Optical fiber ring winding method

A manufacturing method and optical fiber technology, which are applied in the field of point-symmetrical winding of optical fiber rings, can solve the problems such as the inability to strictly guarantee the position of the center point of the optical fiber, and achieve the effects of easy installation and operation, lowering the full temperature temperature coefficient, and good anti-vibration performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

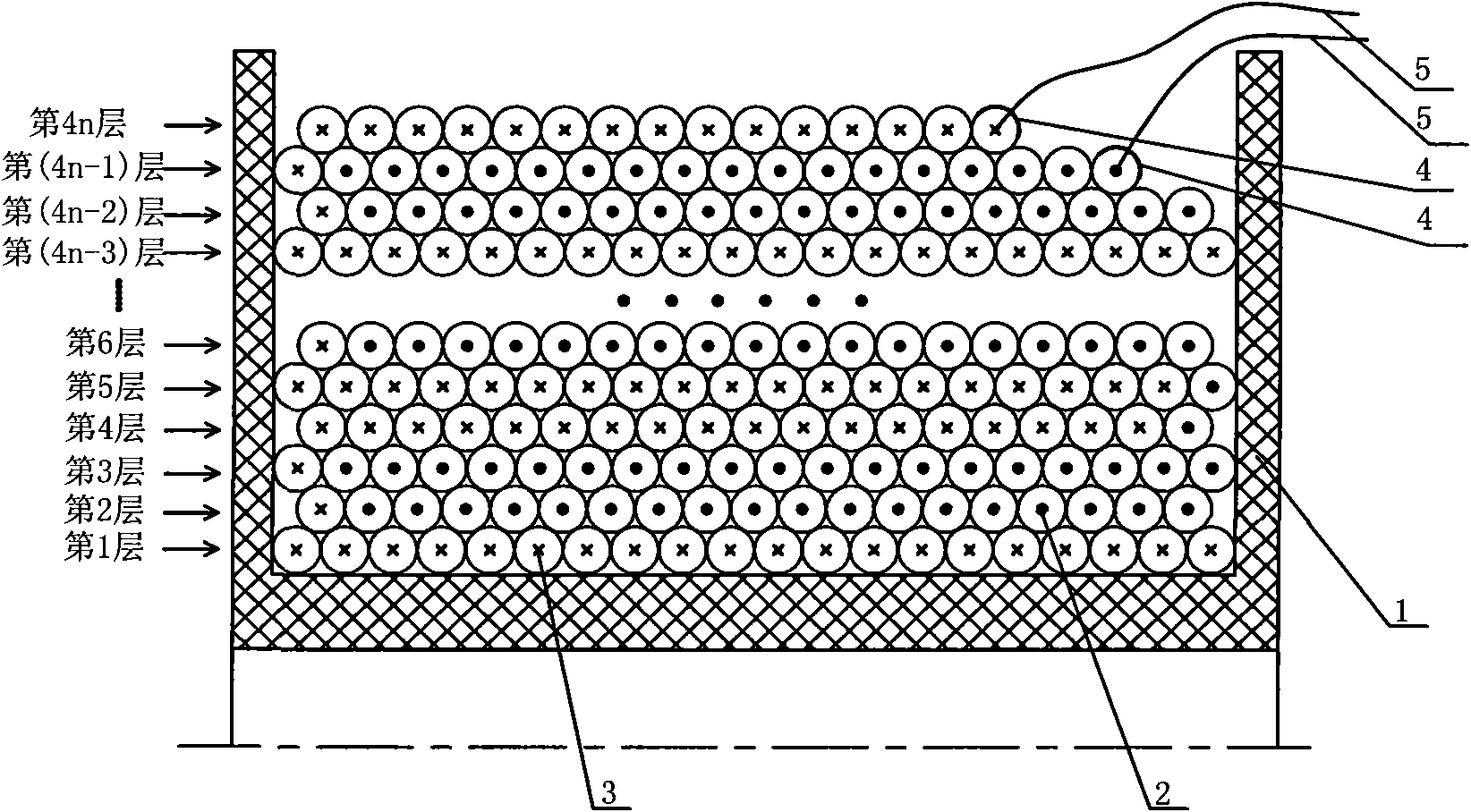

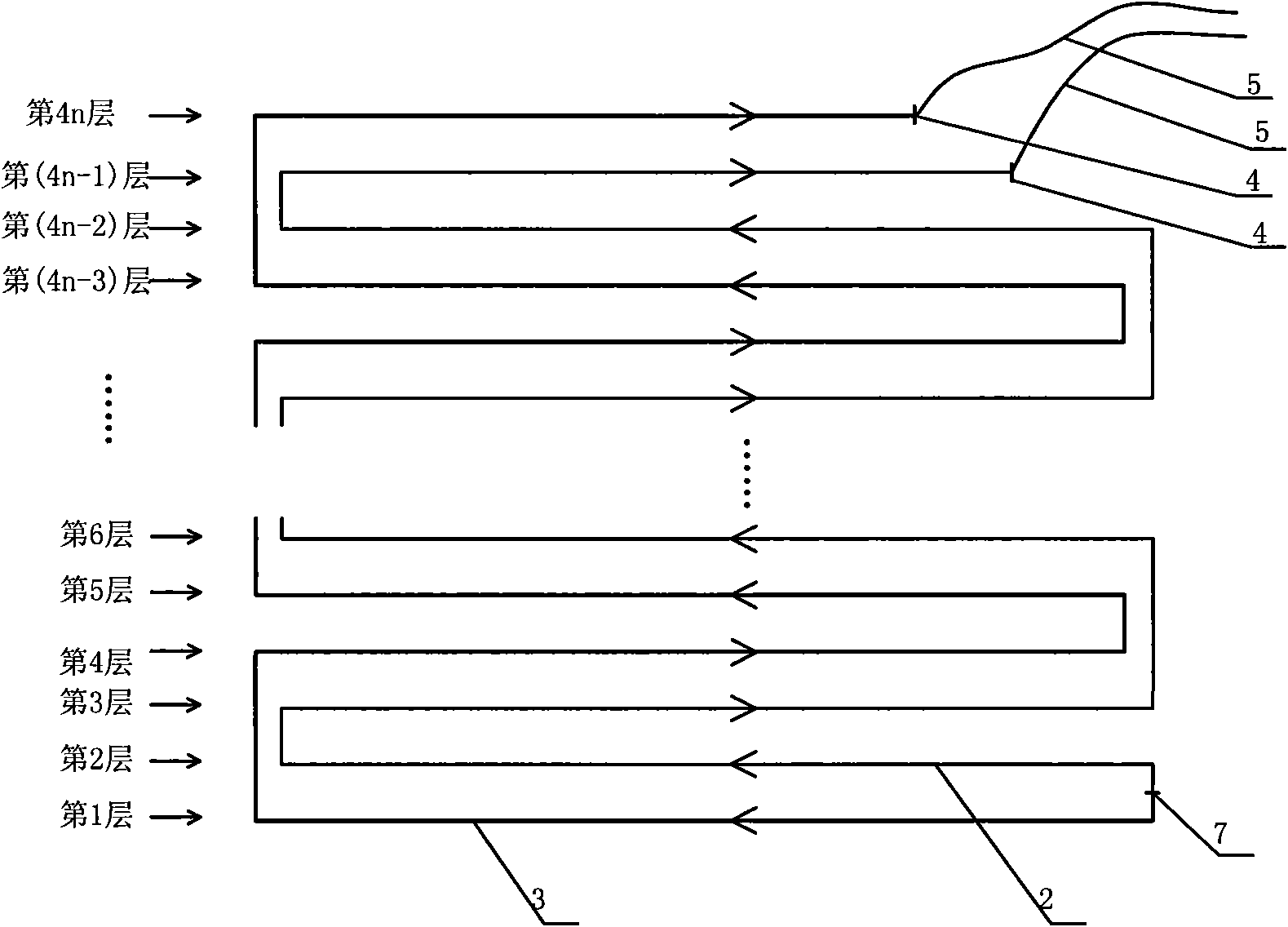

[0031] A method for wrapping an optical fiber, comprising the steps of:

[0032] 1] Calculate the required optical fiber length, measure the optical fiber of the calculated length, and leave enough optical fiber pigtails at both ends 5;

