Accelerator control system of mini-tiller

A technology of throttle control and micro-tiller, which is applied in the field of micro-tiller, can solve the problems that the adjustment handle is not well positioned, the limit is not obtained, and the controllability of the micro-tiller is poor, so as to achieve simple connection and Reliable, low manufacturing cost, simple and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

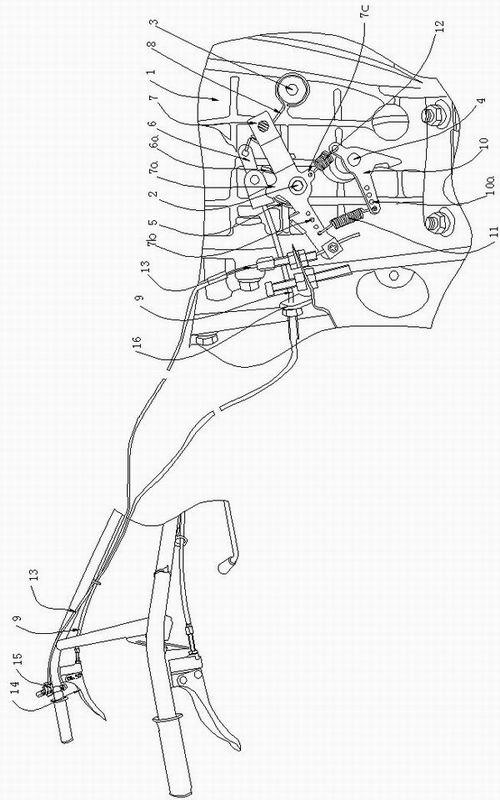

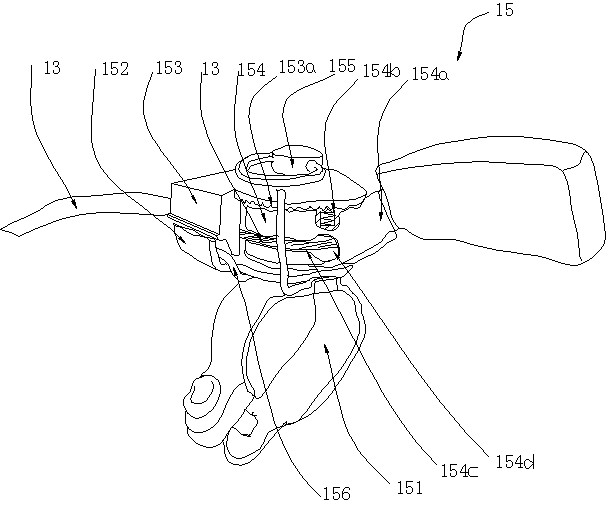

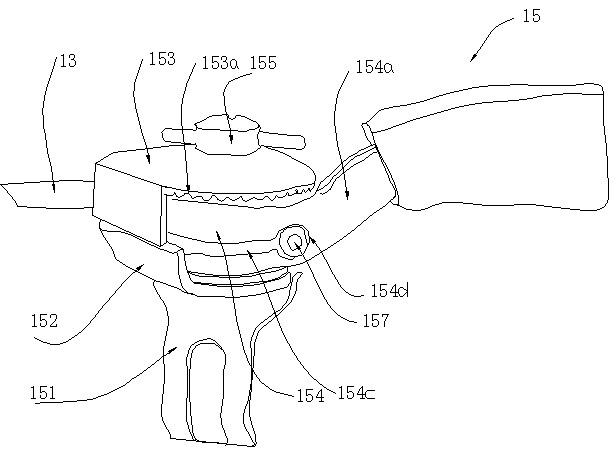

[0021] Such as Figure 1 ~ Figure 4The throttle control system of a tiller shown is provided with a control arm mounting column 2 and a spring mounting column 3 on the crankcase body 1, and the spring mounting column 3 is located on the right side of the control arm mounting column 2, and the Both the control arm mounting column 2 and the spring mounting column 3 are located above the throttle 4, and the throttle arm 10 is installed on the throttle 4, and the throttle return knob is sequentially set on the control arm mounting column 2 from the inside to the outside. Spring 5, reset support 6 and throttle control arm 7, wherein the inner end of the throttle return torsion spring 5 is fixed on the control arm mounting column 2, and the outer end is hooked on the left part of the throttle control arm 7; The lower end of the support 6 is installed on the mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com