A novel fixture capable of being used for fixing a leaky cable in a high-speed railway tunnel

A technology for leaking cables and high-speed railways, applied in the field of mechanical engineering, can solve the problems of low applicable speed and difficult use, and achieve the effect of preventing cables from falling off, high safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the technical content of the present invention, specific examples are given and described as follows in conjunction with the accompanying drawings.

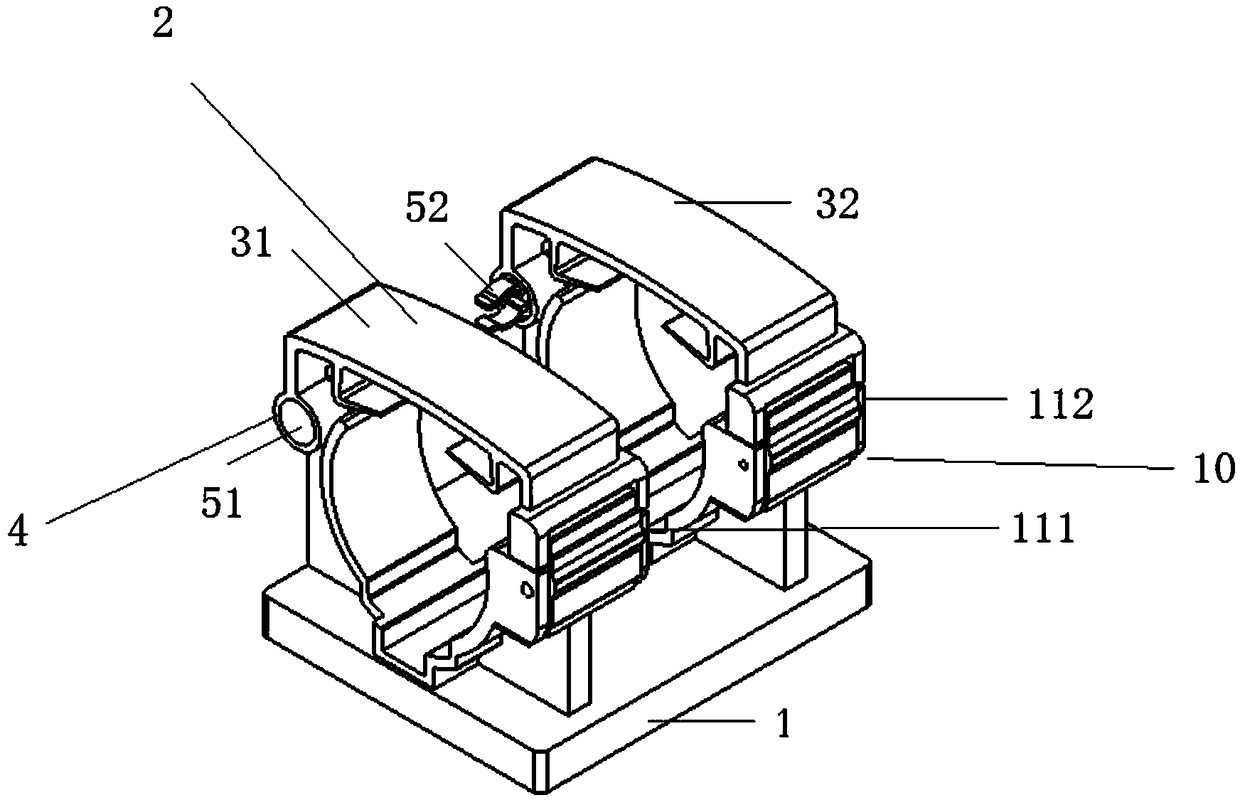

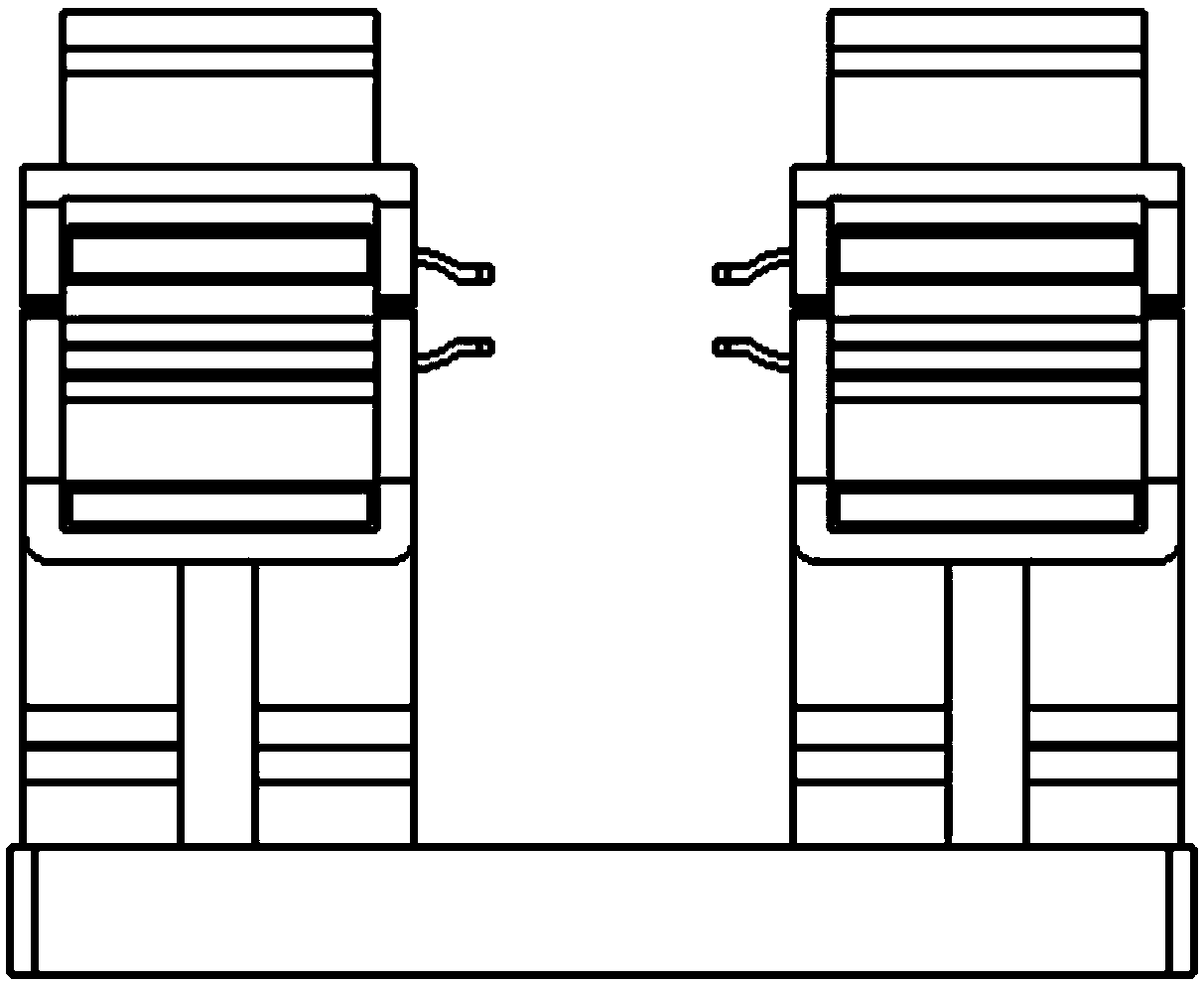

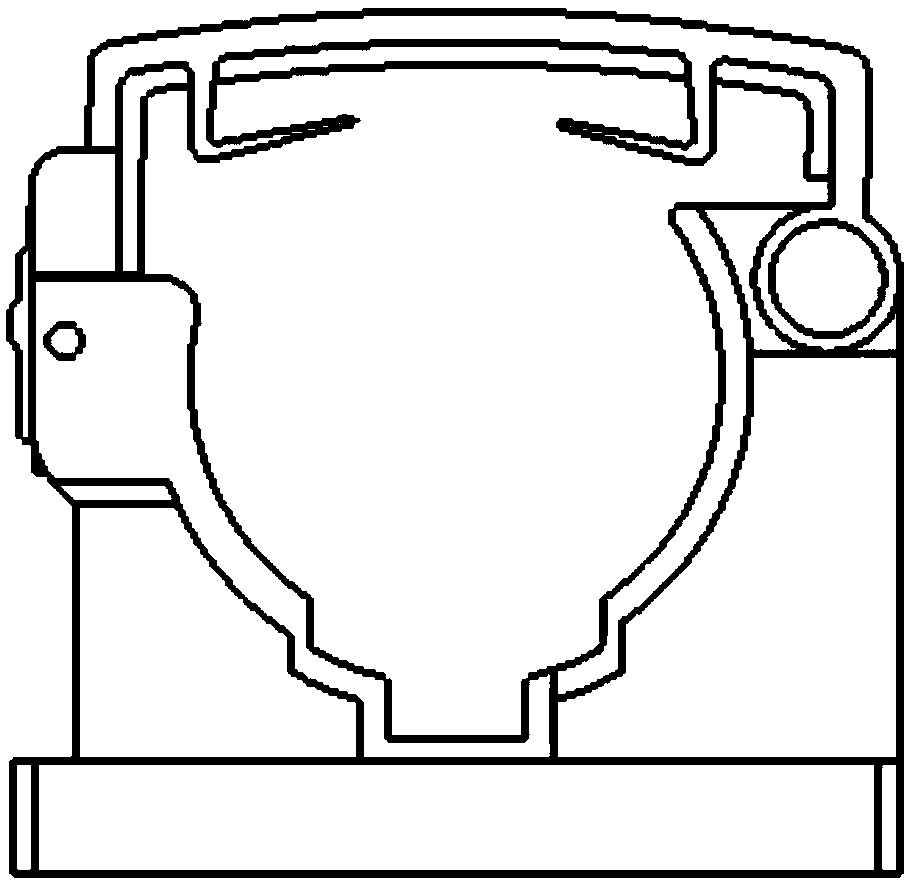

[0022] As shown in the figure above, the high-speed railway tunnel leakage cable fixing jig consists of a base 1 , a cover plate 2 , a rotating shaft 4 and a hook 10 . The cover plate and the base are connected by a rotating shaft one 51 and a rotating shaft two 52, a positioning spring 7 and a rotating shaft 6 are arranged in the hook, and a safety device 9 is arranged on the buckle plate 8 .

[0023] Among them, the base 1 is used to place the leakage cable; the pinch plate 8 cooperates with the cover plate 1 31 and the cover plate 2 32 to fix the cable; the positioning spring 7 keeps the pinch plate 8 in a buckled state, and the safety device passes through the Cooperate with the positioning block to prevent the clamp from being accidentally opened due to non-human factors.

[0024] Utiliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com