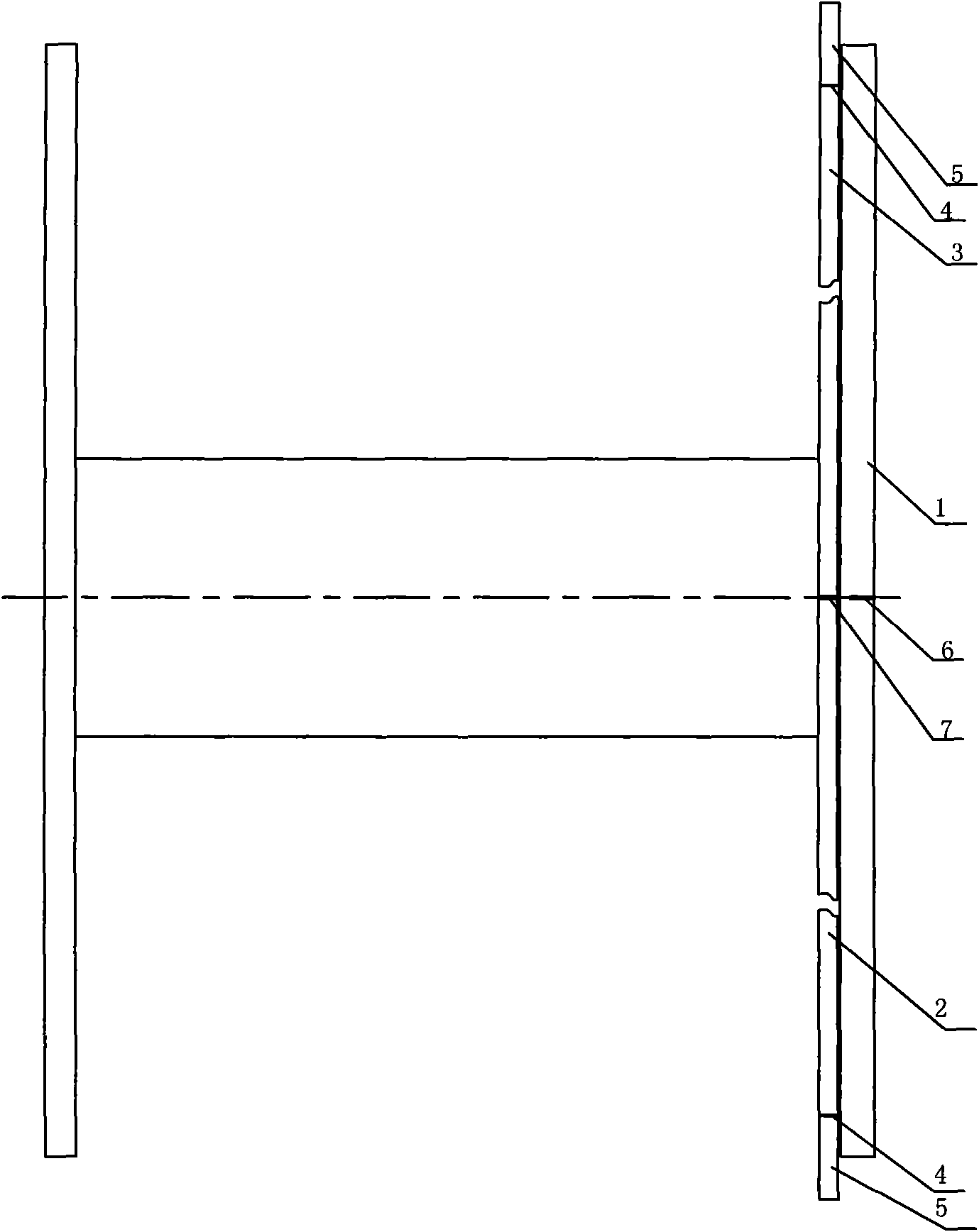

[0033] 2] Make an end point mark 4 at the two ends of the calculated length of the optical fiber, and make a midpoint mark 7 at the midpoint between the two end points of the optical fiber; make a straight line mark 6 on the outer circumference of the left wall of the skeleton 1 along the direction of the skeleton axis;

[0034] 3] Attach the optical fiber to the innermost part of the left wall of the fiber ring perpendicular to the axis of the frame 1, and align the fiber midpoint mark 7 with the straight line mark 6 of the frame;

[0035] 4] Wind the optical fiber according to the bipolar symmetrical winding method, quadrupole symmetrical winding method or octapole symmetrical winding method until the first half of the optical fiber 2 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com