Single iron core flux gate

A technology of fluxgate and single iron core, which is applied in the field of fluxgate, can solve the problems such as the difficulty of iron core processing, achieve the effect of convenient processing and winding, and ensure consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

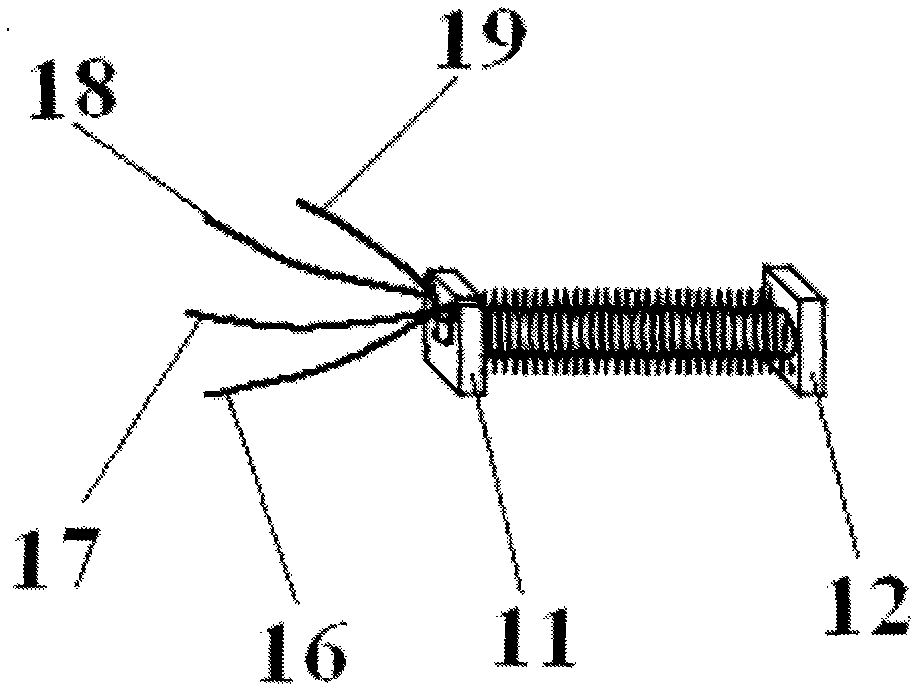

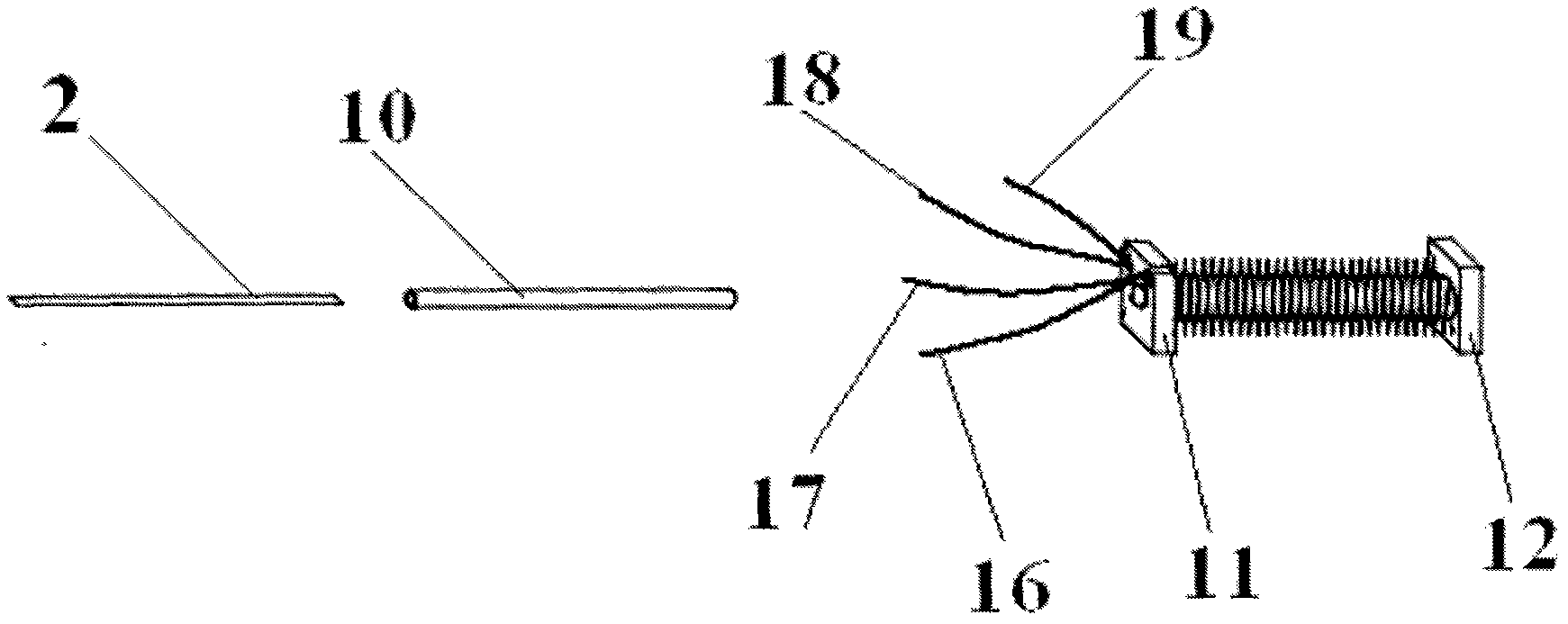

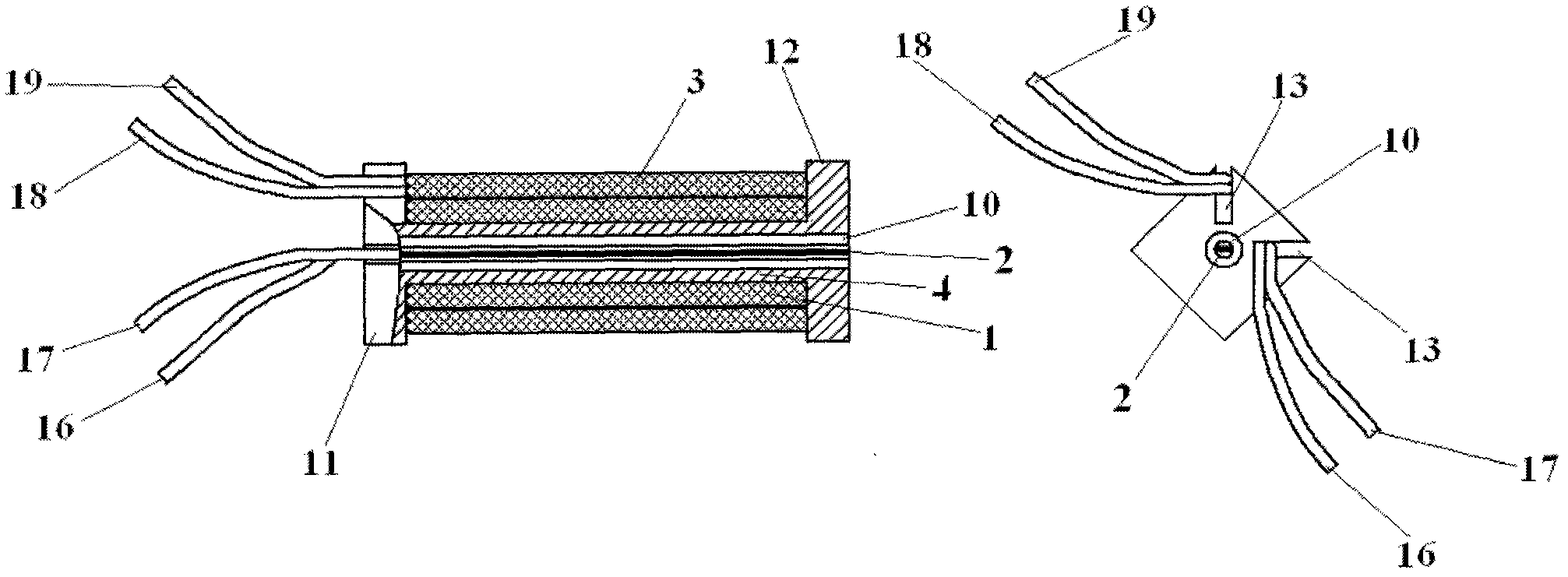

[0016] The following examples refer to Figure 1~3 .

[0017] The single-core fluxgate includes an exciting coil 1, an iron core 2, a measuring coil 3 and a skeleton 4, and also includes a flexible sleeve 10. The iron core 2 is in the shape of a strip, and the iron core 2 is made of permalloy or amorphous soft The magnetic material has a thickness between 0.02mm and 0.1mm, a width of 1mm, and the same length as the skeleton 4 with the round hole. The excitation coil 1 is wound on the inner layer of the skeleton 4 ; the measuring coil 3 is wound on the outer layer of the skeleton 4 . Both the front end 11 of the frame and the rear end 12 of the frame are square. Two lead wire grooves 13 are processed on the two corners of the front end 11 of the skeleton. The lead wire 16 at the input end of the excitation coil and the lead wire 17 at the output end of the excitation coil are drawn out from the lead wire groove 13 on the right side; the lead wire 18 at the input end of the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com