Alternating-current asynchronous motor frequency converter without speed sensor

A technology of AC asynchronous motor and frequency converter, which is applied in the direction of AC motor control, generator control, motor generator control, etc., which can solve the problems of inconvenient debugging and monitoring of frequency converters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

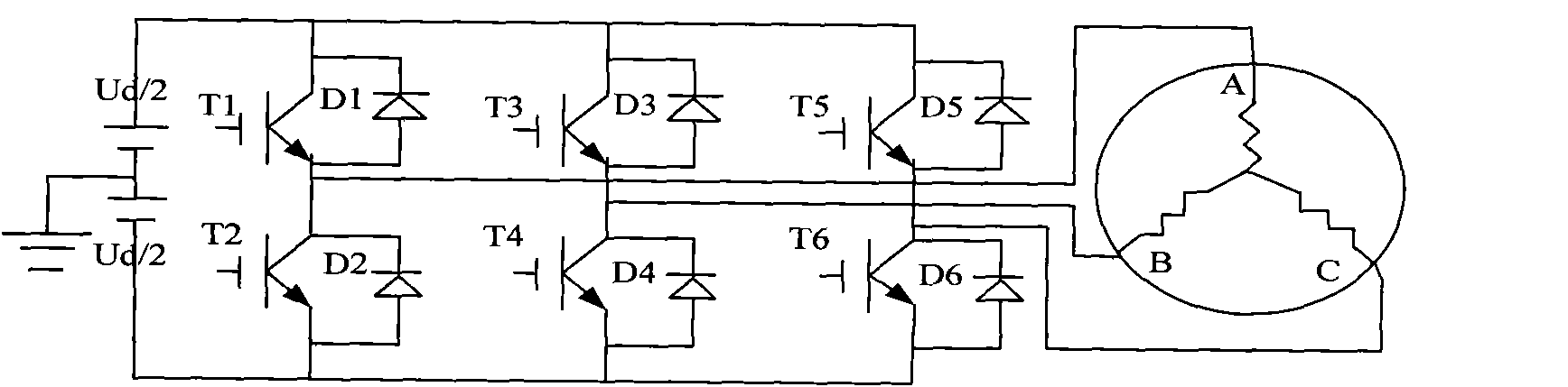

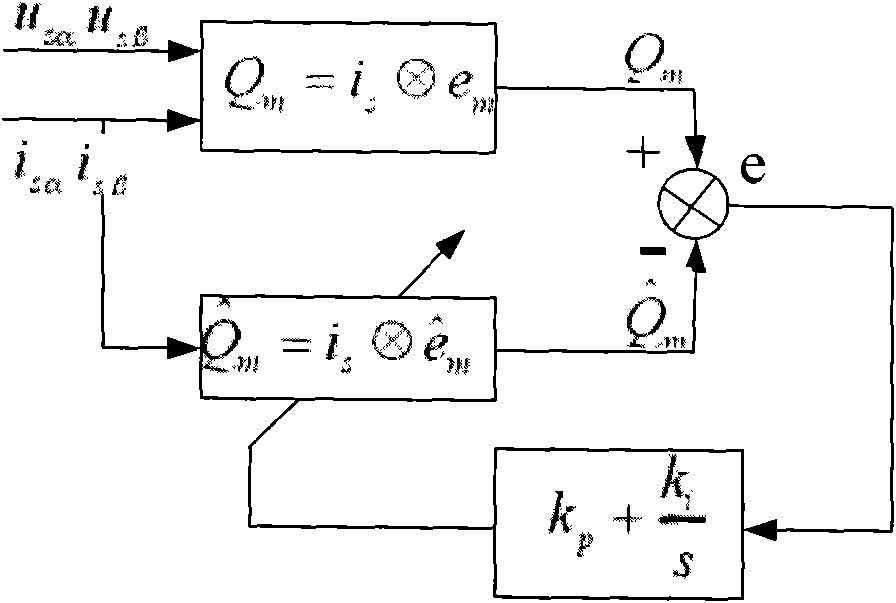

[0027] Such as figure 1 As shown, it is a main loop of closed-loop vector control of an AC asynchronous motor without a speed sensor. The main contents of the offline identification of the motor parameters and the online identification of the speed include:

[0028] 1. Off-line identification of stator resistance

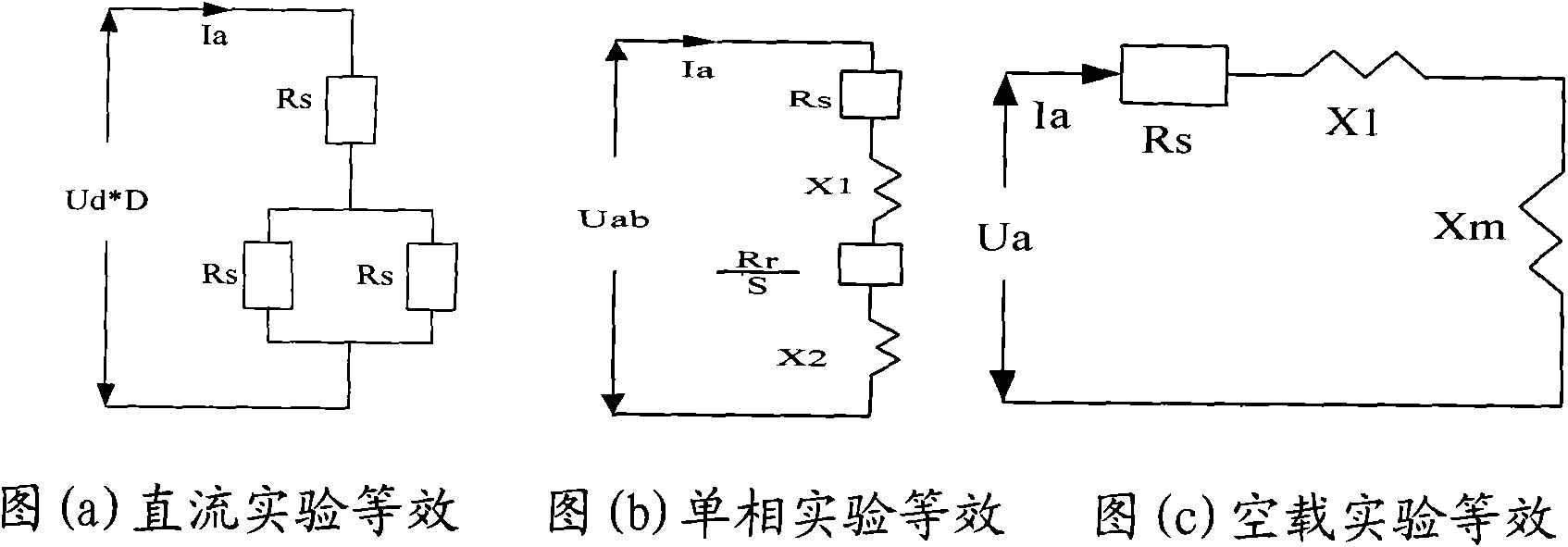

[0029] Such as figure 1 As shown, keep T3 and T5 off, keep T2, T4 and T6 on, apply a high-frequency pulse to T1, first set a small duty cycle D, and then gradually increase the duty cycle until the output current reaches Rated value, at this time, detect the output current value of the motor and the duty cycle D, and then calculate the stator resistance value. Equivalent circuit such as figure 2 (a) shown.

[0030] exist figure 2 In the circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com