Cable support

A cable and horizontal support technology, which is applied in the direction of pipeline support, cable installation, ground cable installation, etc., can solve the problems of inability to adjust, inconvenient use, short service life, etc., and achieve neat and orderly arrangement of cables, prevent cables from falling off, The effect of strengthening firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

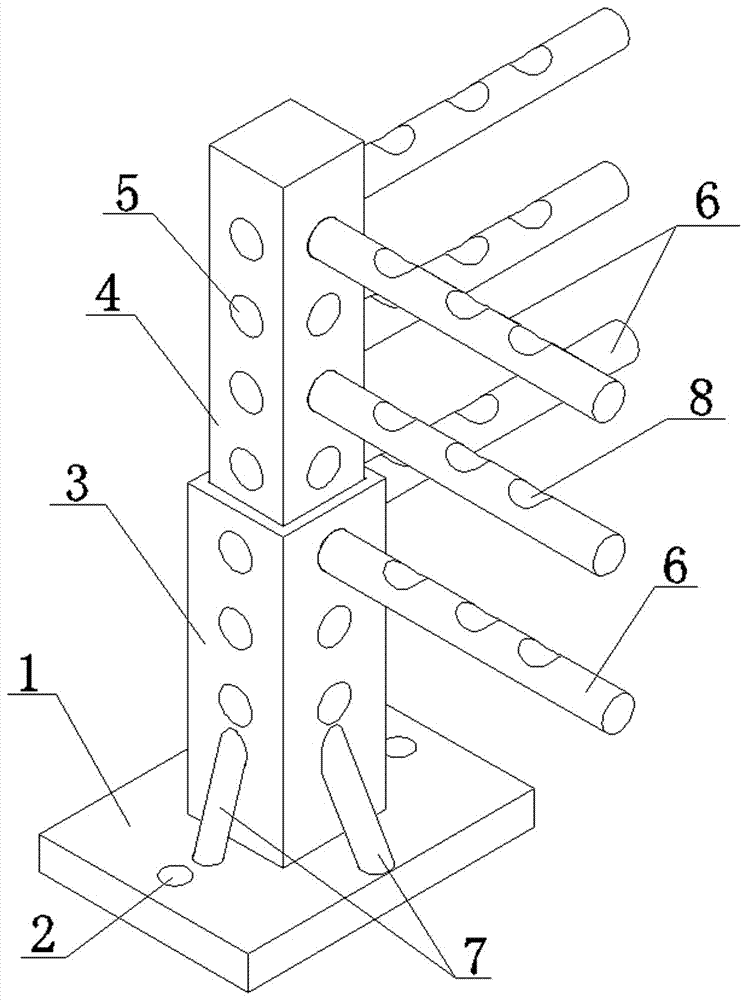

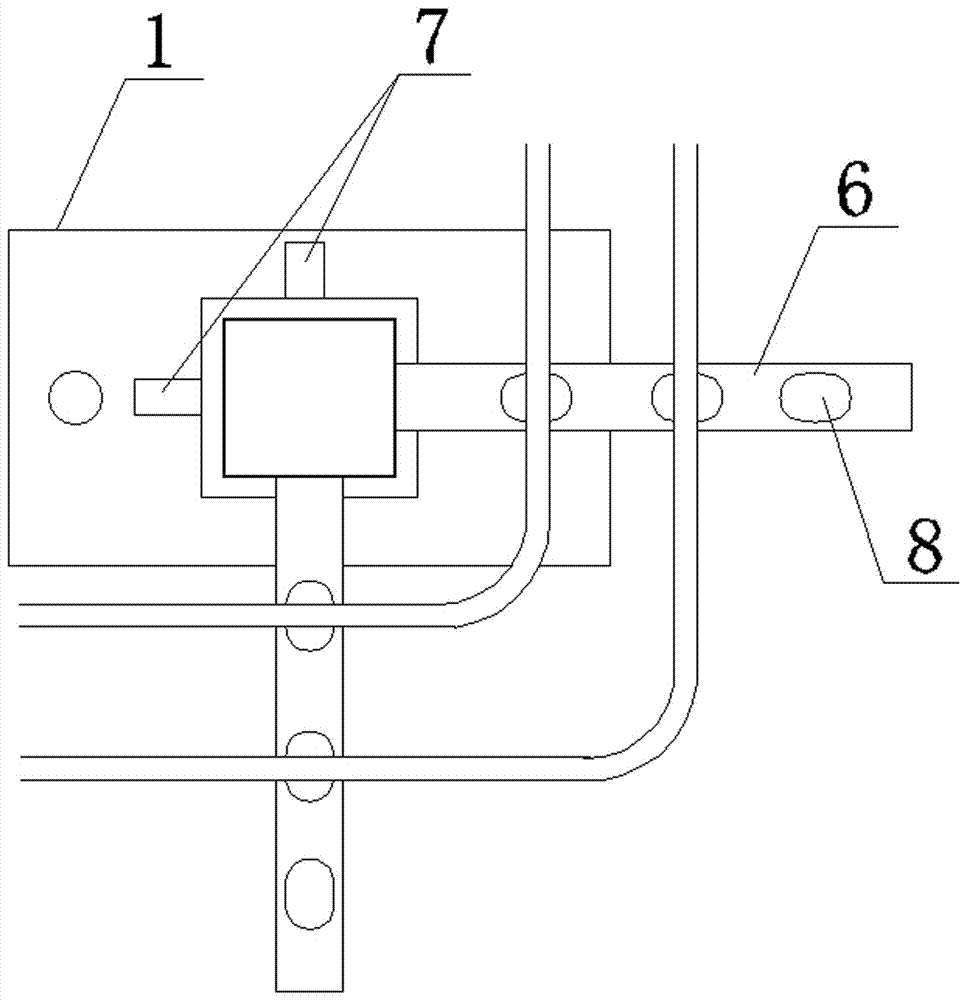

[0031] Such as figure 1 As shown, an adjustable cable special-shaped support includes a base 1, wherein the base 1 is provided with mounting holes 2 for installing the present invention on the bottom of the intersection of the cable trench, which can be fixed by bolts or welded. A support rod 3 is set in the center of the base 1, wherein the base and the support rod can be welded or plugged in. The present invention is welding, wherein the support rod 3 is a hollow tube with a square cross section, and the support rod 3 is inserted inside There is a movable rod 4, and a plurality of threaded holes 5 are sequentially arranged at the corresponding positions of the movable rod 4 and the support rod 3 from top to bottom, wherein the longitudinal distance between the threaded holes 5 can be set to 150-180 mm as required. In this embodiment It is set to 150mm; because there will be water in the bottom of the cable trench, the distance between the threaded hole 5 at the bottom of the...

Embodiment 2

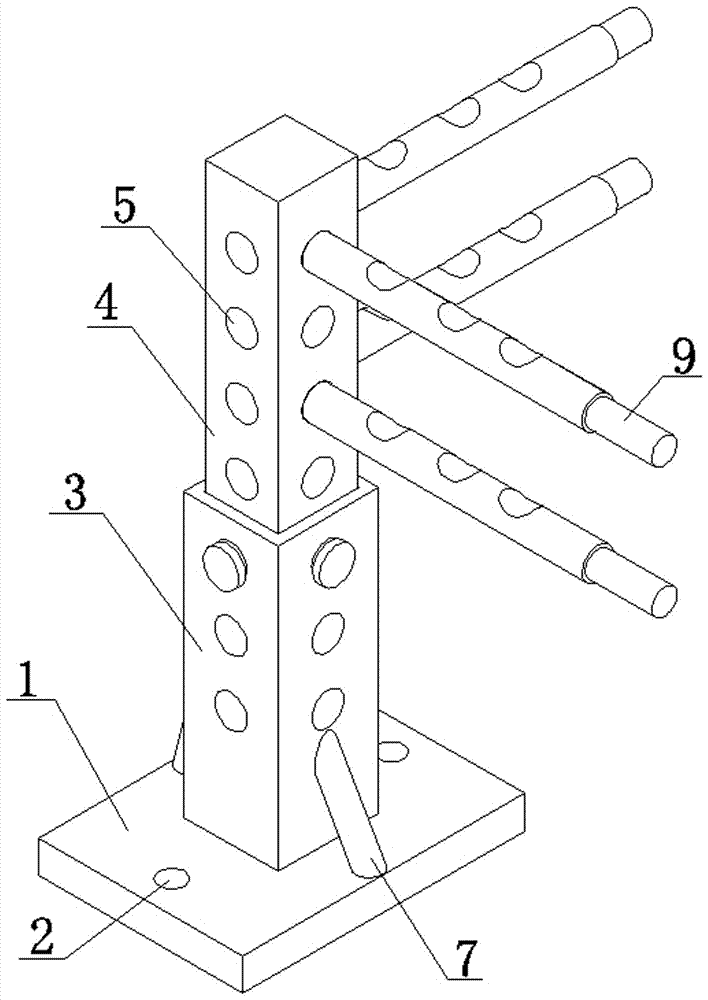

[0038] Embodiment 2 is basically the same structure as Embodiment 1, the difference is: as image 3 As shown, bolts are used between the support bar 3 and the movable bar 4, and the outer end of the cross bar 6 is hollow, and the inner thread is connected to the extension bar 9. When there are many cables and the width of the present invention is not enough, it can be extended by increasing Bar 9 increases the use width of the present invention, which is convenient and practical.

