New wire separating and stranding machine

A branching machine, a new technology, applied in the direction of electrical components, inductors/transformers/magnets manufacturing, circuits, etc., can solve problems such as prone to defective products and fatigue, and achieve the effect of ensuring quality, reducing labor intensity, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

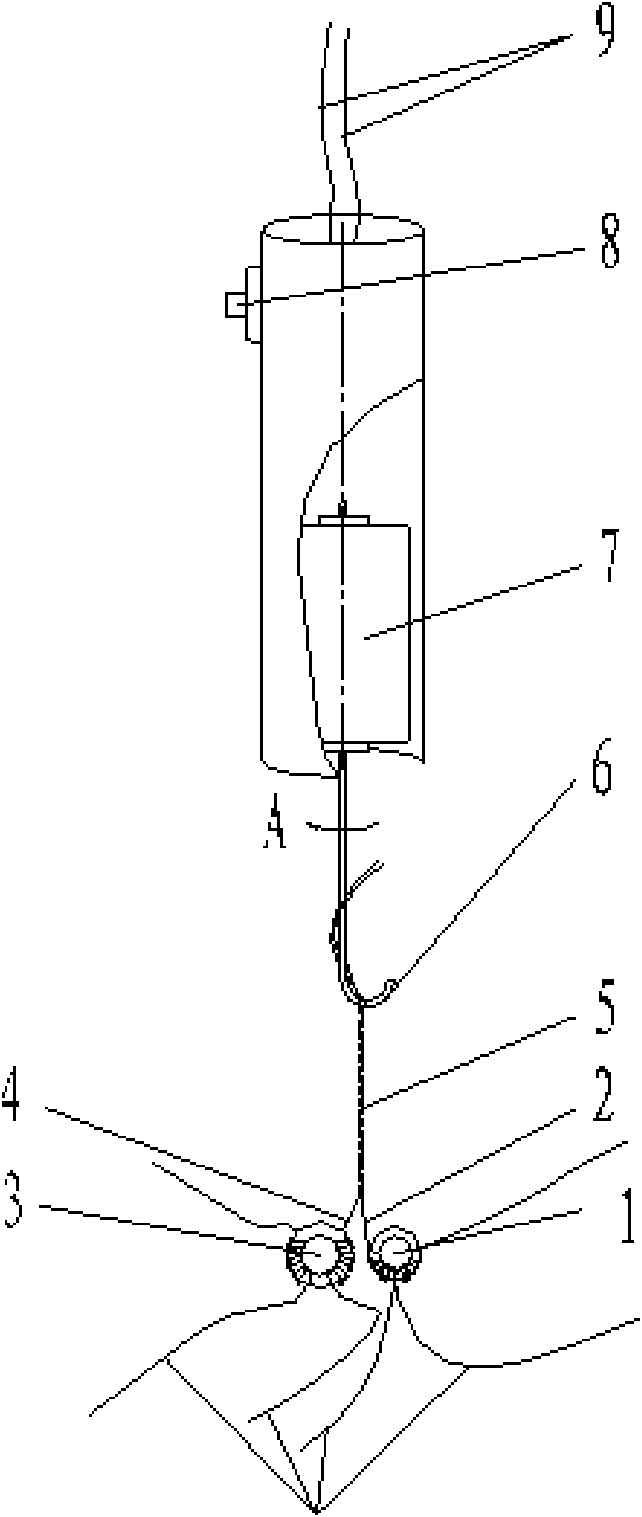

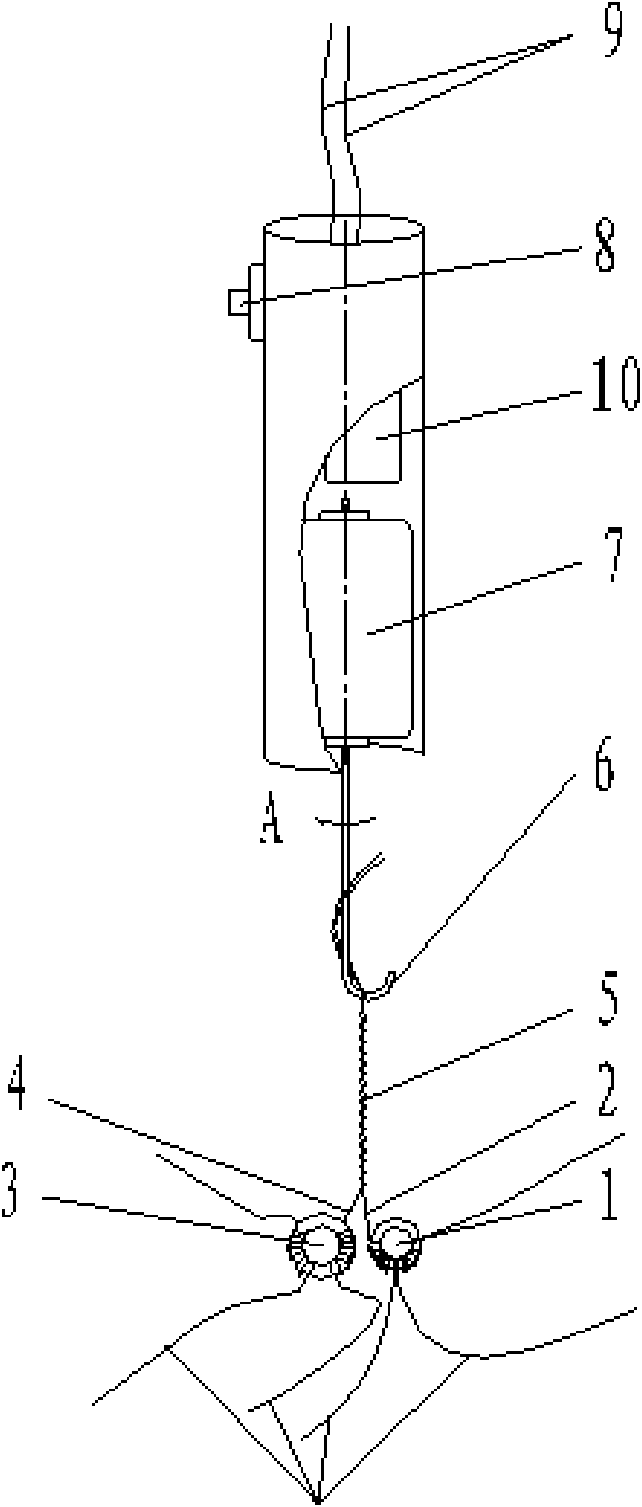

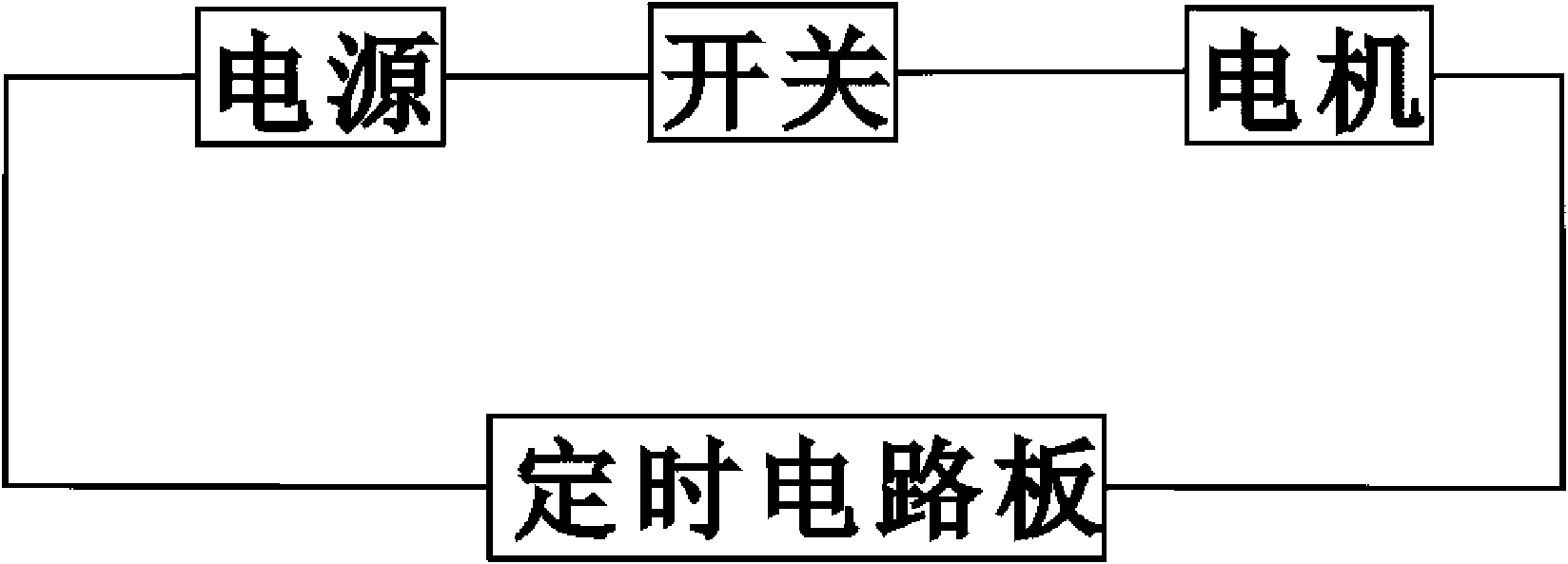

[0014] Embodiment 1: as figure 2 and 3 As shown, this new-style wire splitting machine comprises power supply 9, motor 7, winding hook 6 and switch 8, and motor 7 drives winding hook 6 to rotate, and timing circuit board 10 controls the rotation of motor, and this timing circuit board 10 and power supply 9, The motor 7 and the switch 8 form a closed loop.

[0015] When in use, separate an enameled wire h2 on the wire package TA1 and an enameled wire i4 on the wire package TB3 and then connect the twisted wire hook 6 at the lower end of the wire splitter. After the switch 8 is triggered, the timing circuit board 10 starts timing, and the motor 7 drives the twisted wire hook 6 to rotate along the direction A, and twists the enameled wire i4 and the enameled wire h2 into a twisted wire 5 . After the preset time, the motor 7 is automatically turned off, so that the running time of the motor 7 is precisely controlled, and there is no need to manually turn off the motor 7, ensuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com