Phase change material capsule and preparation method thereof

A technology of phase change materials and capsules, applied in the field of phase change materials, to achieve the effects of eliminating supercooled crystallization, convenient operation, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

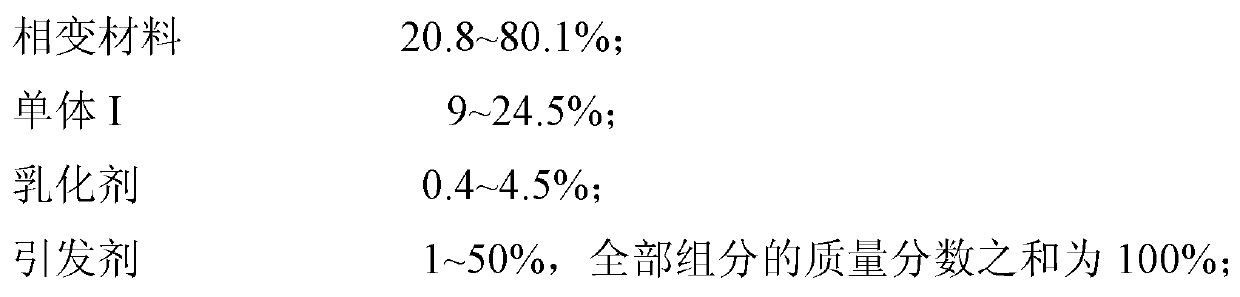

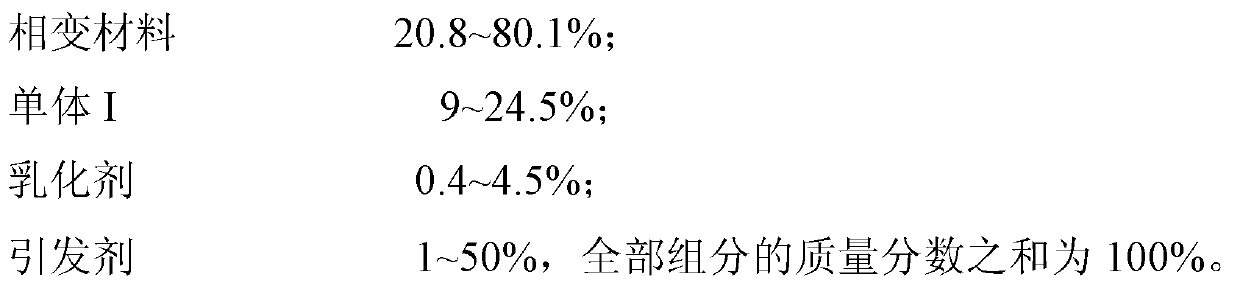

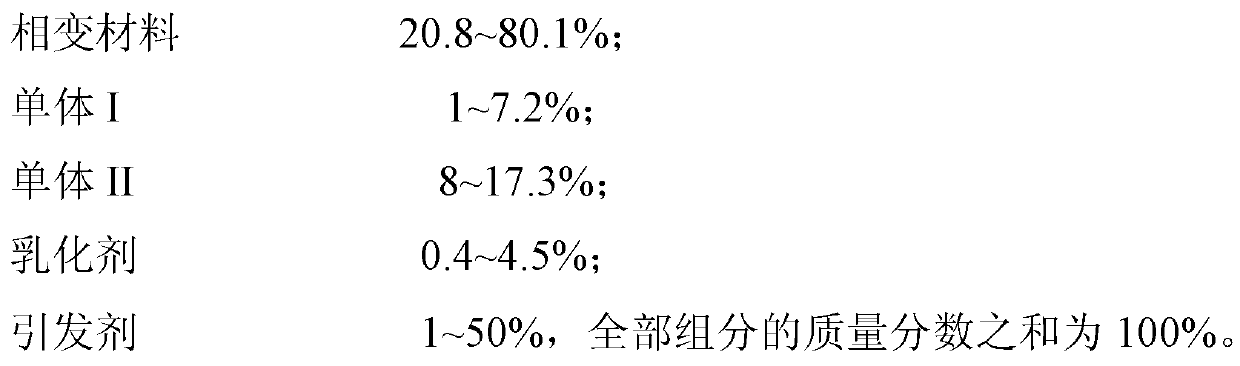

[0033] The present invention simultaneously designs the preparation method (abbreviation preparation method) of phase-change material capsule, and this preparation method adopts the mass composition of capsule described in the present invention and following technology: take polymerized monomer as capsule wall material, take phase-change material as capsule core The mass fraction of the polymerized monomer, phase change material, emulsifier, initiator, and dispersant mixture is mechanically stirred or ultrasonically oscillated at a temperature of 0 to 90 ° C, and the optical microscope or environmental scanning electron microscope is used at any time Observe the particle size of the emulsion droplet in the emulsion until an emulsion with a particle size of 1-1000 microns or below 1 micron is produced, and then under the action of an initiator, the monomer is polymerized by suspension polymerization or in-situ polymerization , maintained at a stirring speed of 100-999r / min for 1...

Embodiment 1

[0046] At 0°C, 1 g of 3-eicosylpyrrole, 17.3 g of pyrrole, 30 g of a saturated aqueous solution of calcium chloride, 49.9 g of ferric bromide, 380 g of chloroform and 10 g of emulsifier polyacrylic acid sodium salt emulsion (solid content 1.8 g) were prepared in 500mW ultrasonic vibration for 1 hour, so that the average diameter of the emulsion droplets reaches 0.7 microns; then stir at 800rpm for 5 hours; stop stirring, and obtain the phase change material nanocapsule emulsion.

[0047] After testing, the average particle diameter of the obtained nanocapsules is 0.9 micron, and the crystallization melting endothermic temperature (T m ) is 29.9°C, the heat of fusion (ΔH m ) is 64J / g, crystallization exothermic temperature (T c ) is 26.1°C, there is no obvious supercooling crystallization phenomenon, and the crystallization enthalpy (ΔH c ) is 65J / g, the mass percent of calcium chloride in the nanocapsule is 30%, and the conductivity of the nanocapsule is 980S / cm.

Embodiment 2

[0049] Under 0 ℃, 3-decyl pyrrole 7.2g, pyrrole 8g, sodium sulfate saturated aqueous solution 31.8g, copper bromide 50g, carbon tetrachloride 300g and emulsifier styrene-maleic anhydride sodium salt emulsion 16g (solid content 3g), oscillating with ultrasonic wave at 500mW for 1 hour, so that the average diameter of the emulsion droplets reaches 0.6 micron; stirring at 800rpm for 5 hours; stopping stirring, to obtain phase change material nanocapsule emulsion.

[0050] After testing, the average particle size of the obtained nanocapsules is 0.8 microns, T m 32.4°C, ΔH m 54J / g, T c 29.1℃, no obvious supercooling crystallization phenomenon, ΔH c 55J / g, the mass percentage of sodium sulfate decahydrate in the nanocapsule is 56%, and the conductivity of the nanocapsule is 870S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com