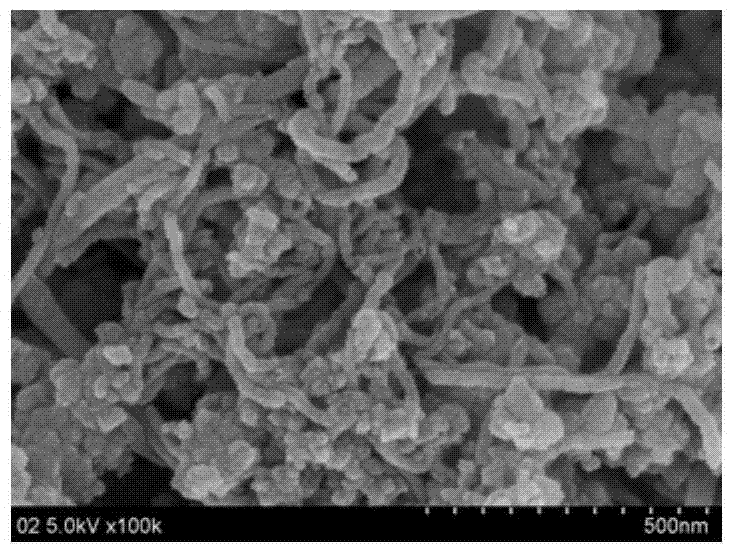

In situ interfacial polymerization method of a fiber-based conductive polypyrrole/carbon nanotube composite electrode material

A carbon nanotube composite and electrode material technology, which is applied in the manufacture of hybrid capacitor electrodes, electrolytic capacitors, hybrid/electric double layer capacitors, etc., to achieve the effects of simple preparation method, high specific capacitance and shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

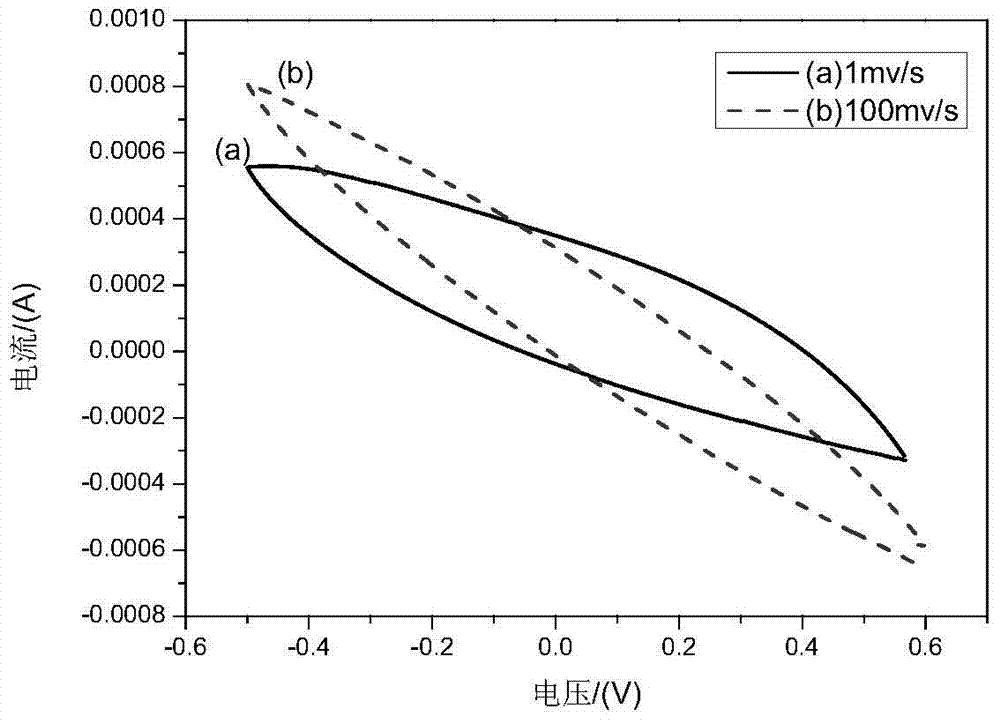

[0030] Prepare a 0.5mol / L ferric chloride aqueous solution containing 0.005mol / L cetyltrimethylammonium bromide, then add carbon nanotubes 5mg / ml, and form an aqueous dispersion A after ultrasonic treatment for 20min; the cotton fabric Immerse in the water phase dispersion A, control the bath ratio of the fabric to the water phase volume at 1:50, shake for 10 minutes, then add 0.4mol / L pyrrole in chloroform solution B dropwise, the dropping speed is controlled at 50-60d / min, drop After the addition is complete, place the mixed solution in an ice-water bath (0°C) and oscillate and stir for 120 minutes; after the reaction, take out the sample, soak it in 0.1mol / L sulfuric acid solution for 30 minutes, then soak it in acetone for 10 minutes, and wash it with deionized water. Dry under vacuum.

