Prefabricated radiant heating system

A technology of radiant heating and heating device, which is applied in hot water central heating system, heating system, household heating and other directions, can solve the problem of low outlet water temperature, improve the temperature of supply and return water, achieve quick effect and good economy Effect

Inactive Publication Date: 2011-06-15

姚善新

View PDF4 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the heating season, the outlet water temperature of the cooling water tower is lower than 30°C, so it cannot be directly used for heating of many buildings

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

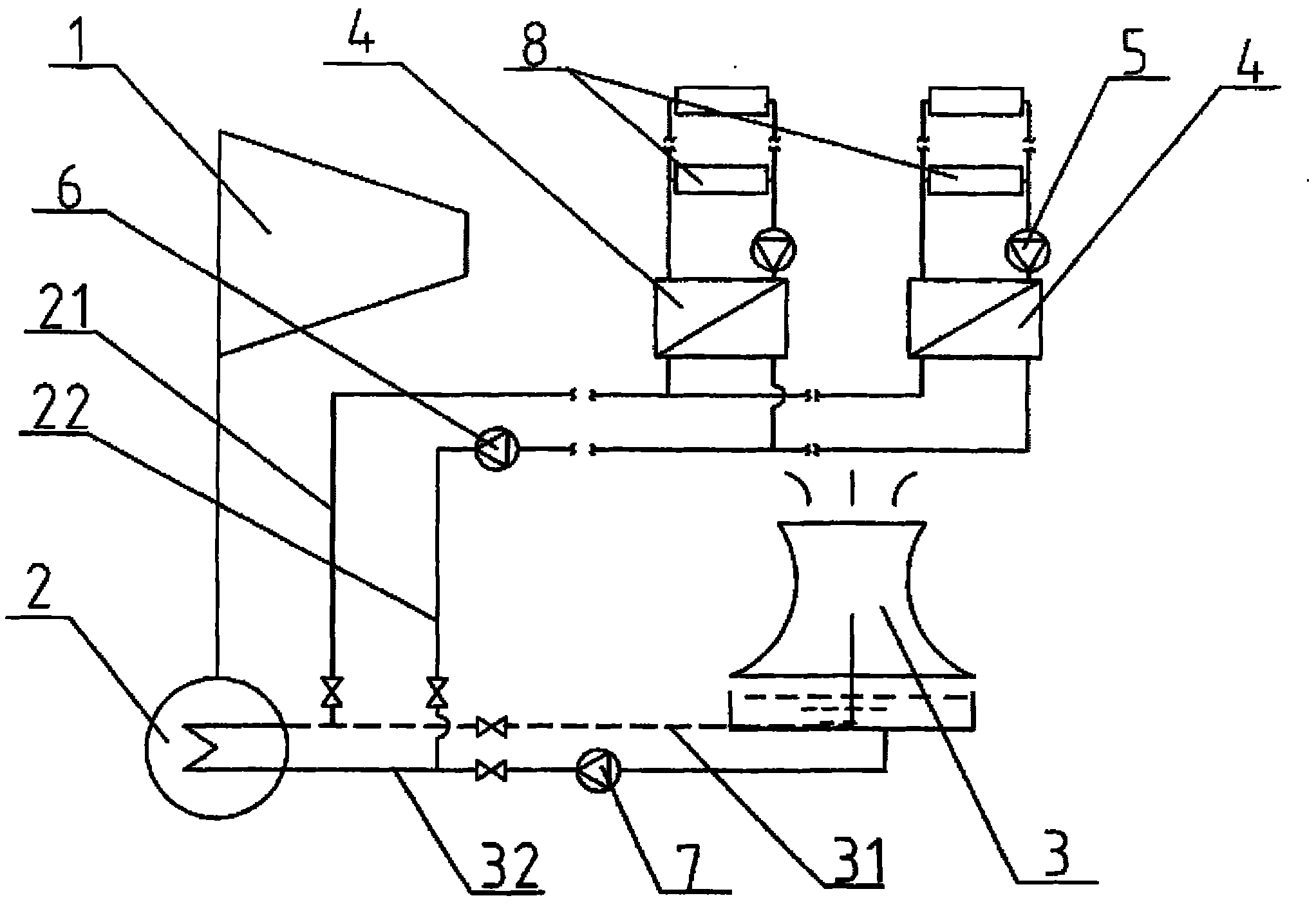

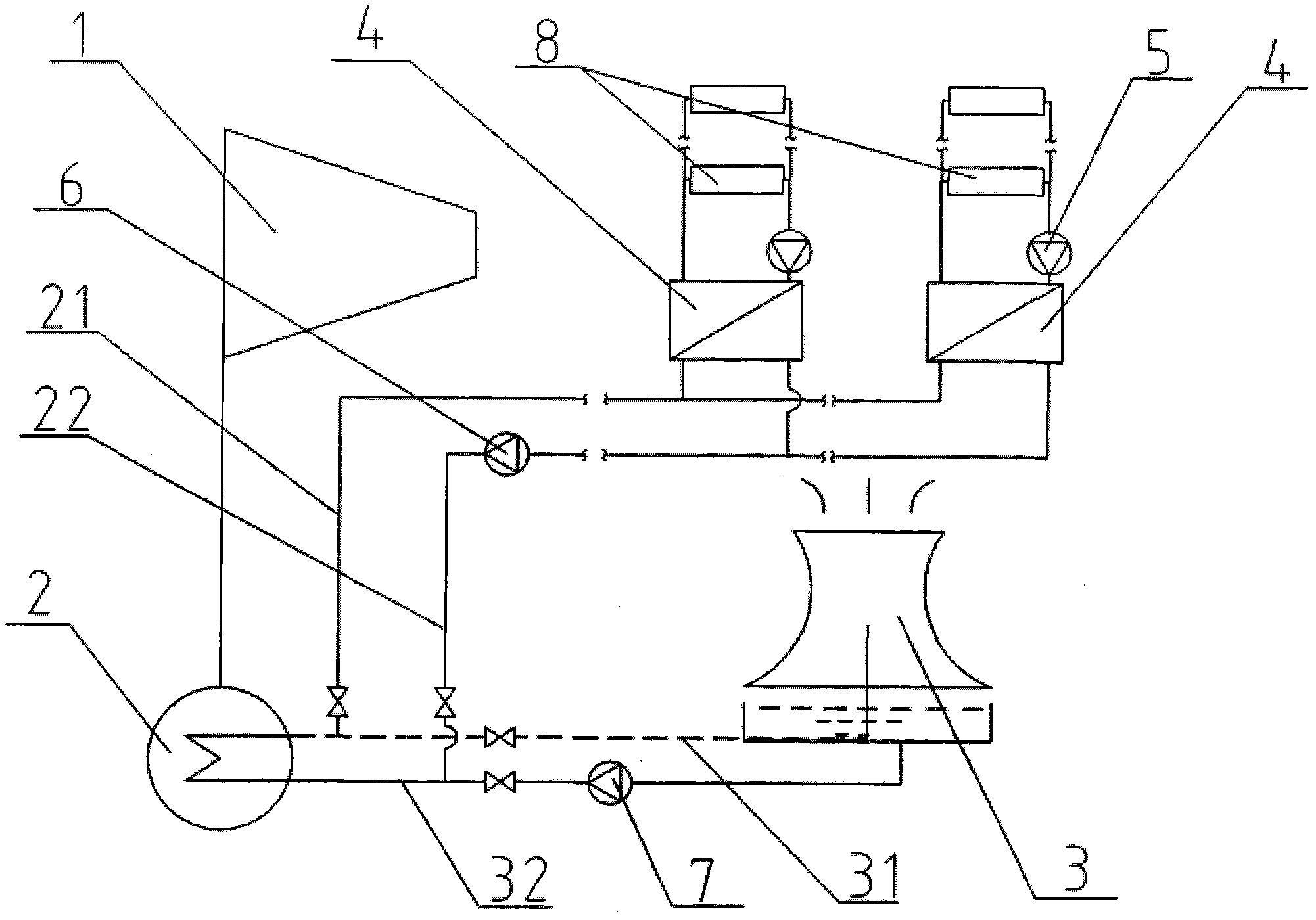

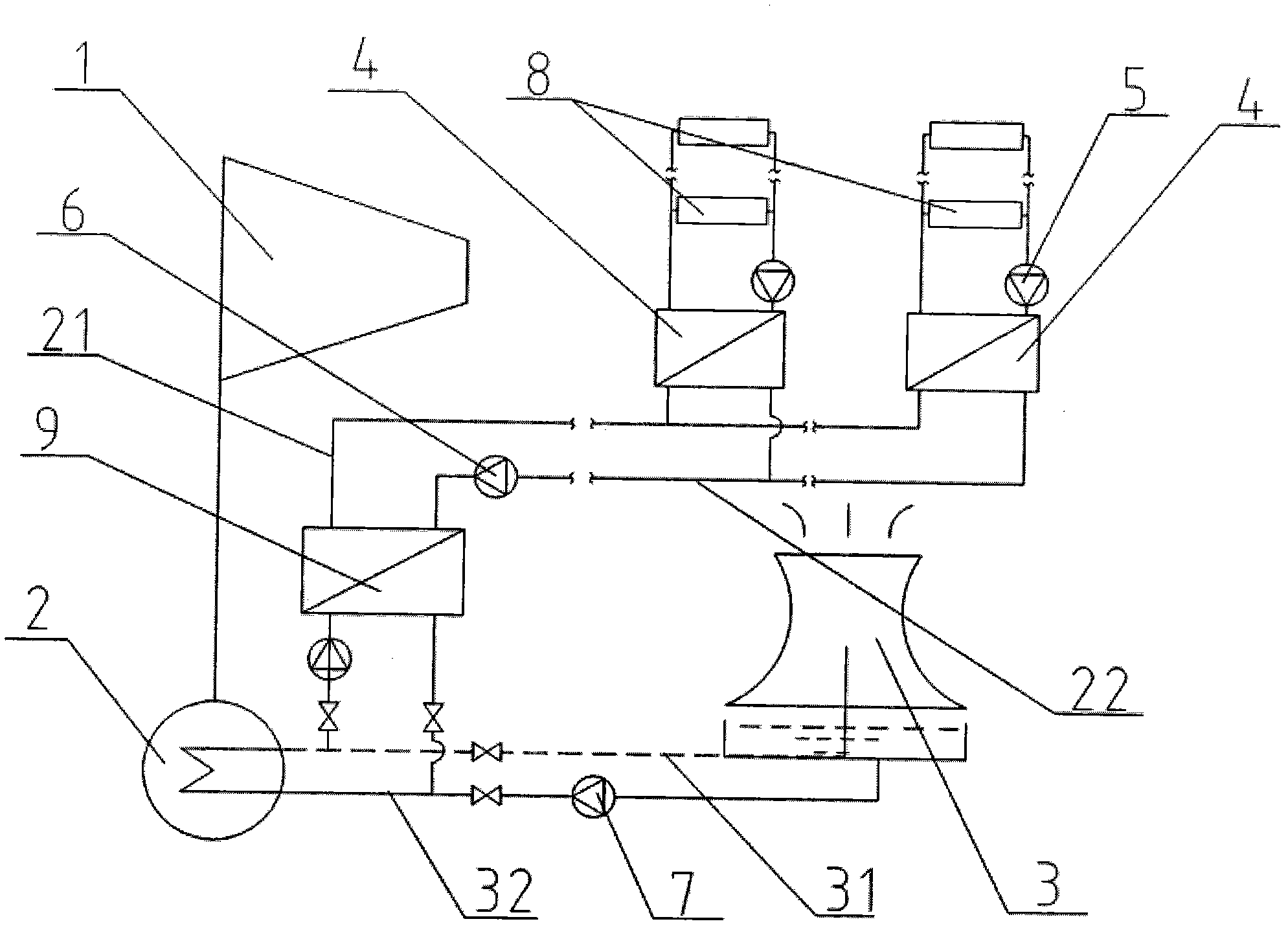

The invention relates to a prefabricated radiant heating system comprising a steam turbine, a condenser, a water cooling tower, a plate-type heat exchanger, a user circulating pump, a heat supply network circulating pump and a cooling water pump, wherein