Degradable synthetic paper material and preparation method thereof

A technology for synthetic paper and plastic resin, applied in the field of plastic degradable synthetic paper material and its preparation, can solve the problems of difficult processing, poor dispersibility and the like, and achieve the effects of low cost, low cost and suitability for industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

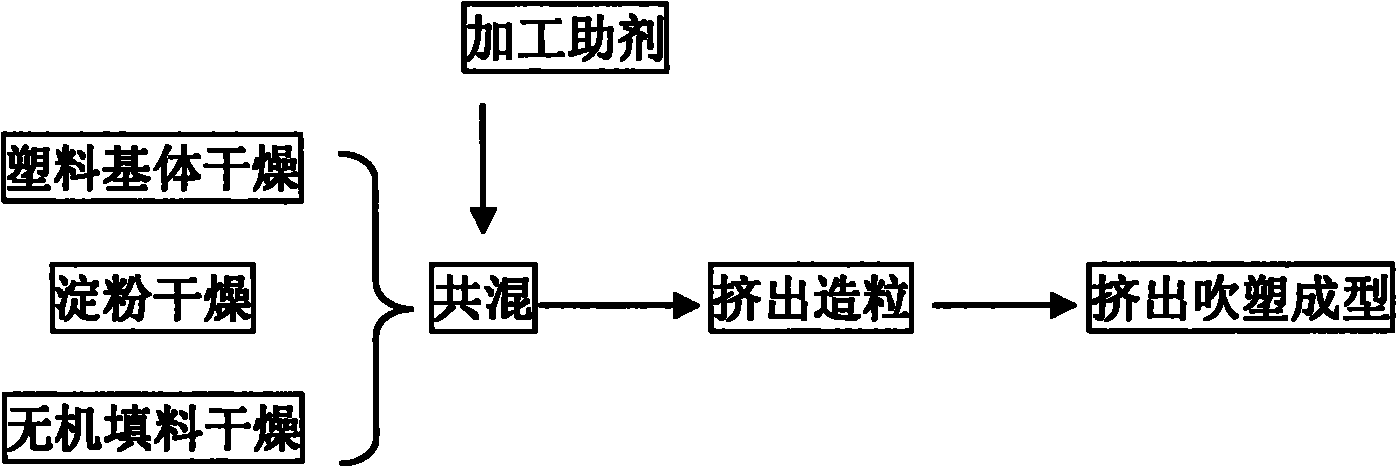

Method used

Image

Examples

Embodiment 1

[0031] Accurately weigh 75 parts of high-density polyethylene (produced by Sinopec Shanghai Jinshan Petrochemical Branch, model: MH602), 25 parts of low-density polyethylene (produced by Sinopec Shanghai Jinshan Petrochemical Branch, model: Q210), 225 parts of industrial grade starch , 100 parts of calcium carbonate (1500 mesh, heavy) dried and grafted with 15 parts of polyethylene-1-octene copolymer glycidyl methacrylate, 20 parts of ethylene vinyl acetate (EVA), 10 parts of poly Ethylene wax (PEW), 10 parts stearic acid (Hst), 10 parts ethylene bisstearamide (EBS), 10 parts vinyltris(β-methoxyethoxy)silane, in a high speed mixer After mixing evenly, put it into a twin-screw extruder to extrude and granulate. The temperature of each section of the extruder is set as (from the feed port to the die head): 100-140-160-180°C, the screw speed is 150rpm, feed The material rotation speed was 10 rpm. The obtained blend is dried at 90-100° C. and then extruded and blow-molded; the ob...

Embodiment 2

[0033] Accurately weigh 62.5 parts of high-density polyethylene (produced by Sinopec Shanghai Jinshan Petrochemical Branch, model: MH602), 37.5 parts of low-density polyethylene (produced by Sinopec Shanghai Jinshan Petrochemical Branch, model: Q210), 312.5 parts of industrial grade starch , 125 parts of calcium carbonate (1500 mesh, heavy) dried and grafted with 18.75 parts of polyethylene-1-octene copolymer glycidyl methacrylate, 25 parts of ethylene vinyl acetate (EVA), 12.5 parts of poly Ethylene wax (PEW), 12.5 parts stearic acid (Hst), 12.5 parts ethylene bisstearamide (EBS), 12.5 parts vinyltris(β-methoxyethoxy)silane, in a high speed mixer After mixing evenly, put it into a twin-screw extruder to extrude and granulate. The temperature of each section of the extruder is set as (from the feed port to the die head): 100-140-160-180°C, the screw speed is 150rpm, feed The material rotation speed was 10 rpm. The obtained blend is dried at 90-100° C. and then extruded and bl...

Embodiment 3

[0035] Accurately weigh 71.4 parts of high-density polyethylene (produced by Sinopec Shanghai Jinshan Petrochemical Branch, model: MH602), 28.6 parts of low-density polyethylene (produced by Sinopec Shanghai Jinshan Petrochemical Branch, model: Q210), 464.3 parts of industrial grade starch , 71.4 parts of calcium carbonate (1500 mesh, heavy) dried and grafted with 14.3 parts of polyethylene-1-octene copolymer glycidyl methacrylate, 21.4 parts of ethylene vinyl acetate (EVA), 7.15 parts of poly Ethylene wax (PEW), 14.3 parts stearic acid (Hst), 14.3 parts ethylene bisstearamide (EBS), 7.15 parts vinyltris(β-methoxyethoxy)silane, in a high speed mixer After mixing evenly, put it into a twin-screw extruder to extrude and granulate. The temperature of each section of the extruder is set as (from the feed port to the die head): 100-140-160-180°C, the screw speed is 150rpm, feed The material rotation speed was 10 rpm. The obtained blend is dried at 90-100° C. and then extruded and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com