Method and apparatus for solder ball placement

A solder ball and template technology, applied in the field of ball grid array, can solve the problem of insufficient accurate positioning of solder balls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

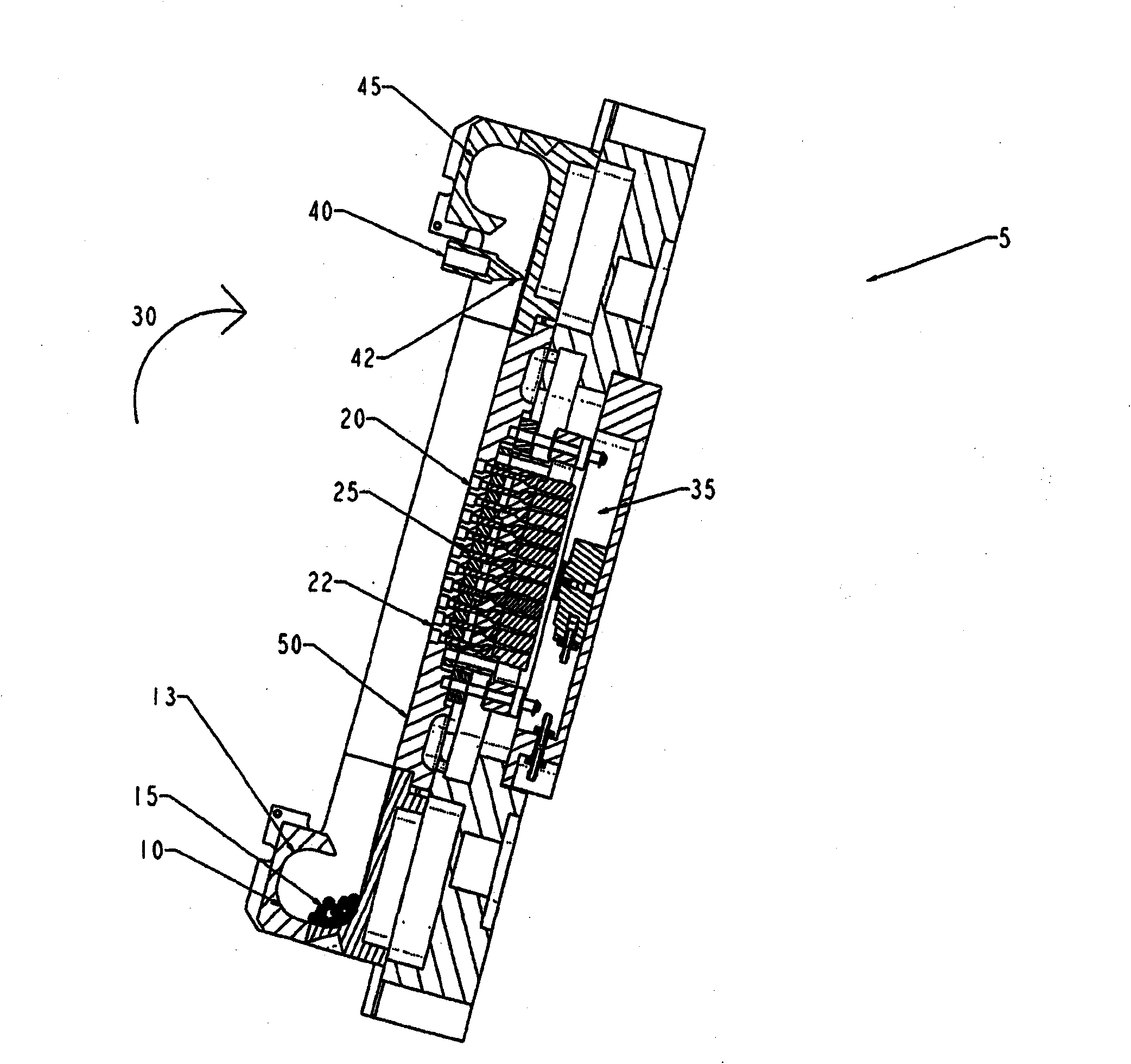

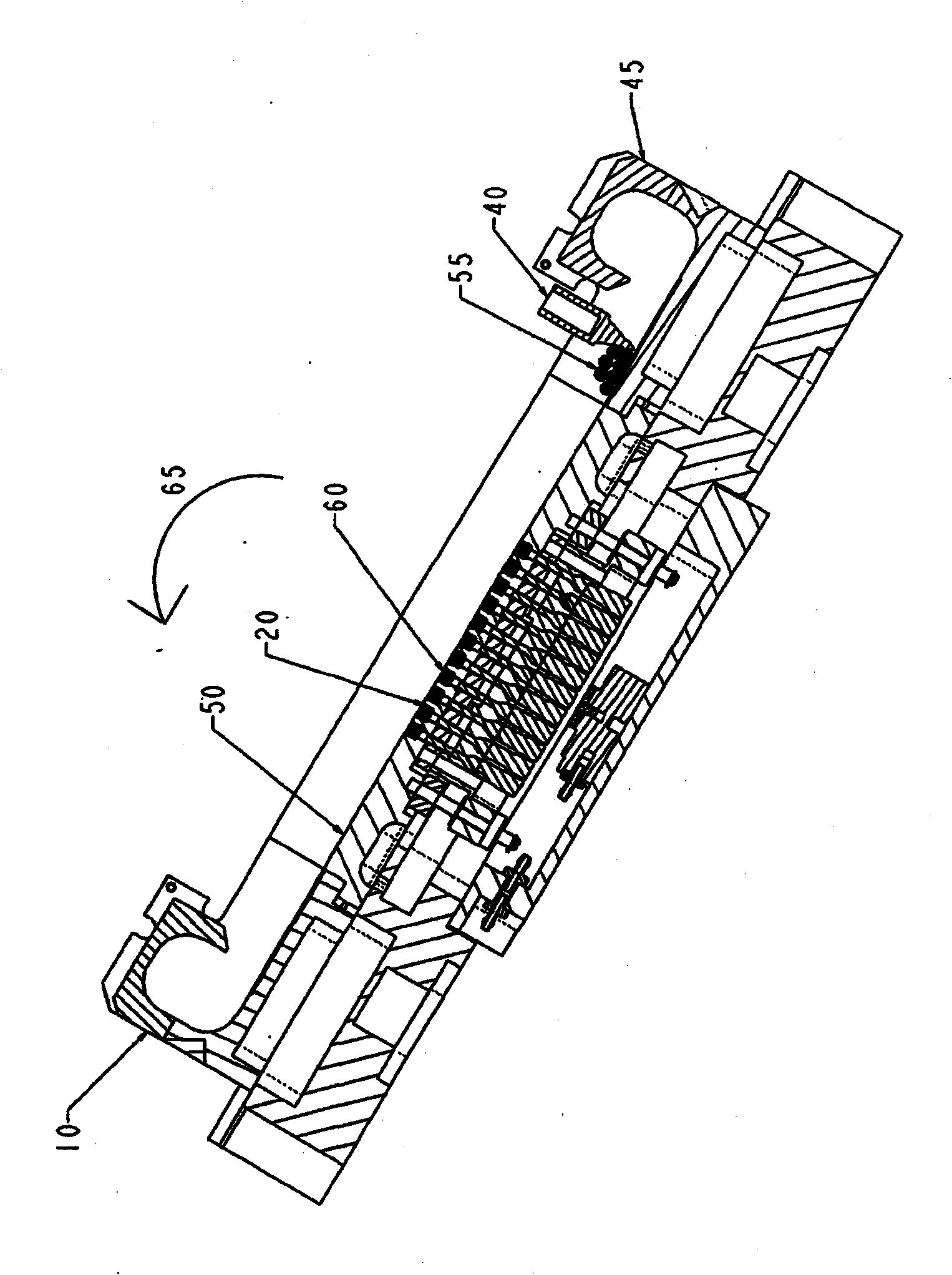

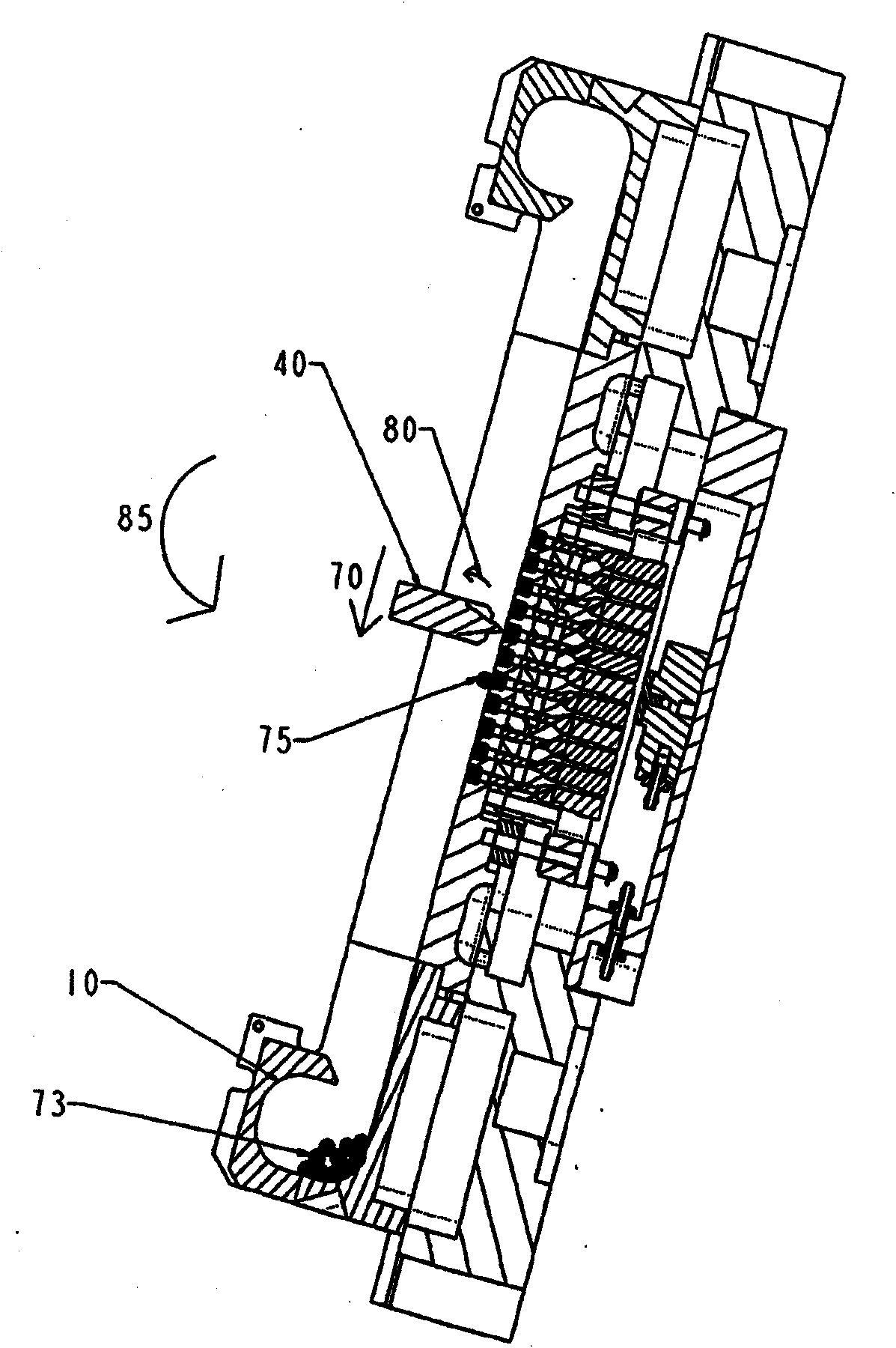

[0031] figure 1 The first stage of the method according to the invention is shown. At this stage, the solder ball mounting module 5 is in the first position ready to fill the recess 20 in the ball grid array template 22. In this first position, the solder ball 15 is located in the storage area, in this case the solder ball holding area 10. The holding area 10 is arranged such that the solder balls 15 are held in the holding area under varying angle conditions of the module 5 by the partially enclosed surface 13.

[0032] The module 5 includes a continuous surface 50 on which the solder balls 15 can flow to pass through the template 22. At the opposite end of the surface 50 is a second solder ball holding area 45 for receiving the solder balls as they flow through the template 22 and also collecting the solder balls. Therefore, within the rotation range of the module 5, the respective holding areas 10, 45 can hold the solder balls without flowing out of the module 5, but still ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com