[0039] And the base 1, the support rod 3, the movable rod 4 and the horizontal support are all sprayed with waterproof and corrosion-resistant paint, wherein the waterproof and corrosion-resistant paint is made of the following raw materials in parts by weight: 32 parts of silicon acrylic emulsion, 11 parts of acrylic emulsion, silica sol 4 parts, 3.5 parts of titanium dioxide, 7 parts of ethylene glycol, 1.2 parts of sodium lauryl sulfate, 0.3 parts of dispersant, 5 parts of nano silicon carbide, 1...

Embodiment 3

[0042] Embodiment 3 is basically the same structure as Embodiment 2, the difference is: as Figure 4 As shown, the transverse support includes two transverse bars at the same level. In this embodiment, the two transverse bars 6 are horizontally arranged, and the threaded connection between the transverse bars 6 and the threaded holes 5. At this time, the direction of the cable is as follows: Figure 4 As shown, therefore the structure of the present invention can be adjusted according to the situation of the cable trench, which is very convenient and practical.

[0043] And the base 1, the support rod 3, the movable rod 4 and the horizontal support are all sprayed with waterproof and corrosion-resistant paint, wherein the waterproof and corrosion-resistant paint is made of the following raw materials in parts by weight: 34 parts of silicon acrylic emulsion, 10 parts of acrylic emulsion, silica sol 5 parts, 4 parts of titanium dioxide, 6 parts of ethylene glycol, 1.5 parts of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com