Oil shielding device for evaporation

An oil shielding and oil-gas technology, which is applied in vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the problems of uncontrolled oil flow, high use cost, and rapid oil aging, and achieve cost reduction, Aging time becomes longer and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

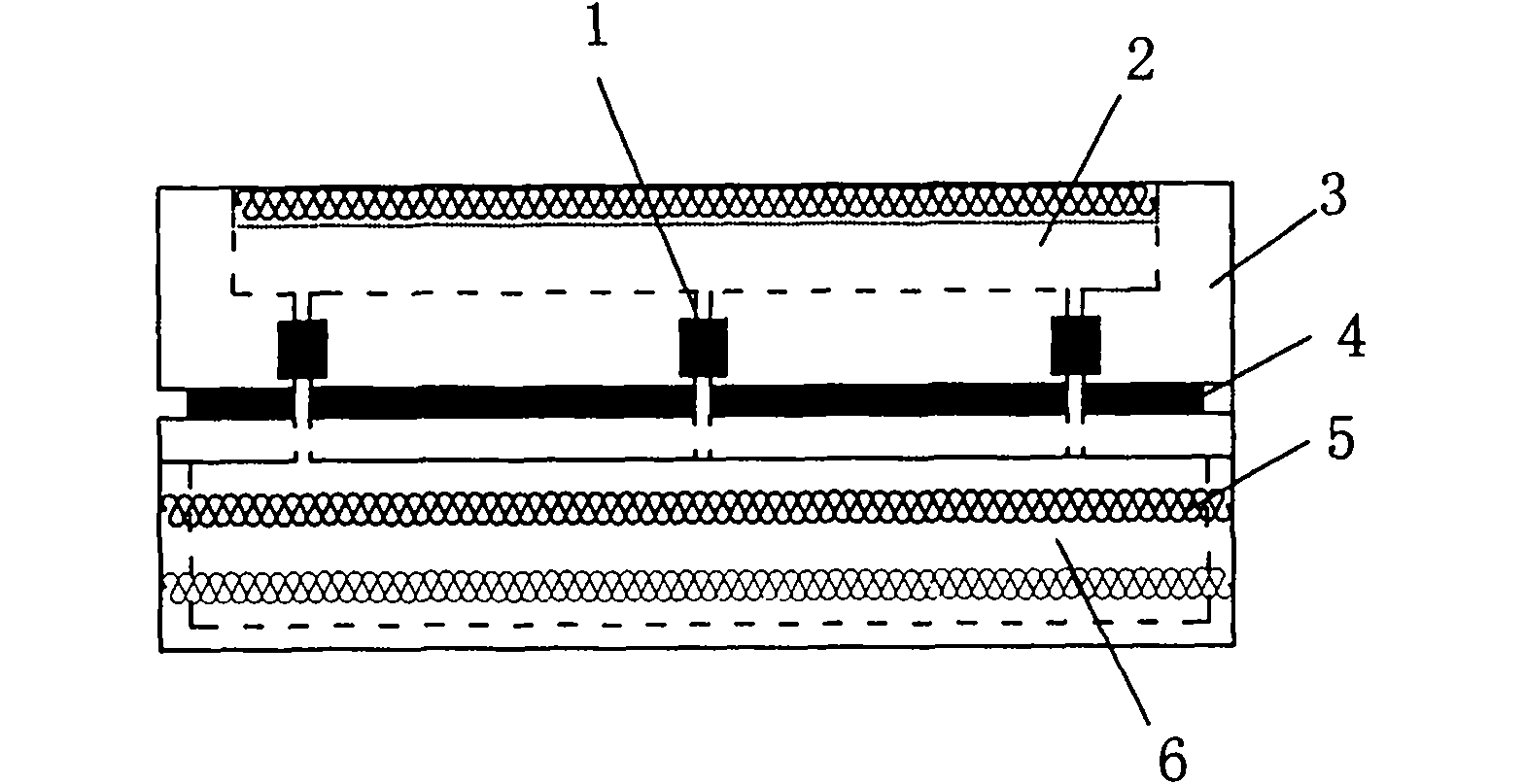

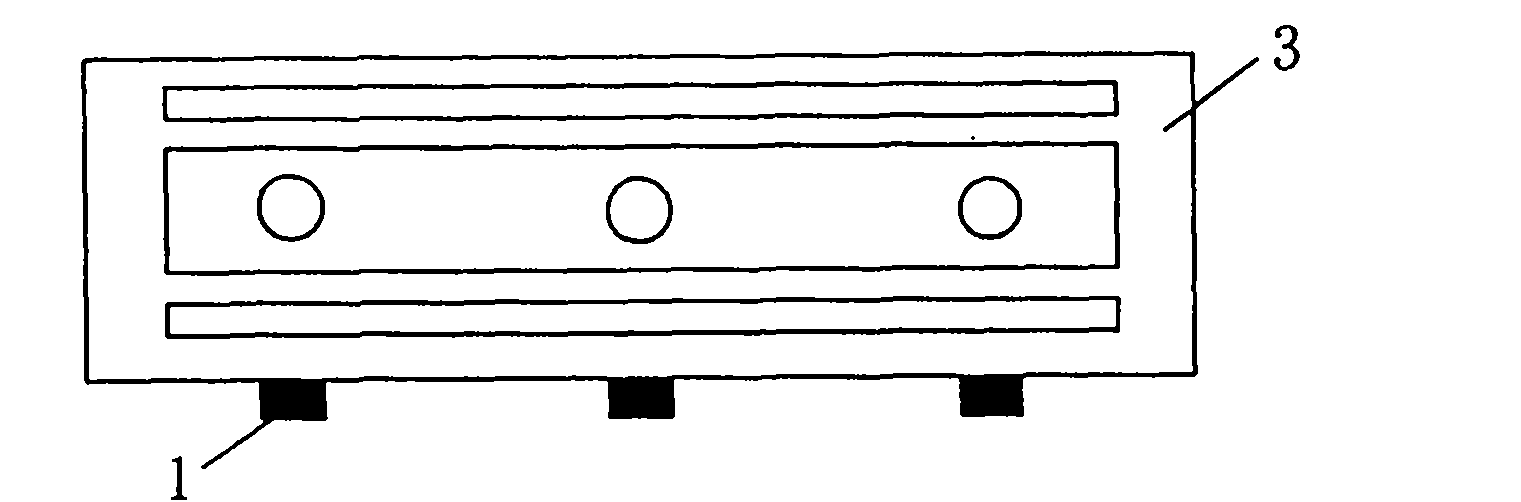

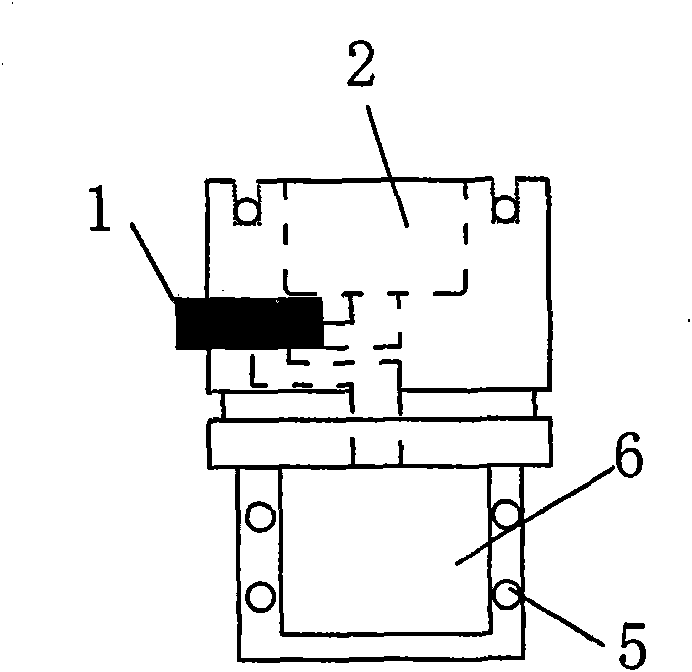

[0012] An oil shielding device for vapor deposition of the present invention, such as figure 1 , figure 2 , image 3 As shown, it includes an oil-gas tank 3 divided into an upper chamber 2 and a lower chamber 6, a solenoid valve 1 connecting the upper chamber 2 and the lower chamber 6, and a heat pipe 5 for heating the upper chamber 2 and the lower chamber 3 respectively, and the oil-gas tank 3 It is filled with oil, and a heat insulating board 4 is provided between the upper chamber 2 and the lower chamber 6 . The heating pipe 5 for heating the lower chamber 6 is located outside the lower chamber 6 and indirectly heats the oil in the lower chamber 6 . There are three solenoid valves 1, which are evenly distributed on the two ends and the center of the outer wall of the oil-gas tank 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com