Anti-drop cable hook for transfer conveyor

A loader and cable technology, which is applied to conveyors, earthwork drilling, transportation and packaging, etc., can solve the problems of cables falling off and affecting the normal operation of the loader, and achieve the effect of preventing cables from falling off and ensuring normal work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

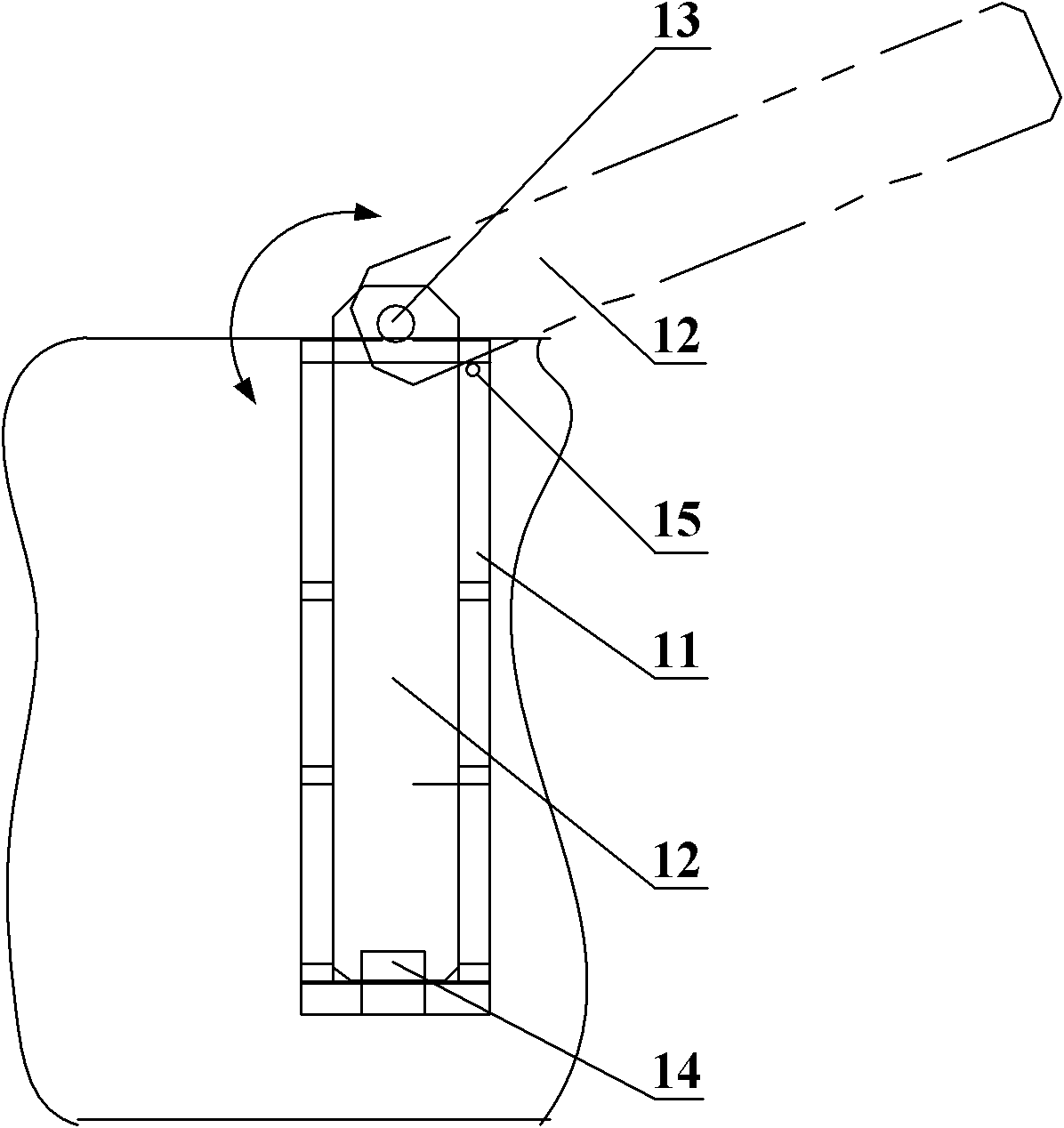

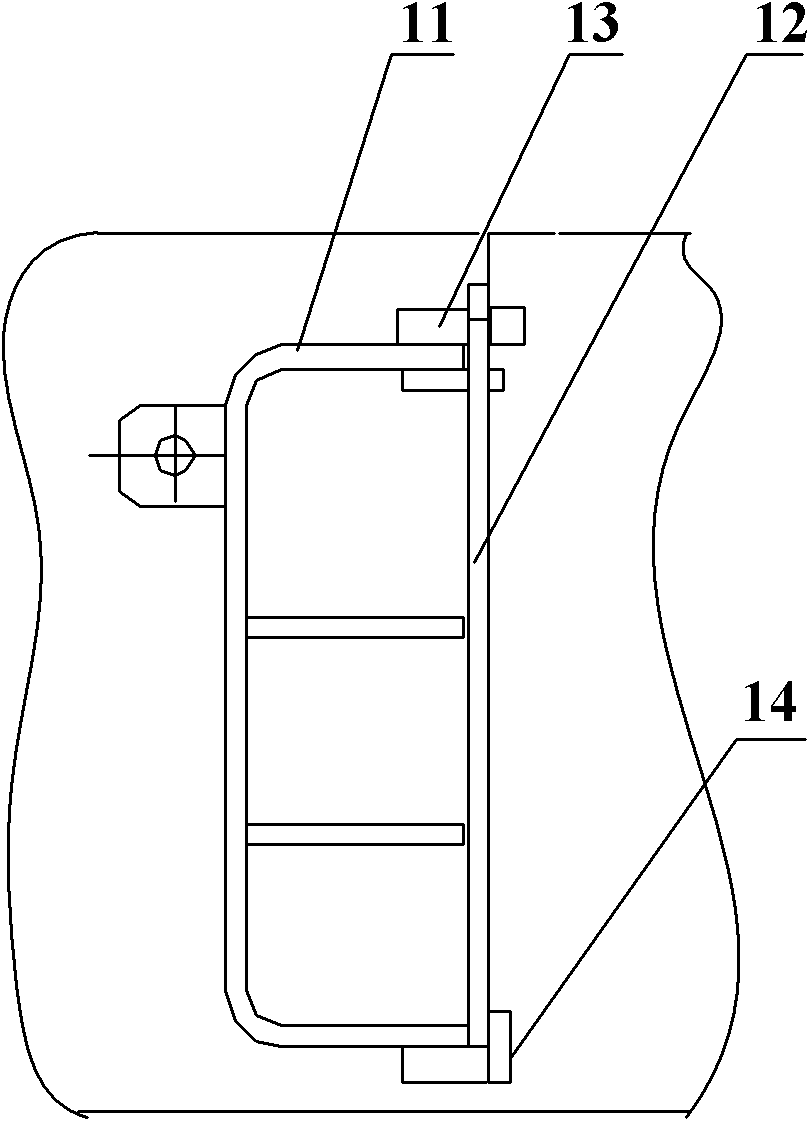

[0049] Please refer to figure 2 with image 3 As shown, the present invention provides a detachment-proof cable hook for the reloading machine 1, so as to prevent the cables wound on the reloading machine from falling off, so as to ensure the normal operation of the reloading machine. It includes: a cable hook frame 11, a shaft 13, a baffle plate 12 and a locking part 14, wherein the baffle plate 12 is hinged on the top plate of the cable hook frame 11 through the shaft 13, and can rotate on the plane where the baffle plate 12 is located; the baffle plate 12 A locking component 14 that resists the rotation of the baffle plate 12 is provided on it.

[0050] The above-mentioned shaft 13 is a swivel component that ensures that the baffle 12 rotates on its own plane, wherein one end of the shaft 13 is fixed to the cable hook frame 11, and the other end is hinged to the baffle 12, that is, the baffle 12 is provided with a through hole. The shaft 13 passes through the through hol...

Embodiment 2

