Heavy-duty motorcycle frame

A motorcycle and heavy-duty technology, which is applied in the field of motorcycle frames, can solve the problems of short rear of the frame, easy breakage of the frame, insufficient strength of the beam tube and the beam plate, etc., and achieve the effect of strengthening the strength and strong load-carrying capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings of the description.

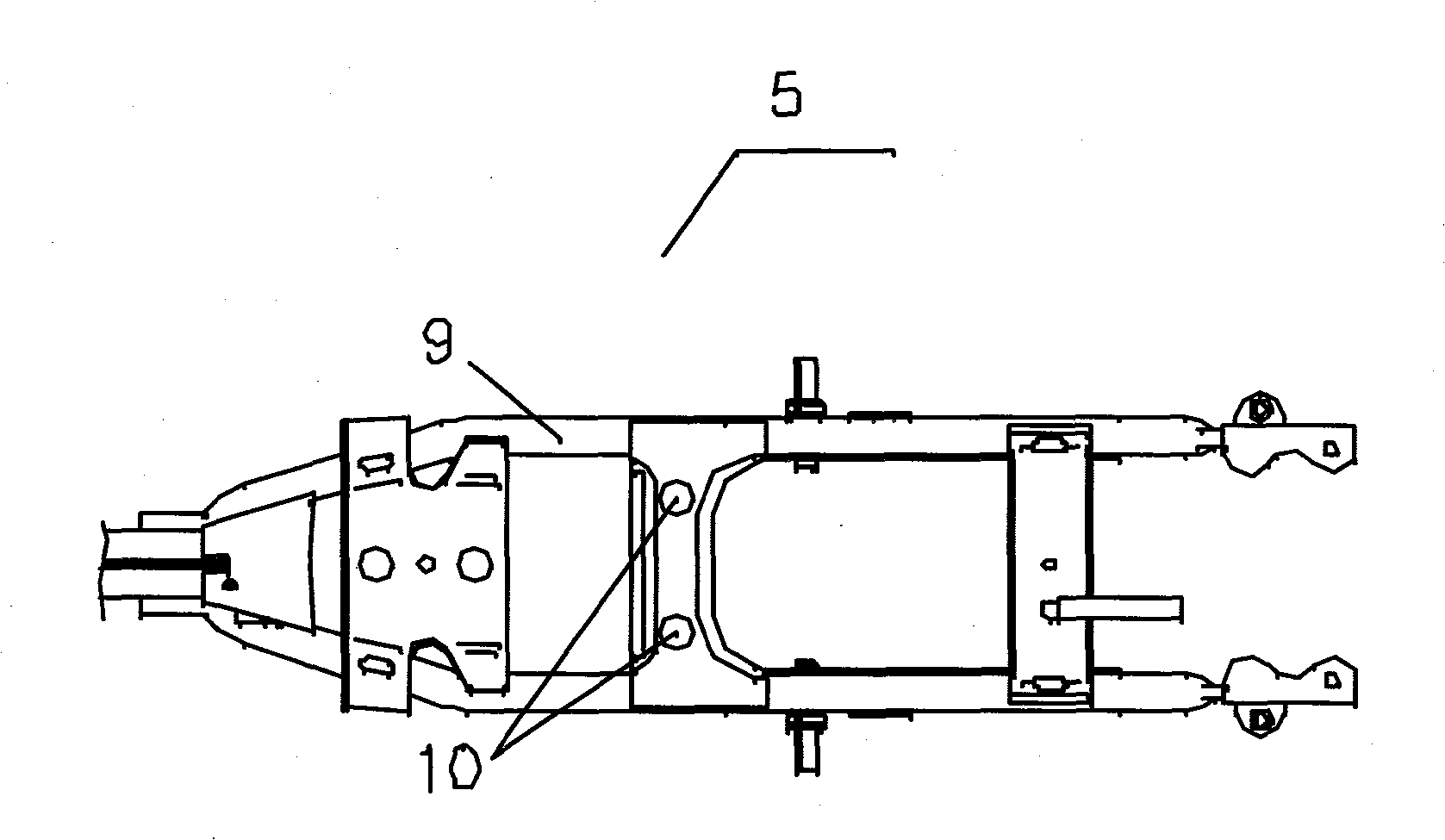

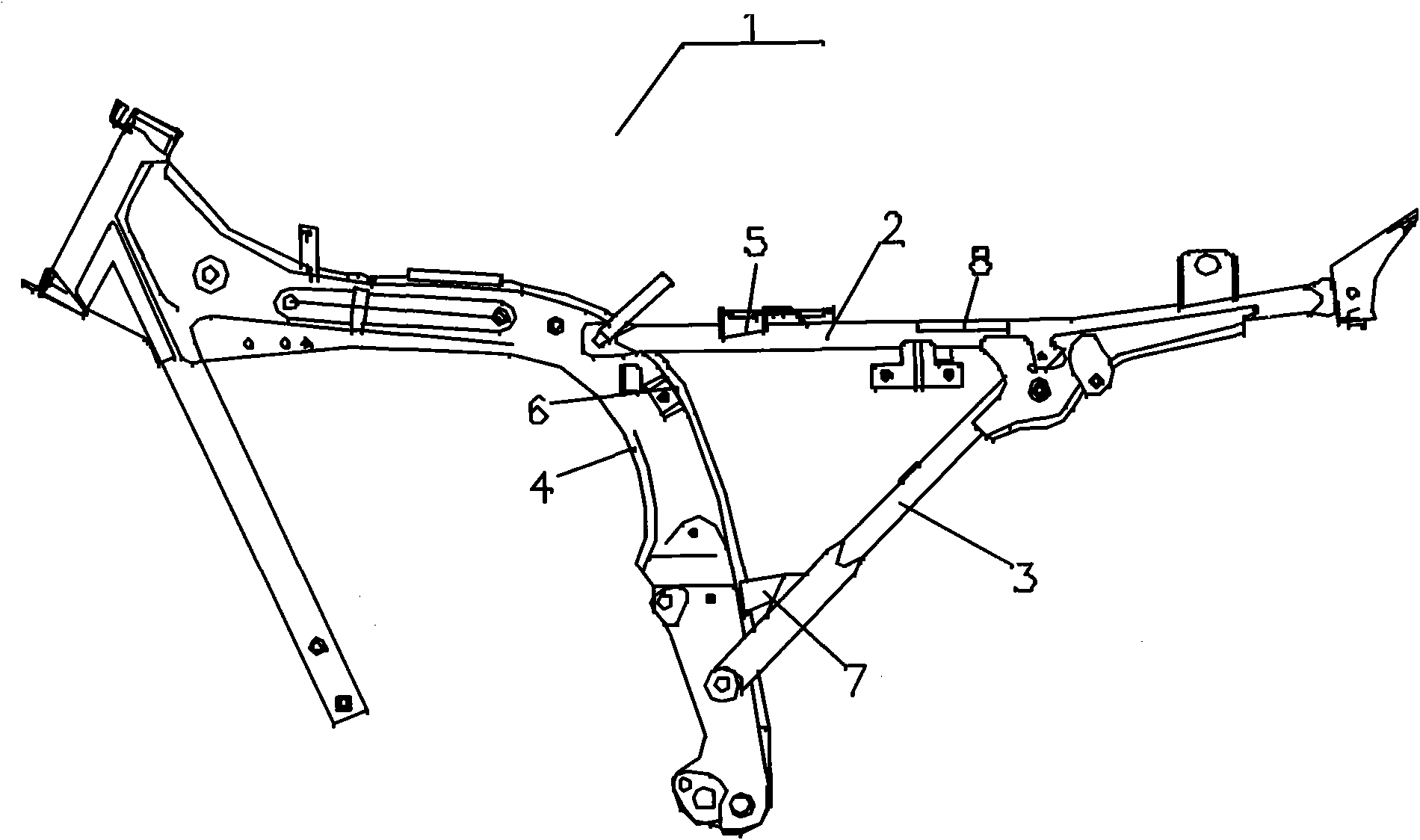

