Pedal electric heating fire box using heating wires

An electric heating wire and electric heating technology, applied in electric heating systems, household heating, heating methods, etc., can solve the problems of large thermal stress deformation, high manufacturing cost, reduced insulation performance, etc., achieve uniform thermal stress deformation, and eliminate temperature unevenness. , The effect of small thermal stress deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

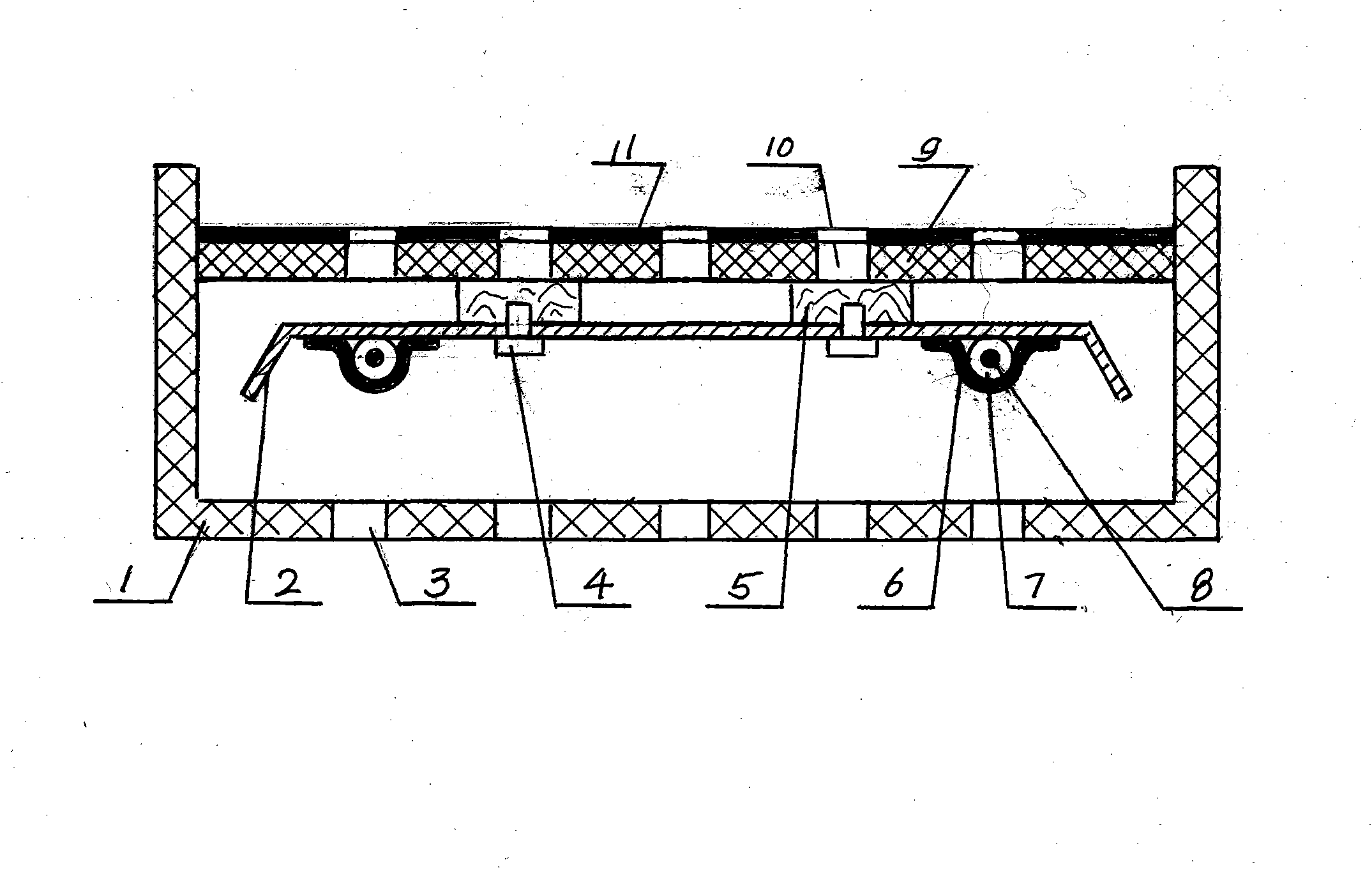

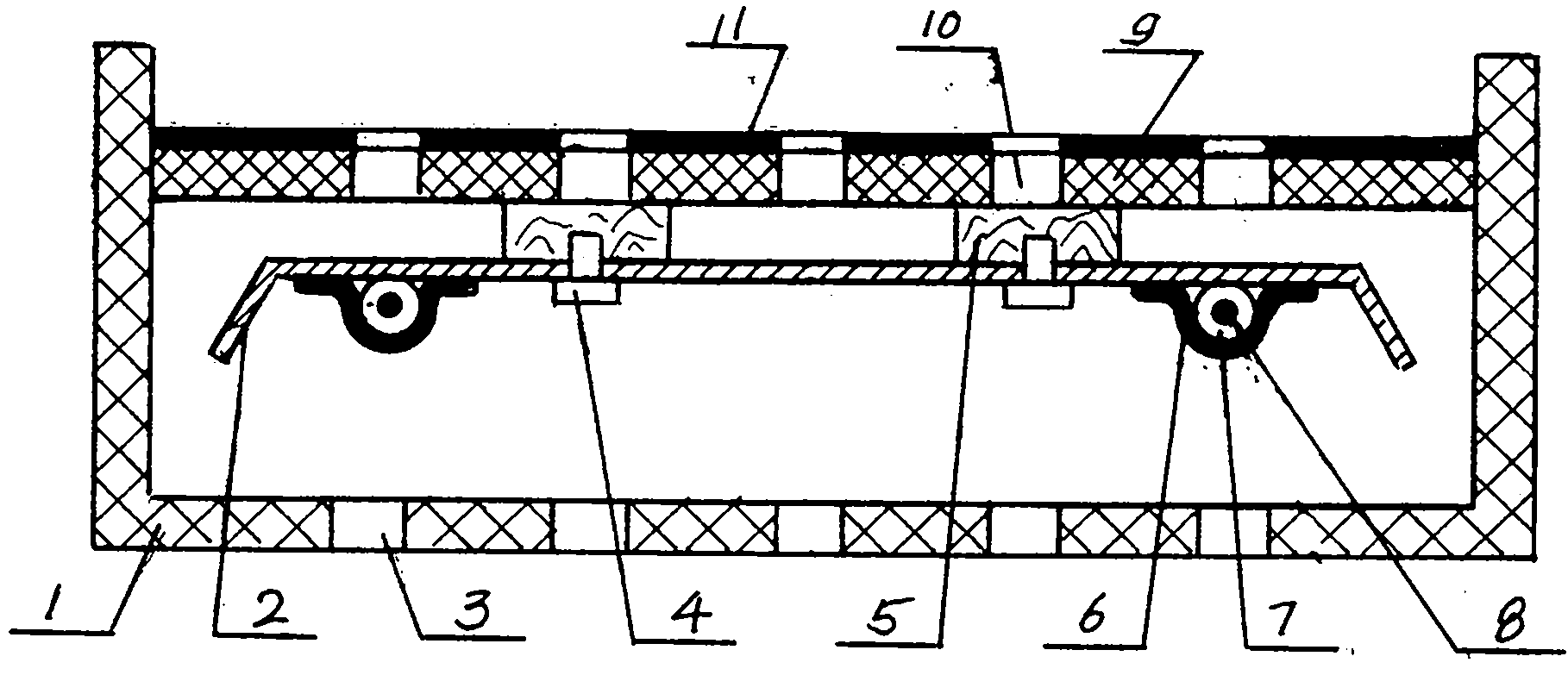

[0019] As shown in the figure, the box body 1 includes a closed peripheral wall and a bottom plate installed at its lower end, on the bottom plate is provided with bottom plate ventilation holes 3, on the box body 1, a support rod 5 is installed, and the support rod 5 is made of insulating material , a tread plate 9 made of a good conductor of heat is provided on the support rod 5, a tread plate ventilation hole 10 is provided on the tread plate 9, an electrostatic flocking cushion layer 11 is provided on the tread plate 9, and an electrostatic flocking cushion layer 11 is provided on the tread plate 9. 5. The heat conduction plate 2 is installed on the bottom through the fastening screw 4. The distance between the lower surface of the support rod 5 and the upper surface of the heat conduction plate 2 is designed to be 20MM. The heat conduction plate 2 is made of a good conductor of heat. On the surface, there is an electric heating device installed in close contact with sticke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com