Method and device for determining direction of carbon block in carbon block cleaning machine set

A carbon block and unit technology, which is applied in the field of carbon block cleaning units, can solve problems such as damage to workers' health, wrong direction judgment by the control system, and harsh working environment, and achieve the effects of improving product qualification rate, reducing labor costs, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

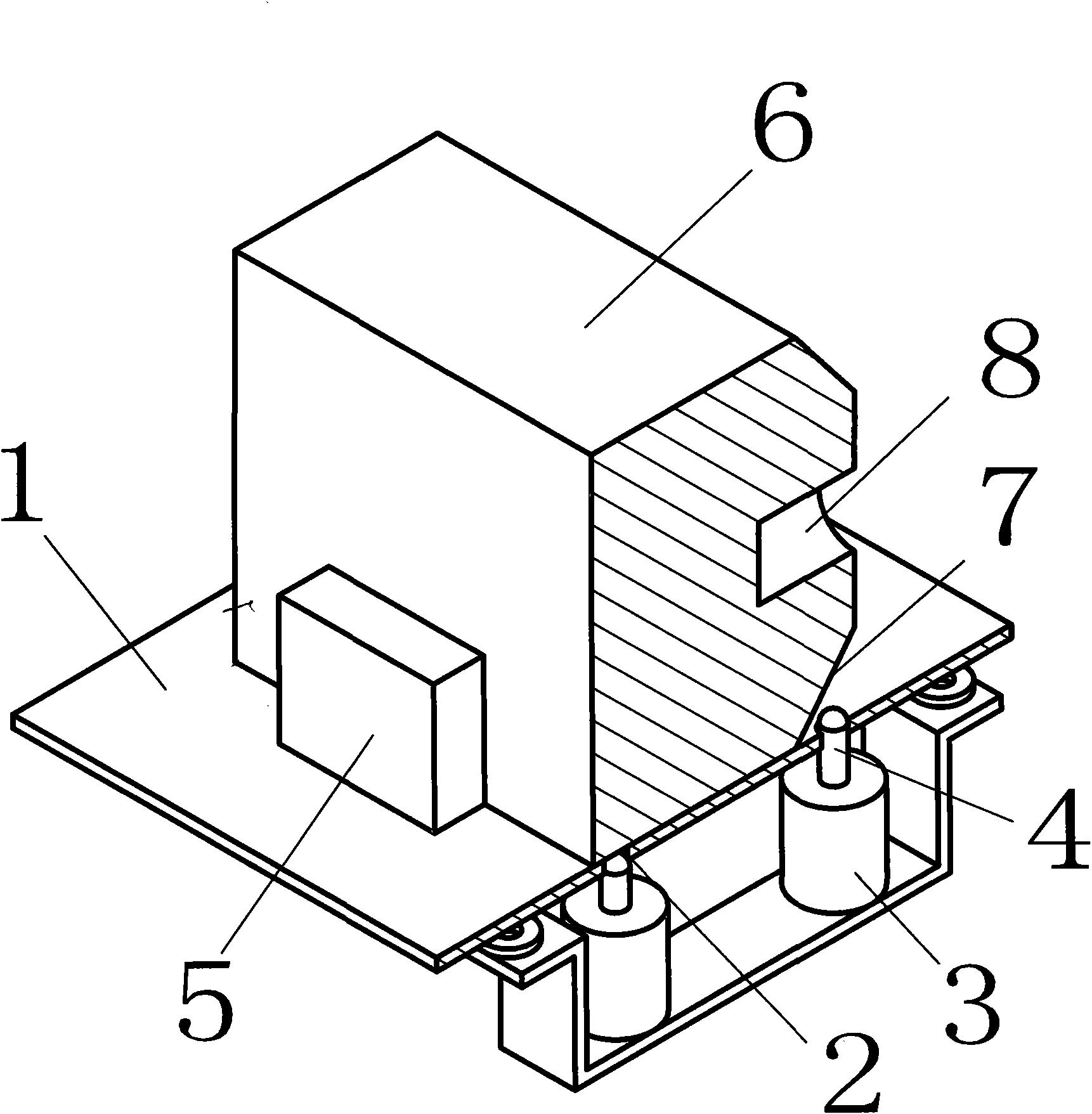

