Sludge scraper for clarifier

A mud scraper and clarifier technology, applied in chemical instruments and methods, settling tanks, feeding/discharging devices of settling tanks, etc., can solve the problems of large-scale clarifiers, low efficiency, and long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

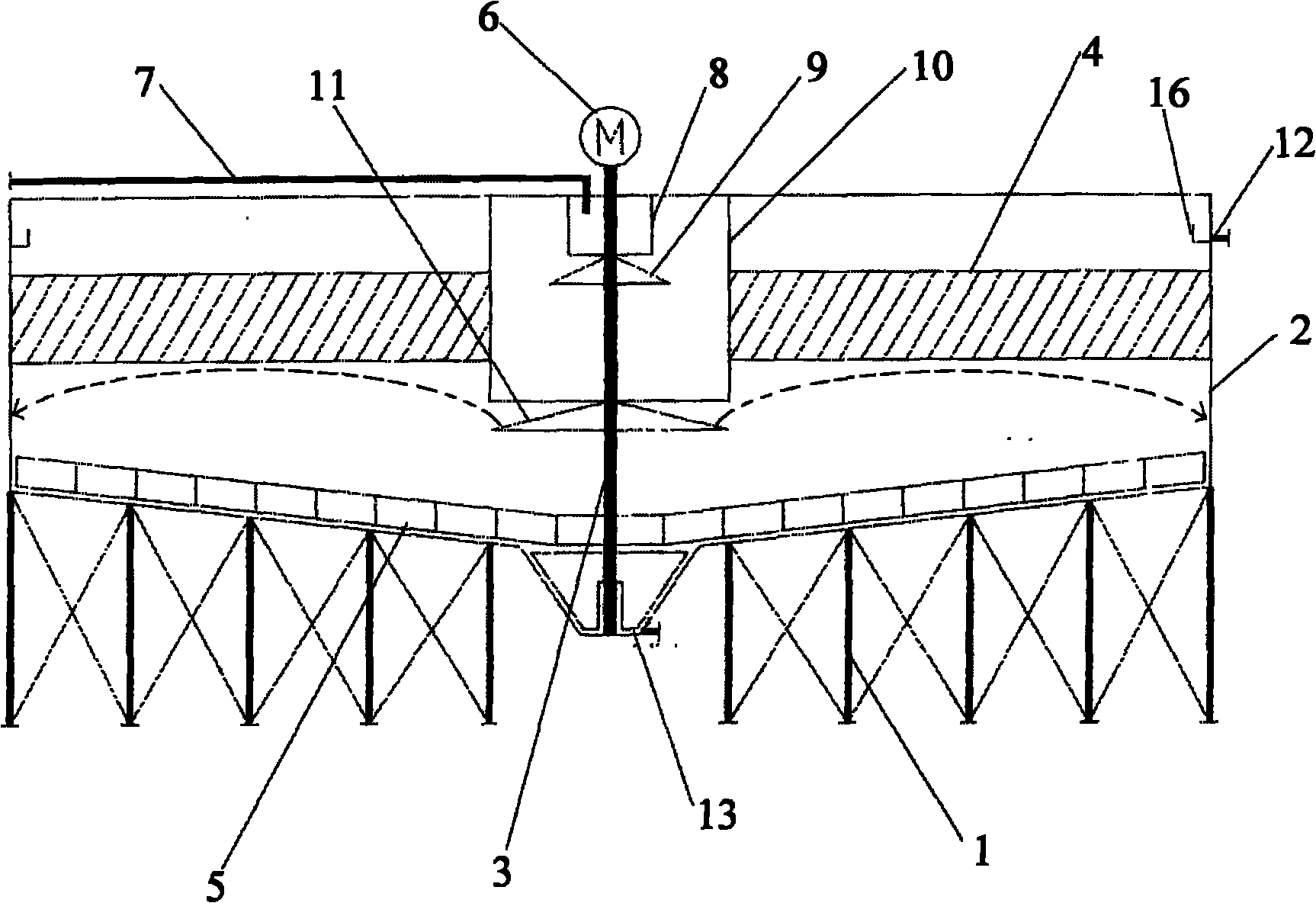

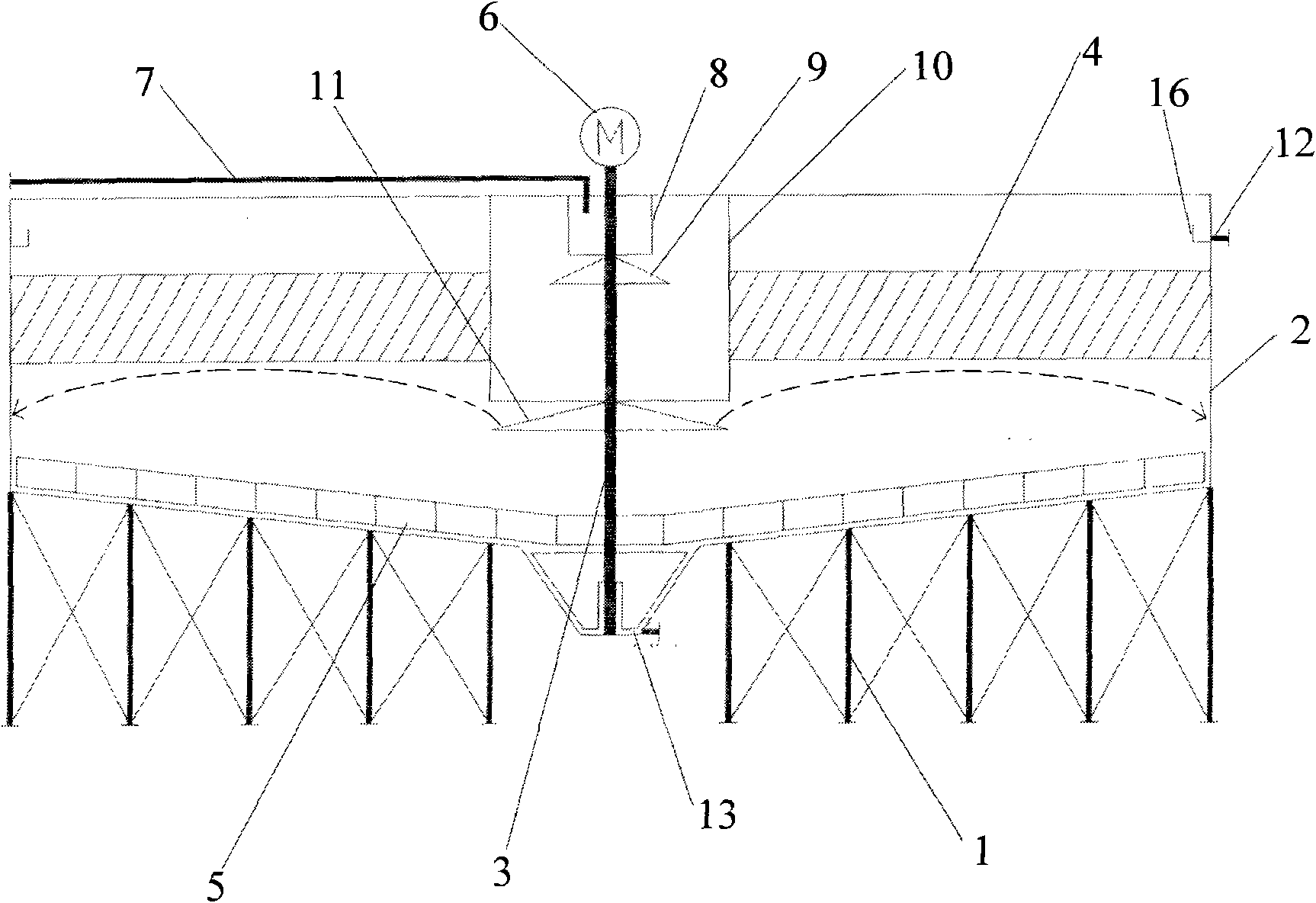

[0015] A clarifier mud scraper, which includes a bracket 1, a cylinder body 2, a diversion device, an inclined plate 4, a mud scraper and a gear motor 6; the diversion device, the inclined plate 4 and the mud scraper are all placed in the cylinder body 2 Inside; cylinder body 2 is installed on bracket 1; the top of cylinder body 2 is provided with gray water inlet 7; the diversion device is two-stage, and the diversion device includes diversion tube and reflection plate; the first-level reflection plate 9 is placed in a Below the first-stage guide tube 8; the first-stage guide tube 8 is placed under the gray water inlet 7 and communicated with the gray water inlet 7; the second-stage guide tube 10 is set on the first-stage guide tube 8 and the first-stage reflector 9 and the outside of the first-level guide tube 8; the second-level reflector 11 is placed below the second-level guide tube 10; the swash plate 4 is placed between the outside of the second-level guide tube 10 and t...