[0056] For the anti-off cable hook on the reloading machine in the embodiment of the present invention, please refer to Figure 7 with 8 , comprising: a cable hook frame 21, two slide rails 23, a baffle plate 22 and a handle 22, wherein the two slide rails 23 are relatively arranged on the cable hook frame 21, and the two slide rails 23 and Figure 7 The direction shown by the middle arrow is parallel, and the slide rail 23 can be fixed on the cable hook frame 21 by bolts, or can be fixed on the cable hook frame 21 by welding; a handle 25 can also be set on the baffle plate 22, and the baffle plate can be moved 22 Move in the direction indicated by the arrow.

[0057] The above-mentioned detachment-proof cable hook used on the reloading machine can also be provided with a locking part 24 that resists the movement of the baffle plate 22 when it is placed at a predetermined position. The function of the locking part 24 prevents the baffle 22 from continuing to move when it mov...

Embodiment 3

[0060] For the anti-off cable hook of reloading machine 1 in the embodiment of the present invention, please refer to Figure 12 , including: a cable hook frame 31 and one end is fixed on the bottom plate of the cable hook frame 31, and the other end is detachably installed on the top plate of the cable hook frame 31 through a locking component 33. The locking part 33 is a pin shaft, and the pin shaft protrudes from the upper surface of the top plate of the cable hook frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com