Storage battery insulating support plate

A battery and supporting plate technology, applied in the direction of battery components, circuits, electrical components, etc., can solve the problems of inconvenient battery installation and positioning, deformation of the battery case, and poor versatility of the isolation block, so as to eliminate the risk of electric shock and reduce the contact surface area. Increased, simple structure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

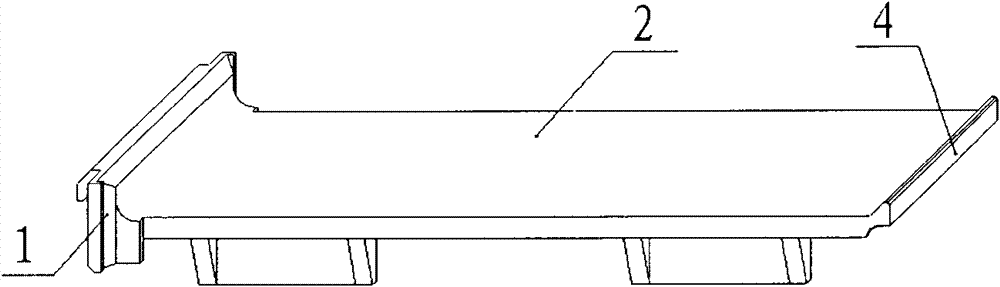

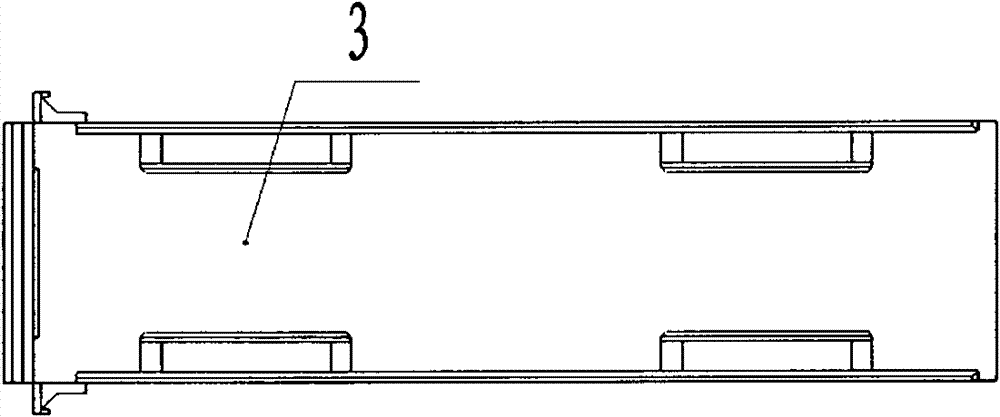

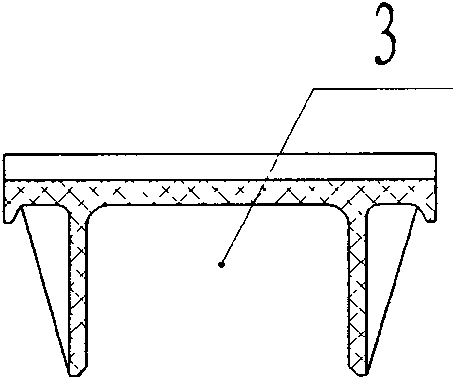

[0016] like figure 1 , 2 Shown in , 3: a storage battery insulating support plate 5, the overall structure is an insulating plastic integral body composed of four parts: an isolation block 1, an insulating expansion working surface 2, a mounting groove 3, and a limit block 4, and the upward part is an insulating The extended working surface 2, the front end of the insulating extended working surface 2 is an isolation block 1, the rear end is a limit block 4, and the back side of the insulating extended working surface 2 has a mounting groove 3, and the isolation block 1 of one of the battery insulation supporting plates 5 can be connected with The limit block structure of the other storage battery insulation supporting plate is connected in cooperation.

[0017] The area of the insulating extended working surface is larger than the area of the installation groove 3 .

[0018] The method of use is that after the battery rack is assembled, the battery insulating support pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com