Transmission device of automatic round-surface screen printing machine

A technology of transmission device and screen printing machine, which is applied in the field of machinery, can solve the problems of large impact force of transmission shaft and sprocket, waste of manpower and material resources, and large pollution of transmission system, so as to achieve large transmission torque, high efficiency and high transmission stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

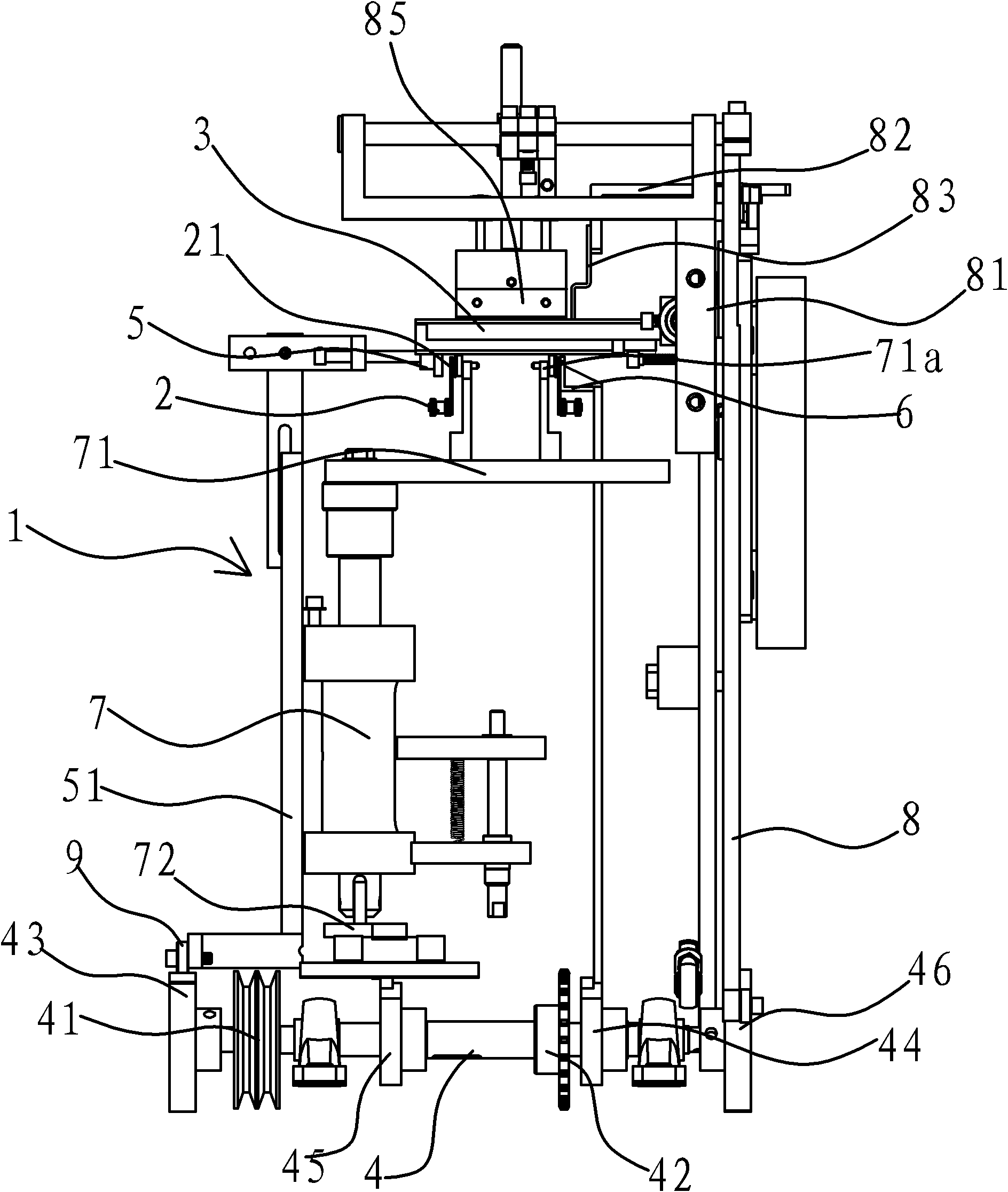

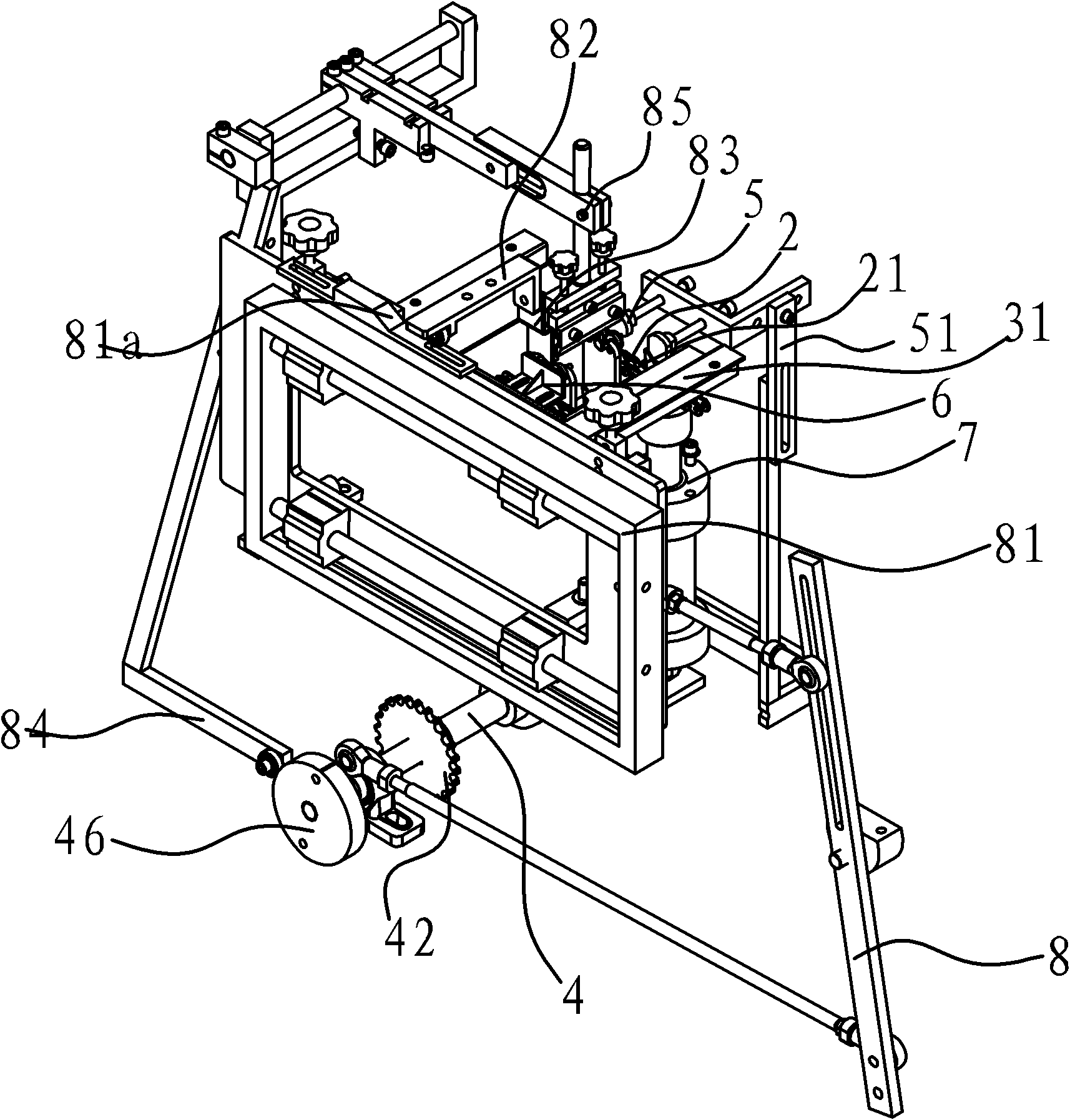

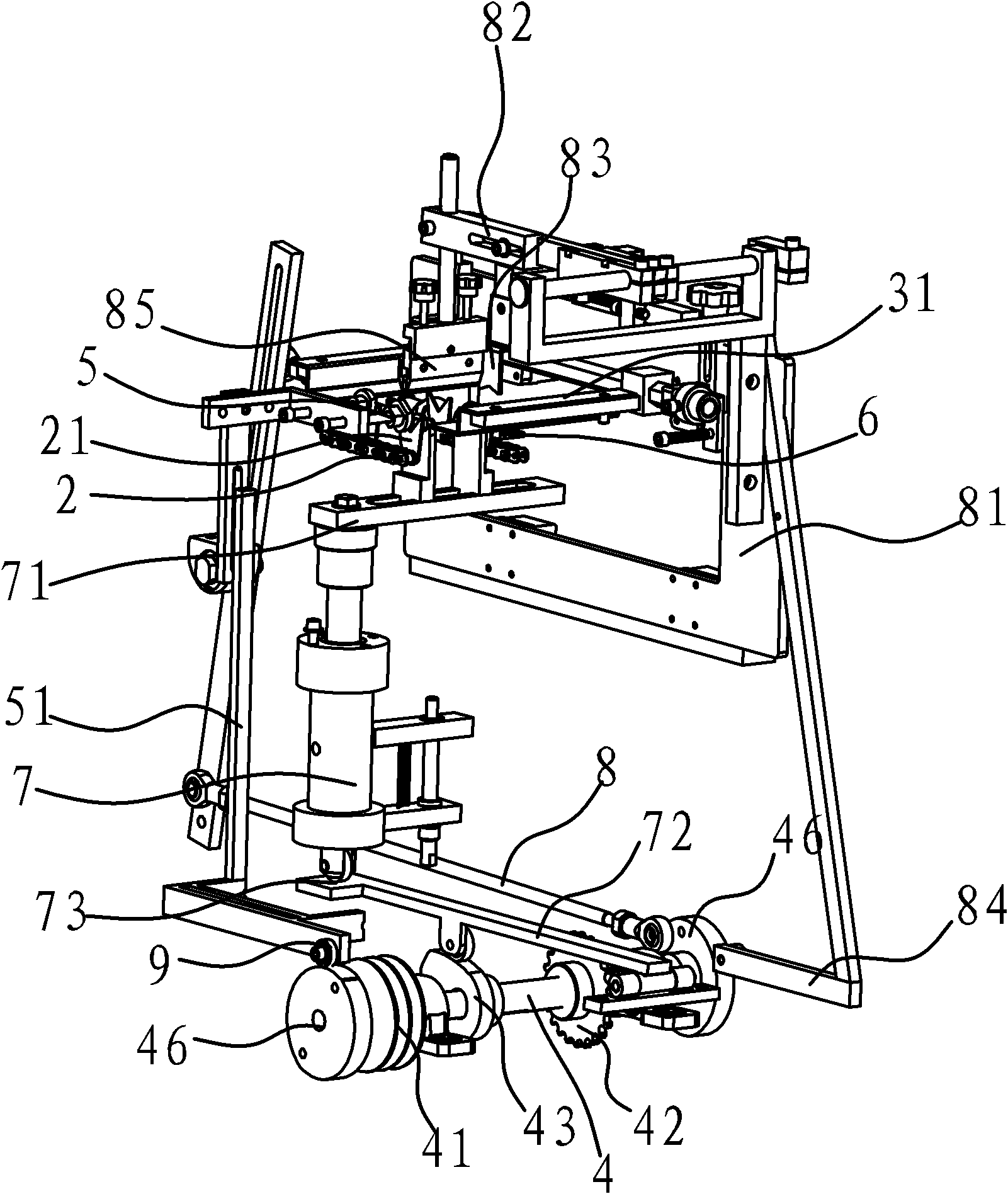

[0042] Such as Figure 1~3 As shown, the automatic circular screen printing machine includes a frame 1, the two ends of the frame 1 are provided with a main sprocket and a secondary sprocket, and the main sprocket and the secondary sprocket are nested with a conveyor chain 2 for transferring workpieces. 2 is provided with a bracket 21 for supporting workpieces, and above the conveyor chain 2 is provided with silk screen ink cartridges 3 for printing workpieces. 3 and carry out the jacking seat 71 of printing.

[0043] The working principle of the automatic round surface screen printing machine is as follows: the intermittent movement of the conveyor chain 2 drives the workpiece on the support 21 to move intermittently. P...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap