Method for moulding high-strength steel semichord pipe

A technology of high-strength steel and forming method, applied in the direction of slender components, building components, etc., can solve the problems of uneven performance of hot-pressed half-chord tubes, unreleasable stress, easy cracks, etc., so as to reduce the repair time. And cost, performance uniform and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

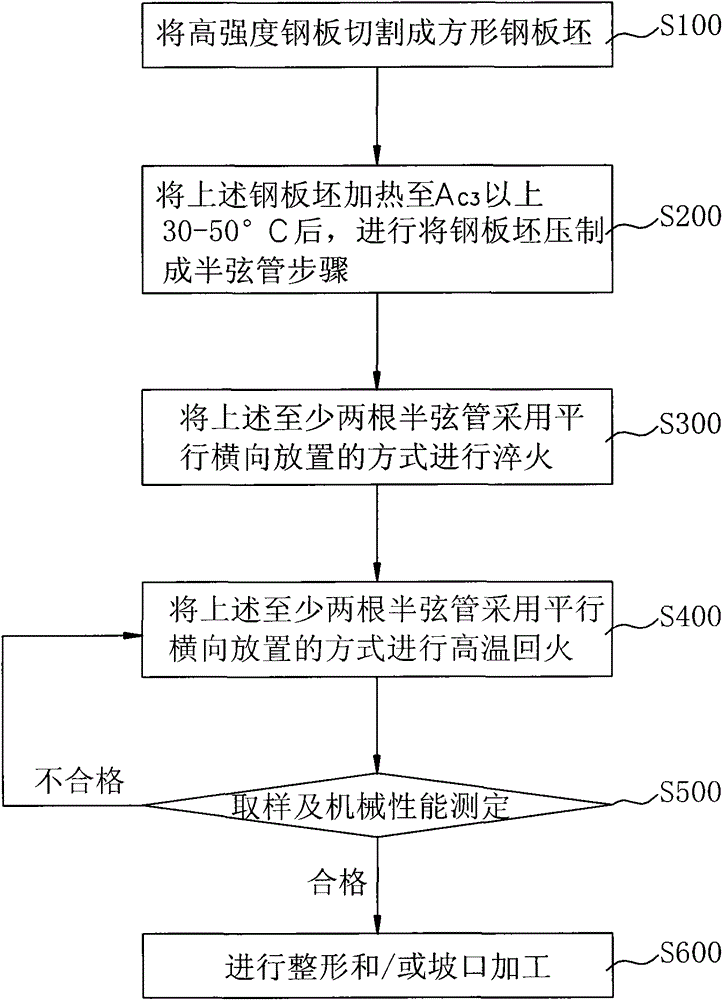

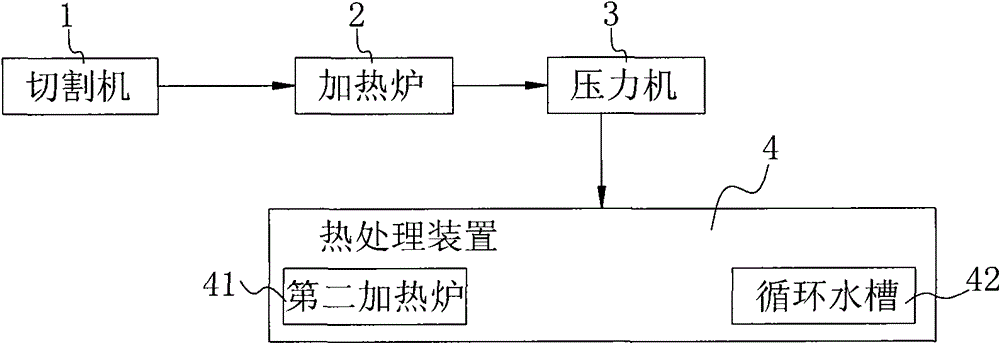

[0043] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

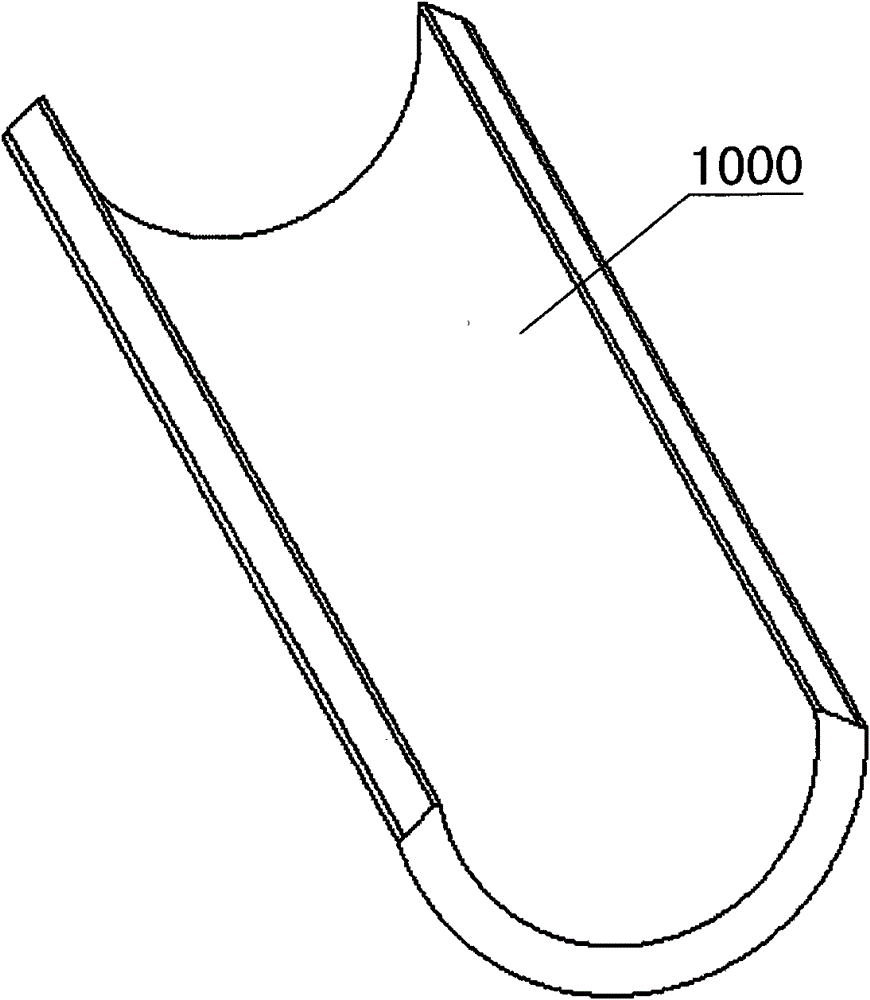

[0044] Such as figure 1 As shown, the half-chord 1000 involved in the present invention is a high-strength steel half-chord, which is mainly used in the construction of pile legs of jack-up drilling platforms in marine engineering. It should be noted that the high-strength steel mentioned in the present invention refers to the yield Quenched and tempered alloy steel with a strength above 690Mpa. However, for quenched and tempered alloy steels with a yield strength lower than 690Mpa, if the method of the present invention is used to process half-chord pipes, if only the heating temperature, heat preservation, and pressure holding time a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com