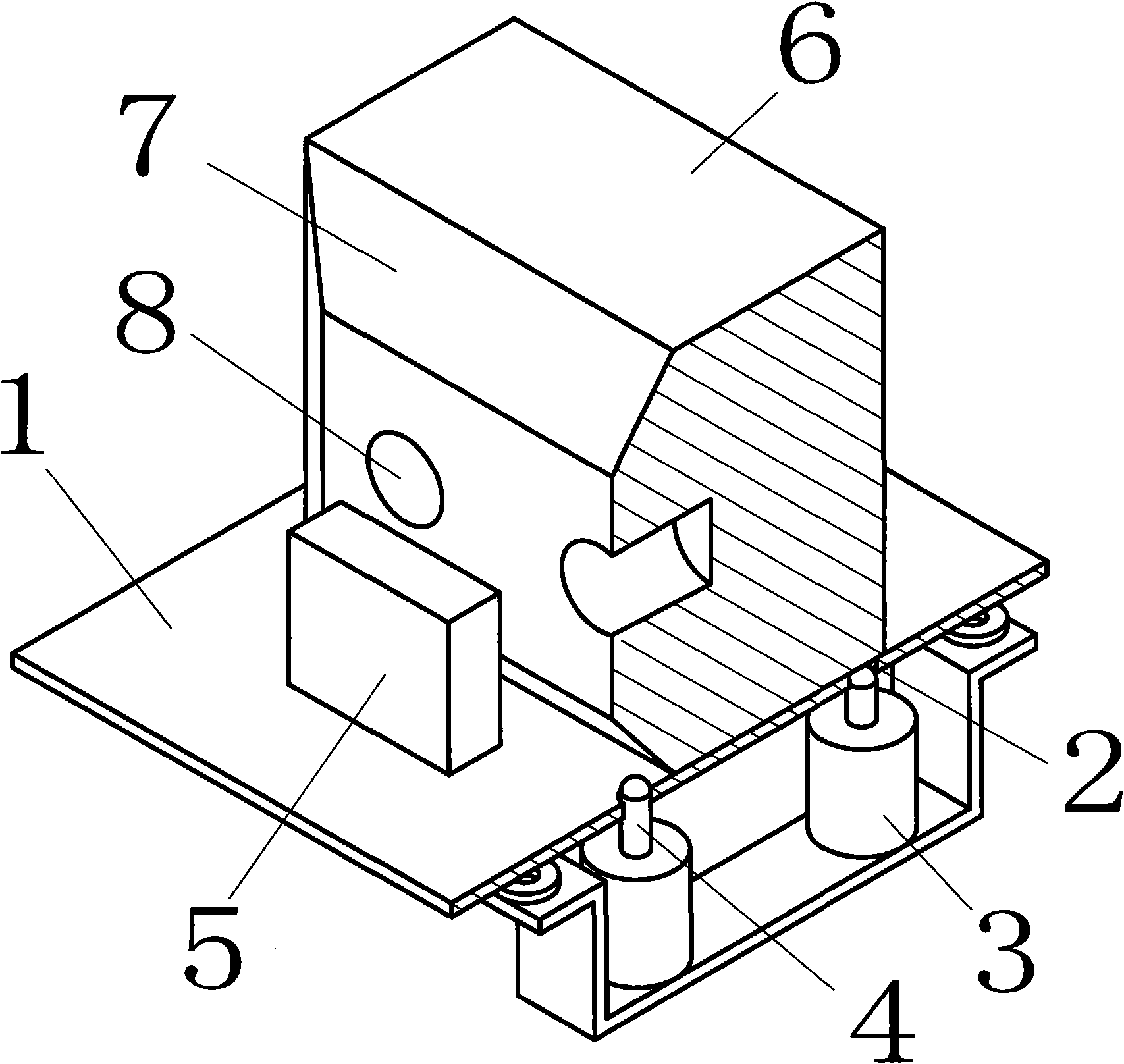

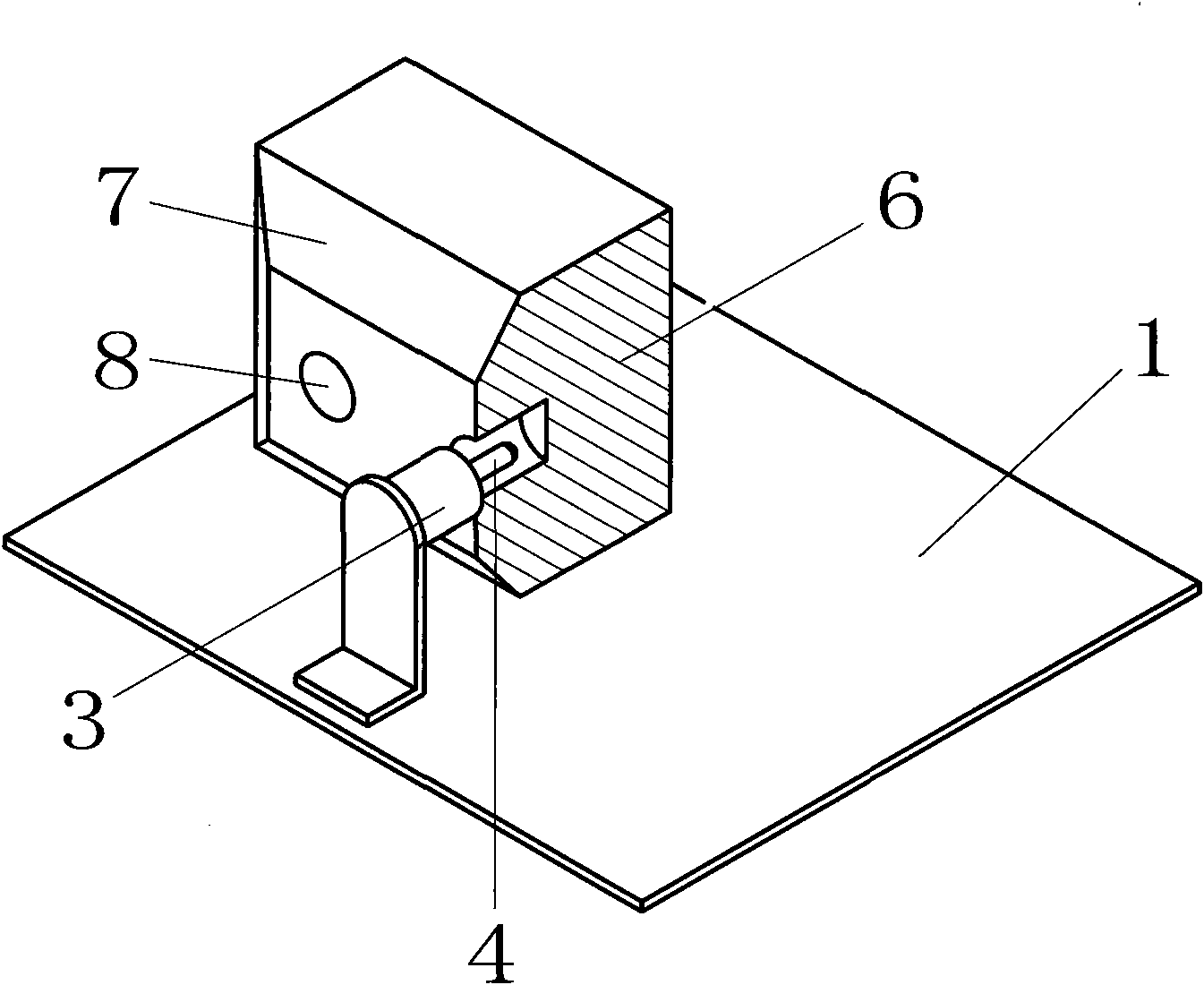

[0021] Example. Carbon blocks that need to determine the direction such as Figure 5 As shown, the shape of the carbon block 6 is a rectangular cube, the bottom surface is a plane, the top surface is provided with a bowl hole, the edge of the top surface is chamfered, the height is H, the length is L, and the width is W. When charcoal block 6 is in the calciner, its arrangement is as follows: Figure 6 As shown, one piece is arranged with the top facing up and the other piece is arranged with the bottom facing up, and the arrangement is also the same when it comes out of the oven. Therefore, when the carbon block is laid down sideways, some of the top surfaces are facing to the left and some are to the right. Therefore, before the carbon block enters the cleaning station, it is necessary to accurately judge the orientation of the top and bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com