Embodiment 2

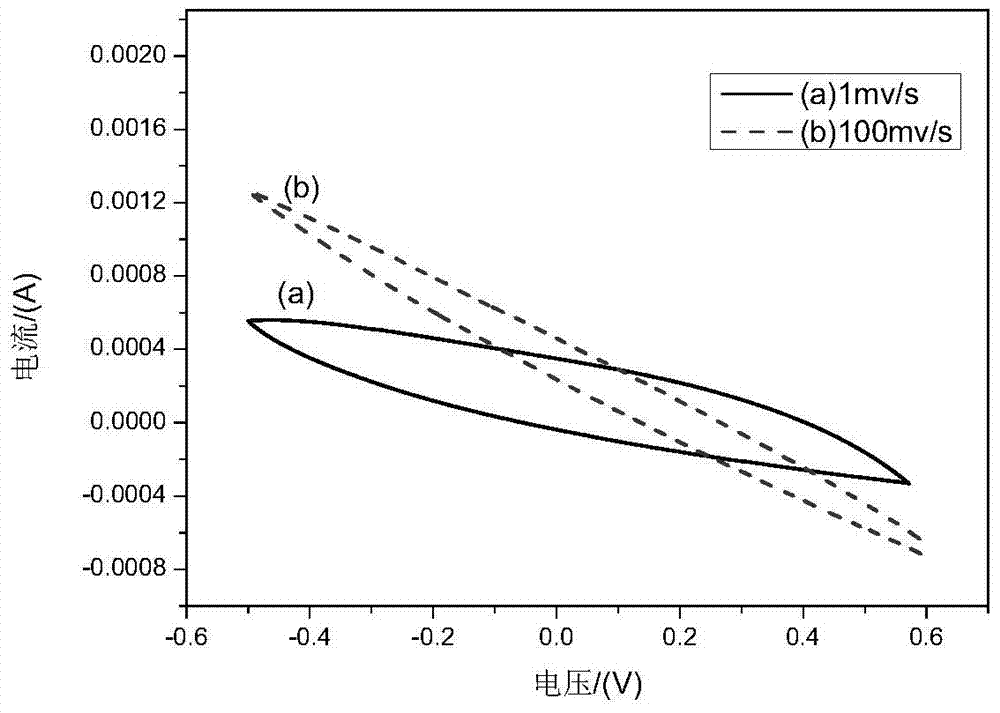

[0032] Prepare a 0.6mol / L ferric chloride aqueous solution containing 0.004mol / L dodecyltrimethylammonium bromide and 0.006mol / L Tween 80, add carbon nanotubes 6mg / ml, and form water after ultrasonic treatment for 30min phase dispersion A; immerse the viscose fabric in the aqueous phase dispersion A, the bath ratio of the fabric and the water phase volume is controlled at 1:50, shake for 10 minutes, then add 0.4mol / L pyrrole in chloroform solution B dropwise, the dropping speed Control at 50-60d / min. After the dropwise addition, place the mixed solution in an ice-water bath (0°C) and shake and stir to continue the reaction for 100 minutes; after the reaction, the sample is taken out, soaked in 0.1mol / L hydrochloric acid solution for 40 minutes, and then placed in acetone Soak for 10min, wash with deionized water and dry under vacuum condition.

Embodiment 3

[0034] Prepare a 0.7mol / L ferric chloride aqueous solution containing 0.005mol / L cetyltrimethylammonium bromide and 0.005mol / L Tween 80, add carbon nanotubes 6mg / ml, and form water after ultrasonic treatment for 30min phase dispersion A; soak the cotton fabric in the aqueous phase dispersion A, control the bath ratio of fabric and water phase volume at 1:60, vibrate for 20min, then add 0.5mol / L pyrrole in chloroform or bromoform solution B dropwise, The dropping speed is controlled at 50-60d / min. After the dropping is completed, place the mixed solution in an ice-water bath (0°C) and shake and stir to continue the reaction for 100 minutes; Soak in acetone for 5 min, wash with deionized water and dry under vacuum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com