Method for making and applying micro-porosity standard diagram of cast detected by fluorescence permeation

A technology of microscopic porosity and standard map, which is applied in the production and application of standard maps, can solve the problems that the precision of non-destructive testing cannot be guaranteed, and the size and grade of microporosity of castings cannot be accurately determined.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

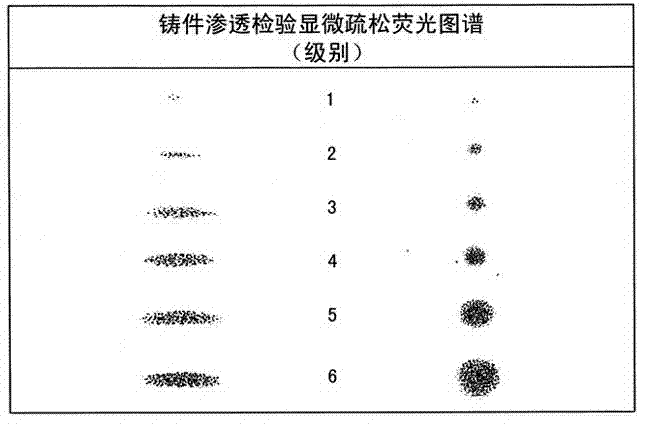

[0028] The preparation and application method of the standard atlas for fluorescent penetrant inspection casting microporosity of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0029] The preparation method of the standard atlas of fluorescence penetrant inspection casting microporosity of the present invention comprises the following steps successively:

[0030] Step 1. Collect microporous samples of cast parts

[0031] Under the microscope, observe the physical metallography of cast parts, collect samples with different degrees of porosity through processing, grinding, corrosion, and metallographic inspection, and classify them;

[0032] Step 2. Fluorescence penetrant test on the sample

[0033] Fluorescence penetrant inspection shall be carried out on samples whose microscopic porosity level is determined by physical metallographic method, and photographs shall be taken of the fluorescence display, which sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com