one end of the condenser is connected with the steam turbine and obtains circulating cooling water with increased temperature, and the other end is respectively connected with the plate-type heat exchanger and the water cooling tower; a part of the circulating cooling water carry out heat exchange with the plate-type heat exchanger to supply heating to users, and the other part of the circulating cooling water enters the water cooling tower for cooling; the user circulating pump is matched with the plate-type heat exchanger; the cooling water pump is arranged between the water cooling tower and the condenser, and cooling water flows back into the condenser. The prefabricated radiant heating system has multiple advantages of low improvement expense without improving the traditional steam turbine and condenser, short engineering period, good economy, quick effect, high heat energy utilization ratio, and the like.

Description

Prefabricated radiant heating system 【Technical Field】 The invention relates to a heating system, in particular to a prefabricated radiant heating system using circulating cooling water of a thermal power plant as a heat source. 【Background technique】 With the development of society and the continuous improvement of people's living standards, the scale of buildings continues to increase, and the energy consumption of buildings is also increasing. At the same time, the primary energy is increasingly depleted, and the contradiction between energy supply and demand has become increasingly prominent. In order to sustain development, the country is paying more and more attention to energy conservation and emission reduction. Electricity is an indispensable advanced energy source in today's society, but the power generation efficiency of thermal power plants is only about 40%, and nearly 50% of the heat is mainly discharged to the atmosphere or water bodies through cooling water. I...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F24D3/02F24D19/00

Inventor 姚善新姚洋

Owner 姚善新

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com