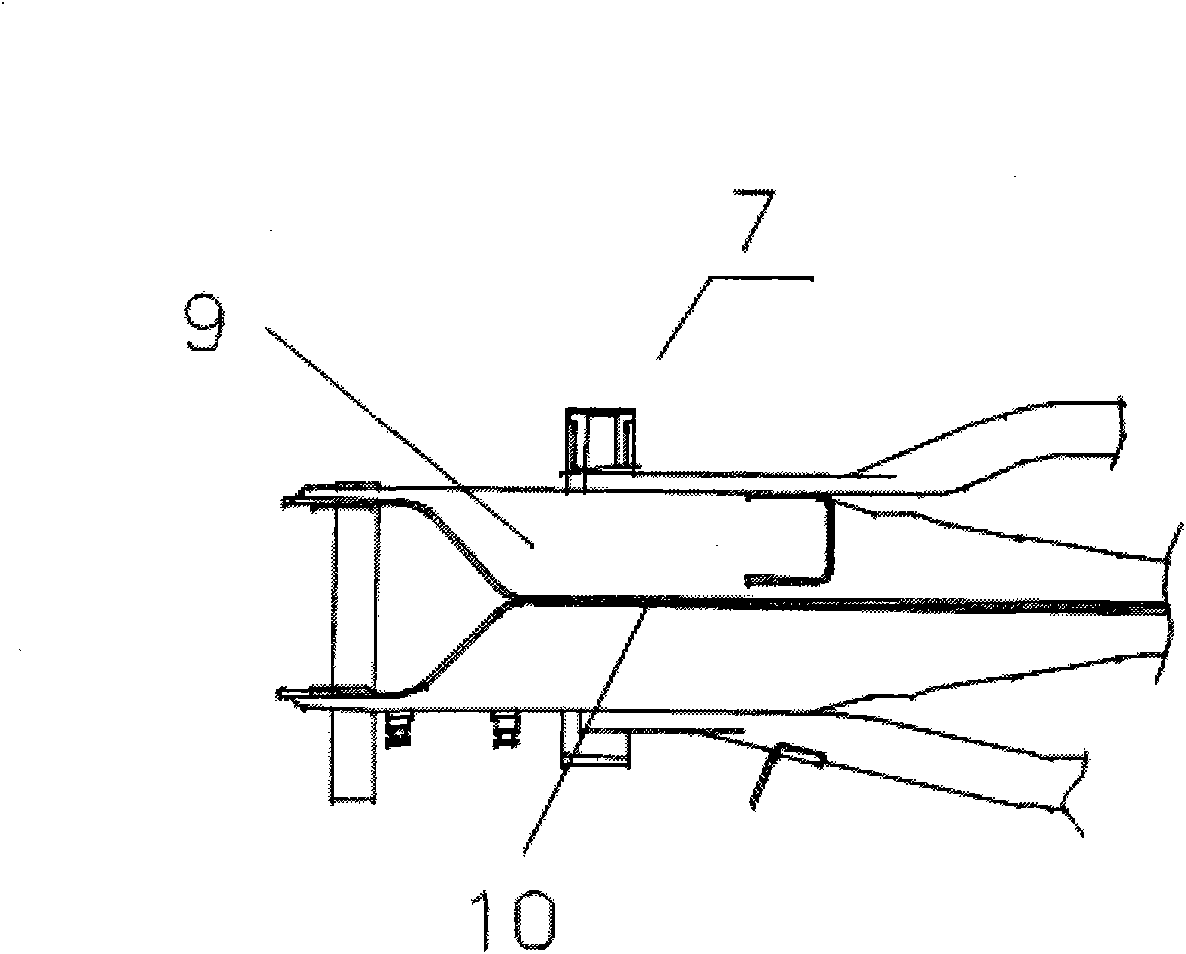

[0010] Preferably, a heavy-duty motorcycle frame 1, the frame 1 is arranged at the rear of the motorcycle, the frame 1 includes a beam tube 2, an inclined beam tube 3 and a beam tube 4; between the two beam tubes A first rib plate 5 is welded between them, a second rib plate 6 is welded between the two beam tubes, and a third rib plate 7 is welded between the inclined beam tube 3 and the beam tube 4 A casing 8 is sheathed on the beam pipe 2; the first ribs 5, 6, 7 are all provided with an inner hole 9, and the inner hole 9 is inserted with a liner 10.

[0011] Through the setting of the stiffener plate, the sleeve and the liner, the strength of the beam tube, the inclined beam tube and the beam tube is strengthened, and the strength of the vehicle frame is further strengthened, so that the Compared with the existing known technology, the invention h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com