Use 26% ammonia water to adjust the pH value to 8-9, stir and reflux for 3 hours, then adjust the pH value to 4-5 with 1mol / L hydrochloric acid solution, stir and reflux for 3 hours to obtain a transparent solution, and remove it by rotary evaporation at 80°C solvent and water to obtain the target product.

[0029] 2. Curing

[0030] Blend the epoxy resin (E44) with the latent curing agent prepared in step 1 according to the mass ratio of 1:0.2, stir evenly, let it stand and stand to remove the gas mixed during stirring, place the blended material in a ceramic crucible, and then The ceramic crucible was placed in an electric blast drying oven, and the curing procedure was as follows:...

Embodiment 2

[0032] 1. Preparation of latent curing agent for epoxy resin

[0033] Weigh 81g of formaldehyde solution with a concentration of 37% and 42g (0.5mol) of dicyandiamide into a three-necked flask, then pour into absolute ethanol, add 47g (0.5mol) of phenol to the flask under stirring, and slowly heat up to 80°C , first adjust the pH value to 8-9 with 26% ammonia water, stir and reflux for 3 hours, then adjust the pH to 4-5 with 1mol / L hydrochloric acid solution, stir and reflux for 3 hours to obtain a transparent solution, 80 ° C The solvent and water were removed by rotary evaporation to obtain the target product.

[0034] 2. Curing

[0035] Blend the epoxy resin (E44) with the latent curing agent prepared in step 1 according to the mass ratio of 1:0.25, stir evenly, let it stand and stand to remove the gas mixed during stirring, place the blended material in a ceramic crucible, and then The ceramic crucible was placed in an electric blast drying oven, and the curing procedure...

Embodiment 3

[0037] 1. Preparation of latent curing agent for epoxy resin

[0038] Weigh 30g (1mol) of paraformaldehyde and 42g (0.5mol) of dicyandiamide into a three-necked flask, then pour into absolute ethanol, add 47g (0.5mol) of phenol into the flask while stirring, and slowly heat up to 80°C. First adjust the pH value to 8-9 with ammonia water with a mass fraction of 26%, stir and reflux for 3 hours, then adjust the pH value to 4-5 with 1mol / L hydrochloric acid solution, and stir and reflux for 3 hours to obtain a transparent solution. The solvent and water were distilled off to obtain the target product.

[0039] 2. Curing

[0040] Blend the epoxy resin (E44) with the latent curing agent prepared in step 1 according to the mass ratio of 1:0.3, stir evenly, let stand and stand to remove the gas mixed during stirring, place the blended material in a ceramic crucible, and then The ceramic crucible was placed in an electric blast drying oven, and the curing procedure was as follows: h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com