Embodiment 2

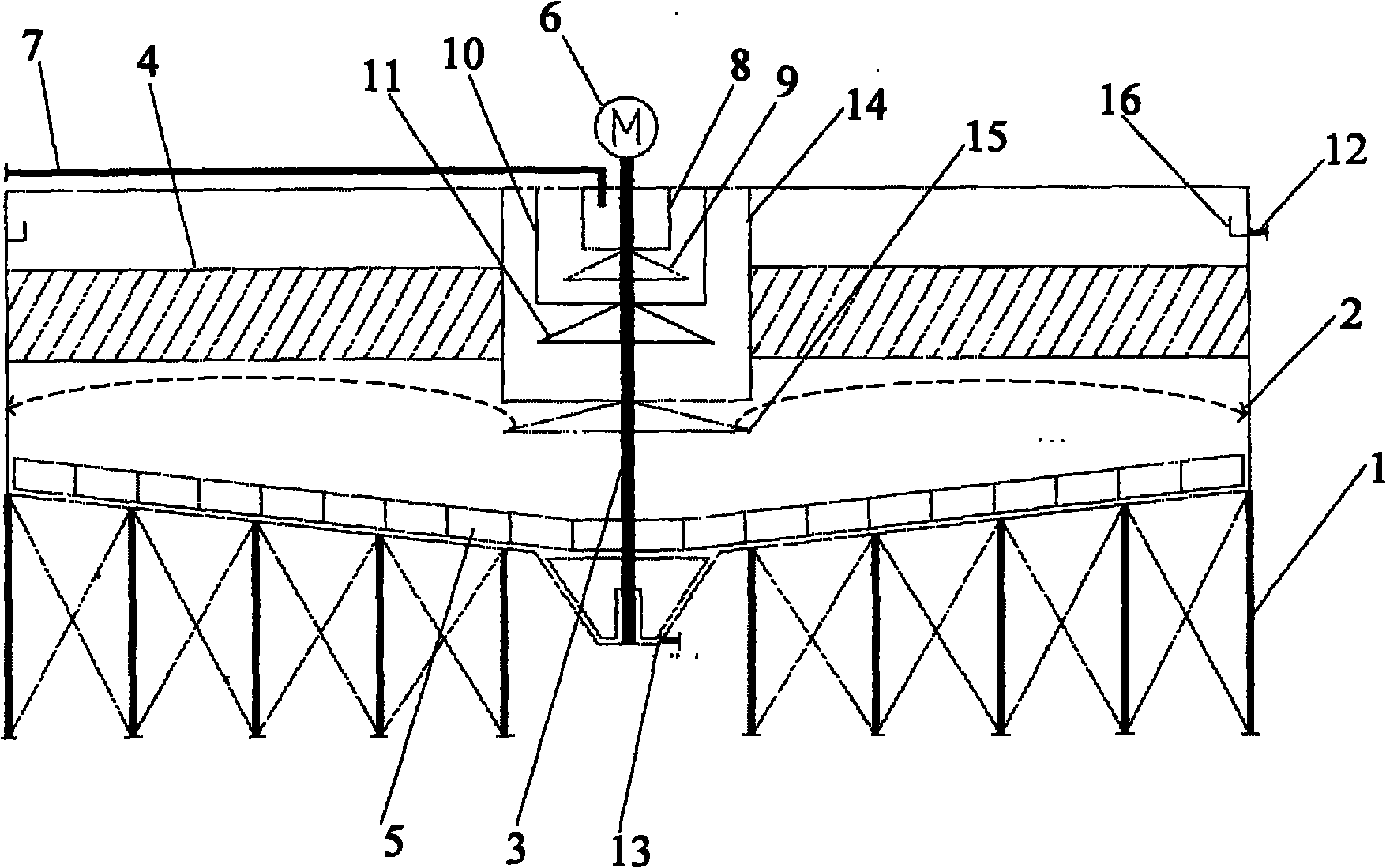

[0024] The difference between this embodiment and Embodiment 1 is that the guide device is three-stage, the three-stage guide tube 14 is set on the outside of the second-stage guide tube 10 and the second-stage reflector 11, and the third-stage reflector 15 is placed on the third Below the first-stage guide tube 14 , the swash plate 4 is placed between the outside of the third-stage guide tube 14 and the side wall of the cylinder body 2 .

[0025] When this embodiment is used, the gray water enters the first-stage diversion tube 8 from the gray water inlet, reflects the water distribution through the first-stage reflector 9 into the second-stage guide tube 10, and then reflects the water distribution through the second-stage reflector 11 to the third stage. In the first-stage guide tube 14, the water is distributed into the cylinder through the reflection of the third-stage reflector 15, and the gray water flow rate of the gray water inlet 7 is just so that the gray water passi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com