Forklift hydraulic system matched with multi-functional wet brakes

A wet brake and hydraulic system technology, applied in the direction of brakes, brake transmissions, hydraulic brake transmissions, etc., can solve the problem that small tonnage forklifts cannot meet the oil source requirements of multi-functional wet brakes, and achieve rapid release and simplified management. Road system, accurate manipulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

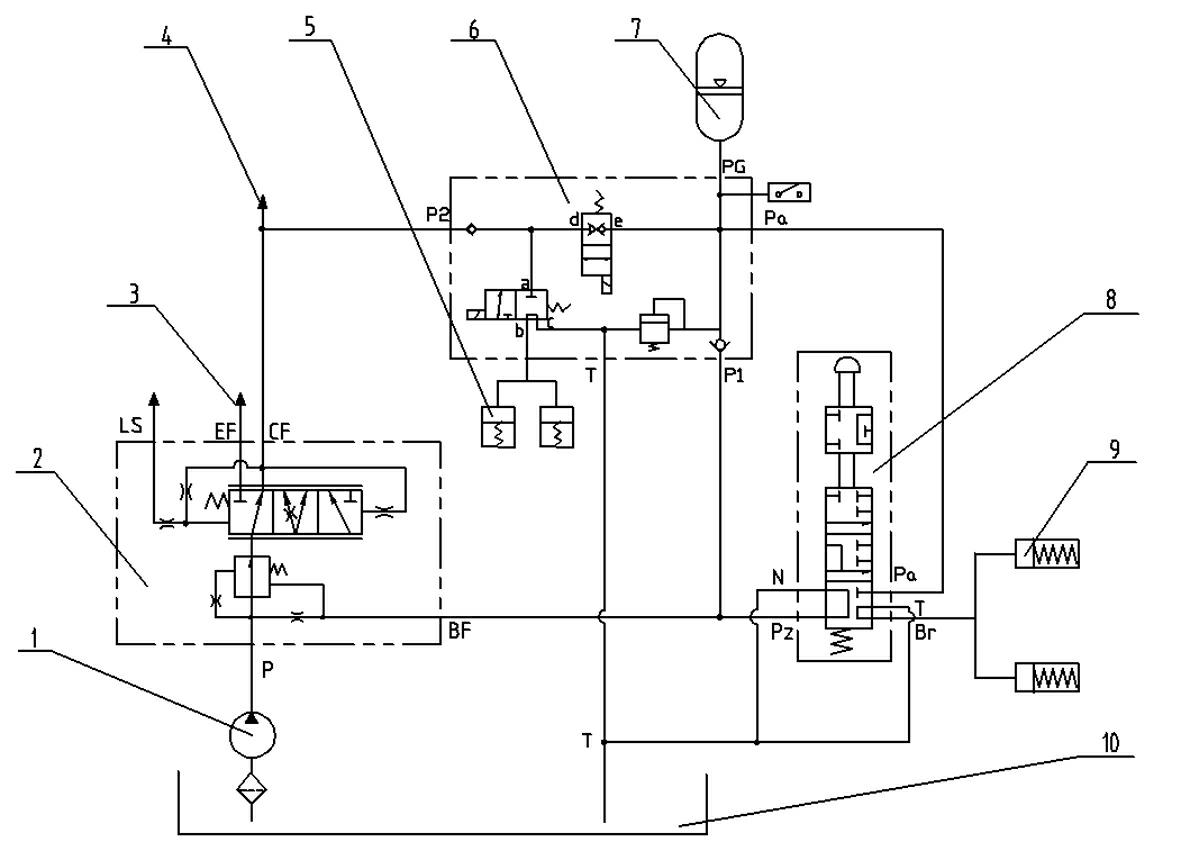

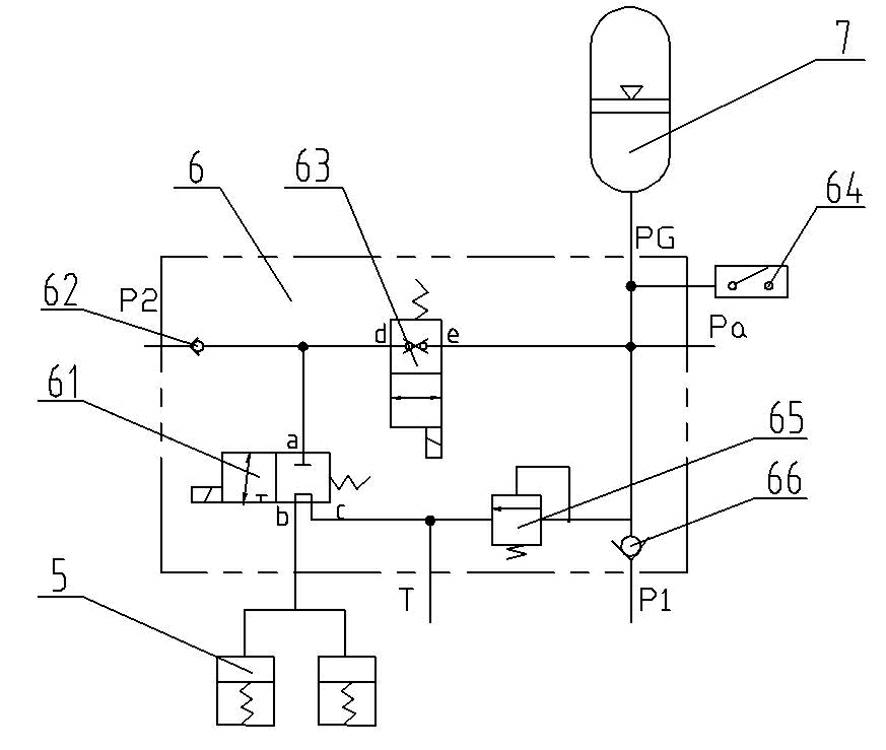

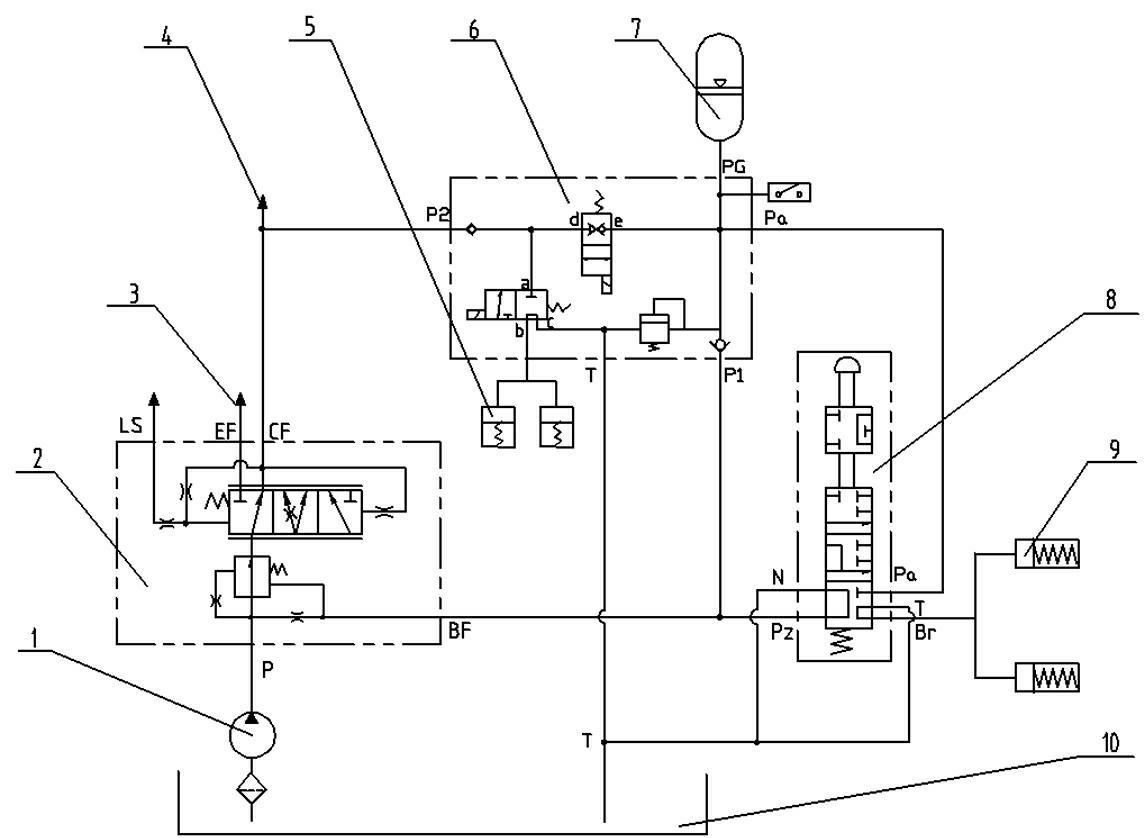

[0020] see figure 1 The forklift hydraulic system matching the multifunctional wet brake includes an oil pump 1, a priority diverter valve 2, an integrated valve block 6, an accumulator 7, a power brake valve 8, a parking brake 5, a service brake 9 and a fuel tank 10, each of which The parts are connected by oil pipes.

[0021] The oil outlet of the oil pump 1 communicates with the P port of the priority diverter valve 2. The priority diverter valve 2 has one inlet and three outlets, of which the first outlet is the BF port, which is divided into two routes through the BF port, and one route is connected to the integrated valve block 6. The P1 port is connected, and the other is connected with the Pz port of the dynamic brake valve 8; the second outlet is the EF port, and the EF port is connected with the forklift working device oil circuit 3; the third outlet is the CF port, and the CF port is also divided into two routes. One way communicates with the steering system 4 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com