A kind of aminated self-porous polymer adsorbent and its application

A microporous polymer and adsorbent technology, applied in the direction of adsorption of water/sewage treatment, water pollutants, and other chemical processes, can solve the problems of pathogenicity and biological carcinogenicity, achieve large adsorption capacity, improve adsorption capacity, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

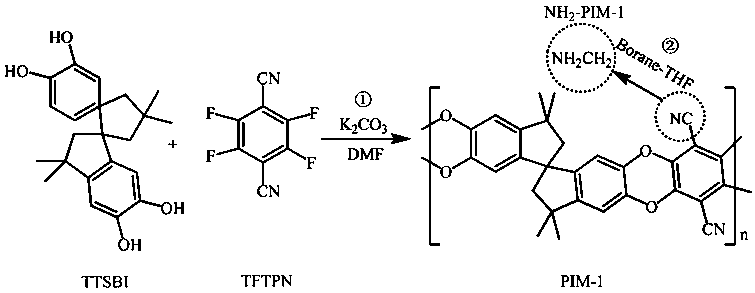

[0016] Example 1 Preparation of aminated self-microporous polymer adsorbent

[0017] (1) Synthesis of self-owned microporous polymer PIM-1: Dissolve 5.1062 g (15 mmol) TTSBI and 3.0013 g (15 mmol) TFTPN in 100 mL DMF, bubbling in nitrogen, and magnetically stirring at 65 ℃ until completely dissolved After adding 5.1248 g anhydrous K 2 CO 3 Under the protection of nitrogen, the reaction was continued with magnetic stirring at 65 ℃ for 72 h; after the reaction was completed, cooled to room temperature, the reaction solution was poured into 150 mL of deionized water, and filtered to obtain a filter cake; then in a 500 mL beaker, the resulting filter cake Stir magnetically in 350 mL of deionized water for 15 min, and then filter with suction. The filter cake was dried at 110 ℃ for 12 h with air blowing, followed by 300 mL of 1,4-dioxane, 100 mL of acetone, and 200 mL of deionized water. Wash with 100 mL of acetone, filter with suction, and finally blast dry at 110°C for 12 h, for lat...

Embodiment 2

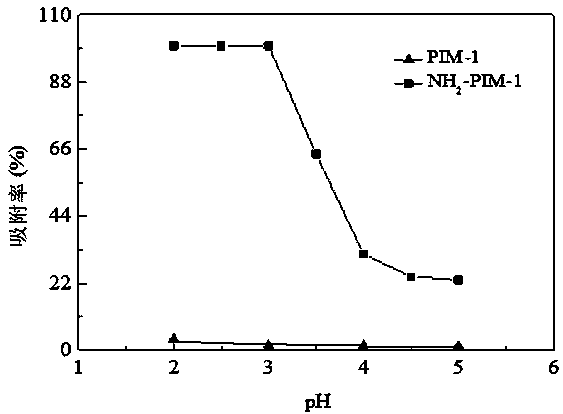

[0020] Example 2 The influence of pH value on the adsorption performance of aminated microporous polymer adsorbent

[0021] Using the NH obtained in Example 1 2 -PIM-1 and non-aminated PIM-1 were subjected to static adsorption tests on sunset yellow in solutions of different pH values, and the absorption rate was measured by ultraviolet spectrophotometry, the results are as follows figure 2 Shown. Concentration of initial sunset yellow: 100 ppm; amount of adsorbent: 5 mg; shaking time: 2 h; temperature: 25°C; sample volume: 10 mL.

[0022] by figure 2 It can be seen that compared with PIM-1, NH under different pH values 2 -PIM-1 has good adsorption performance for sunset yellow.

Embodiment 3

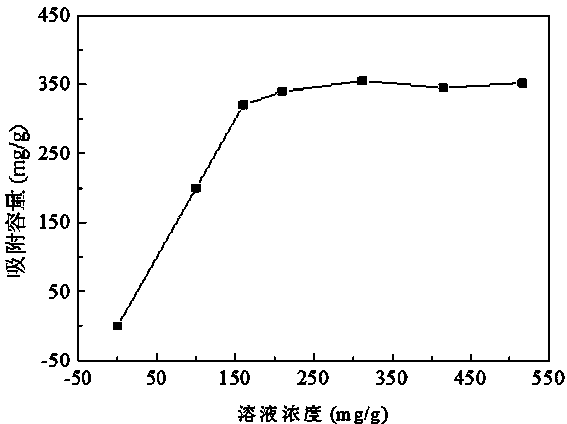

[0023] Example 3 Measurement of saturated adsorption capacity

[0024] The results of the determination of the adsorption effect of the aminated self-microporous polymer adsorbent on different concentrations of sunset yellow image 3 .

[0025] by image 3 It can be seen that when the sunset yellow solution is at a lower concentration, the adsorption capacity of the aminated self-microporous polymer adsorbent for sunset yellow increases with the increase of its concentration. When the initial concentration reaches 150mg / g, a plateau appears, indicating that the adsorbent When the saturated state is reached, the saturated adsorption capacity of the aminated self-microporous polymer adsorbent for sunset yellow is 348.16 mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com