Double-stage dynamic microelectrolyzing device

A technology of dynamic micro-electrolysis and micro-electrolysis cell, which is applied in water/sewage multi-stage treatment, water/sewage treatment, water/sludge/sewage treatment, etc. The problem of high power consumption of the electrolysis device achieves the effects of reduced power consumption and operating costs, less equipment investment, and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

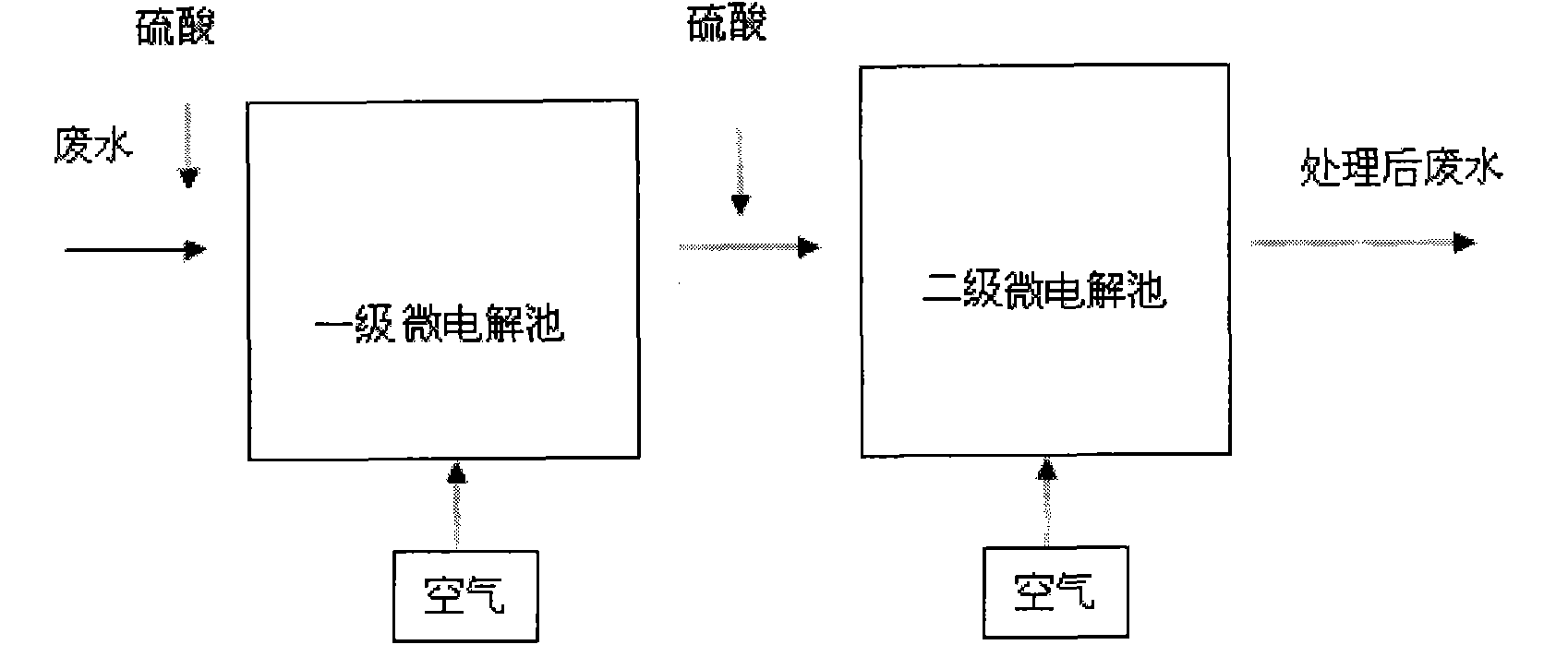

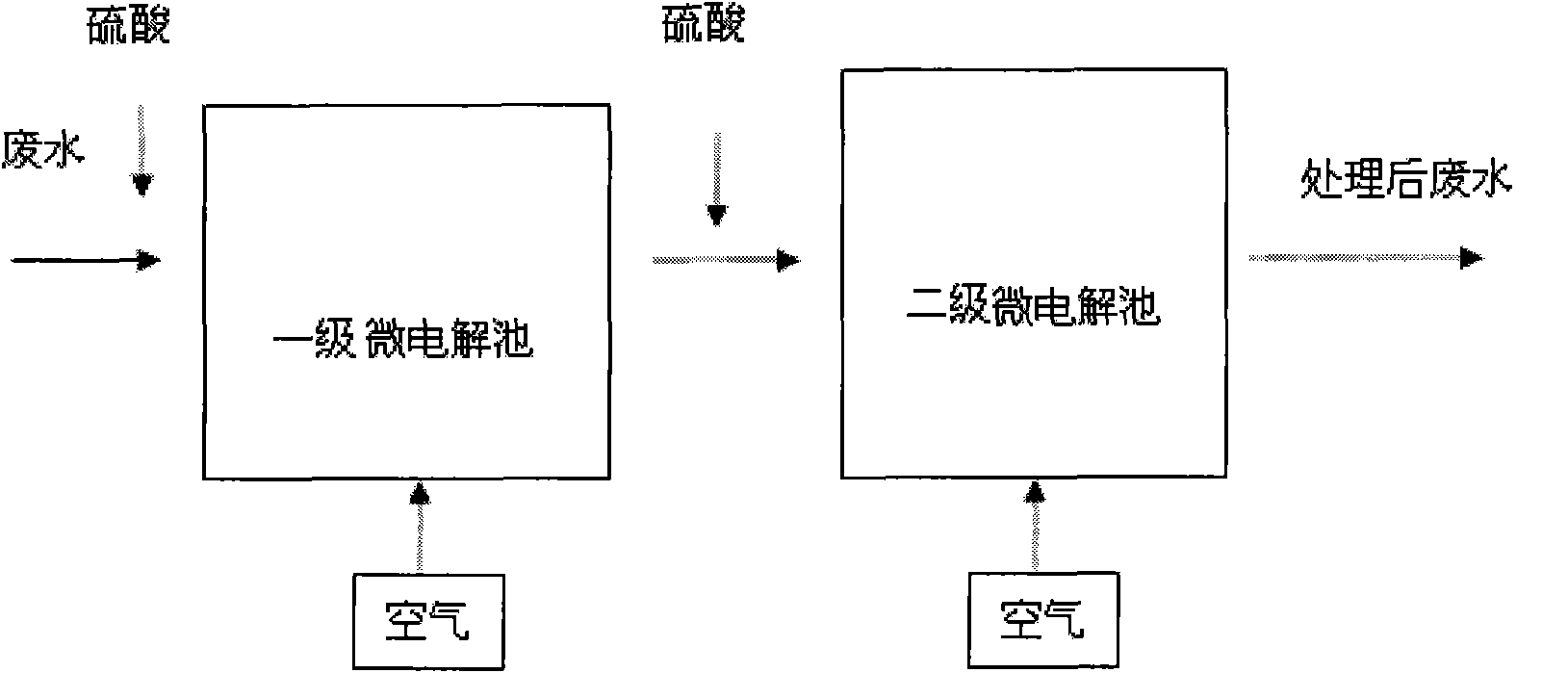

[0027] A two-stage dynamic micro-electrolysis device, comprising a primary micro-electrolysis cell and a secondary micro-electrolysis cell; the primary micro-electrolysis cell and the secondary micro-electrolysis cell are connected in series; between the primary micro-electrolysis cell and the secondary micro-electrolysis cell Acid is added to the series pipeline;

[0028] The above-mentioned first-level micro-electrolytic cell is fed into air during work, and the filler in the first-level micro-electrolytic cell is a mixture of steel chips and activated carbon, and the mass ratio of steel chips and activated carbon is 9: 1;

[0029] The above-mentioned secondary micro-electrolytic cell is fed into air during work, and the filler in the secondary micro-electrolytic cell is a mixture of steel chips and activated carbon, and the mass ratio of steel chips and activated carbon is 9: 1;

[0030] The above-mentioned acid is 10% dilute sulfuric acid.

[0031] work process:

[0032]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com