Konjac flying powder epoxy curing agent and preparation method and floor coating containing the curing agent

A technology of epoxy curing agent and konjac flying powder, which is applied in the field of polymer chemistry, can solve environmental pollution and other problems, and achieve the effects of easy-to-obtain raw materials, excellent wear resistance, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of konjac flying powder epoxy curing agent, its preparation method is as follows: take konjac flying powder 10g and phenol 10g and join in the three-necked flask that stirrer and reflux condenser are housed, oil bath is preheated to setting temperature 150 ℃, Slowly add 0.4 g of mixed acid catalyst (75% sulfuric acid, 15% phosphoric acid, 10% oxalic acid) dropwise, cool to room temperature after reacting for 1 h, wash the reactant with methanol, filter, and remove methanol under reduced pressure to obtain the liquefied product of konjac flying powder. Add 10.0 g of the liquefied product of konjac flying powder to a four-necked flask equipped with electric stirring, condenser, thermometer and dropping funnel, and add 11.0 g of diethylenetriamine dropwise while stirring at 60 ° C, until the reaction system dissolves completely at 70 Slowly add 3.2g of formaldehyde dropwise at ℃. After the dropwise addition, raise the temperature to 80℃ for 2 hours, and then keep it ...

Embodiment 2

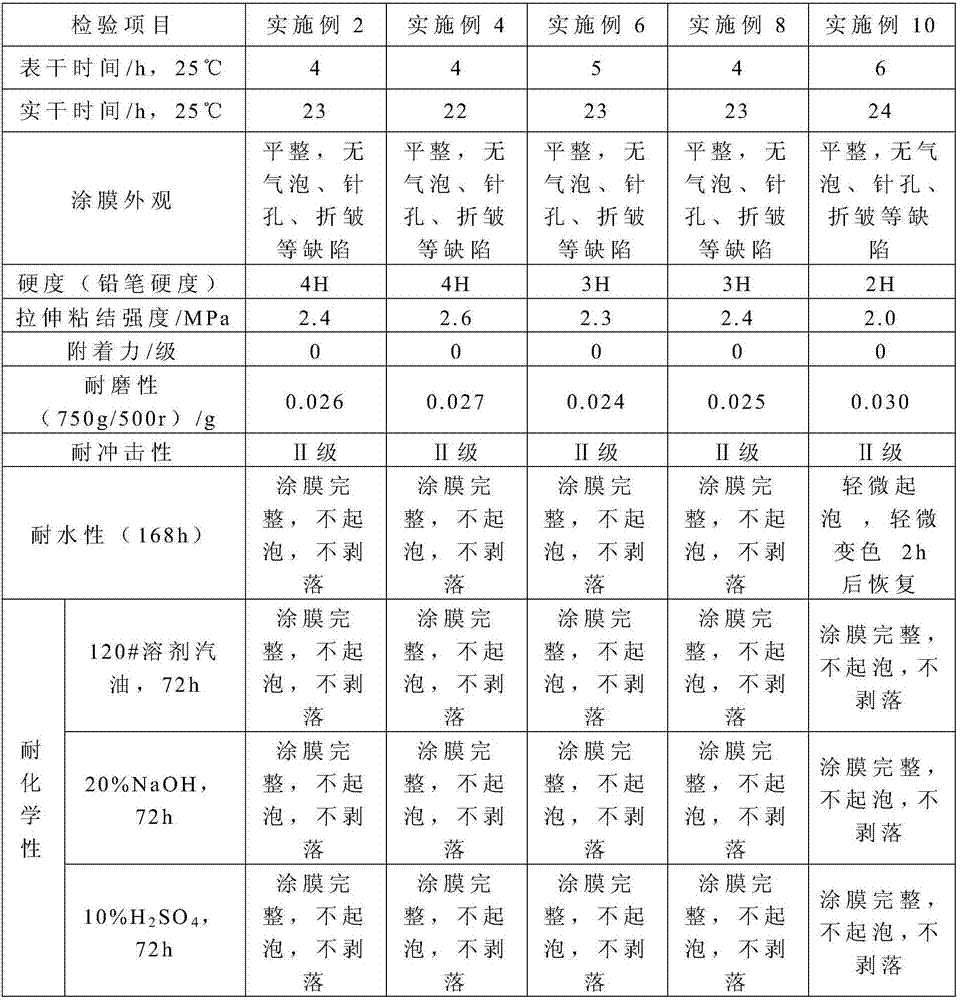

[0026] Add 1000g of epoxy resin E-51, 130g of epoxy diluent cardanol-based glycidyl ether into the disperser, after the resin is evenly dispersed, add 2g of leveling agent TEGO Glide B 1484, 3g of defoamer TEGO Airex900, and then Disperse evenly, add 1000g of quartz powder to disperse evenly at high speed, and then sand-mill to 80 mesh with a sand mill to obtain the A component of the floor coating. Take by weighing the konjac flying powder epoxy curing agent 300g prepared by the method in embodiment 1 as the B component of floor paint. Before painting, stir and mix components A and B evenly before construction. The construction process of the floor coating is as follows: base treatment → primer coating → putty → polishing → surface coating → anti-slip treatment. According to GB / T 22374-2008, the performance of floor coatings is determined. The surface of the solvent-free floor coatings is smooth and beautiful, with good wear resistance, pressure resistance, impact resistance...

Embodiment 3

[0028] A kind of konjac flying powder epoxy curing agent, its preparation method is as follows: take konjac flying powder 10g and nonylphenol 10g and join in the three-necked flask that agitator and reflux condenser are housed, oil bath is preheated to setting temperature 120℃ 0.2 g of mixed acid catalyst (80% sulfuric acid, 15% phosphoric acid, 5% oxalic acid) was slowly added dropwise, cooled to room temperature after 2 hours of reaction, the reactant was washed with methanol, filtered, and the methanol was removed under reduced pressure to obtain the liquefied product of konjac flying powder. Add 10.0g of konjac flying powder liquefied product to a four-necked flask equipped with electric stirring, condenser, thermometer and dropping funnel, and add 6.4g m-xylylenediamine dropwise while stirring at 50°C until the reaction system dissolves completely in Slowly add 1.6g of formaldehyde dropwise at 70°C. After the dropwise addition, raise the temperature to 80°C for 3 hours, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com