Heat storage temperature regulation fiber and preparation method thereof

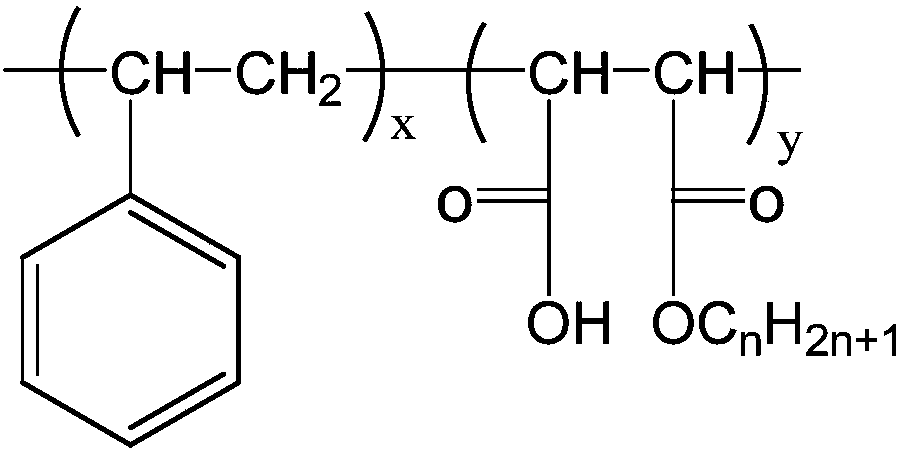

A heat storage and temperature regulation and fiber technology, which is applied in fiber processing, conjugated synthetic polymer rayon, filament/thread forming, etc. Reduce the application value and other problems to achieve the effect of ensuring continuity, eliminating supercooled crystallization and good interface compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

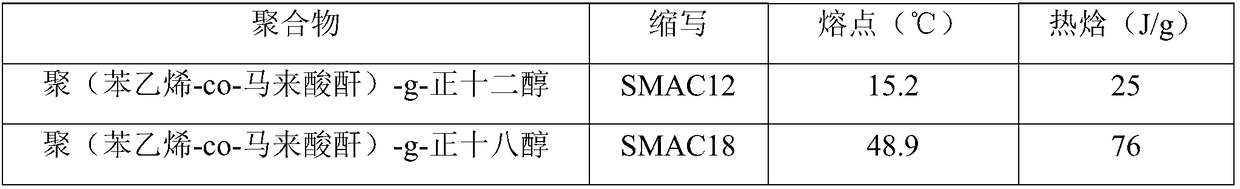

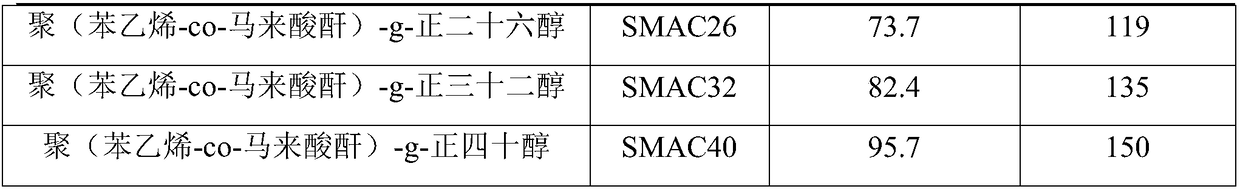

Method used

Image

Examples

Embodiment 1

[0031] Poly(styrene-co-maleic anhydride)-g-n-octadecyl alcohol with a grafting degree of 50% is used as a comb-shaped polymer phase change material, and polyethylene terephthalate with a melting temperature of 240°C Alcohol ester (PET, intrinsic viscosity 0.58) is a fiber-forming polymer. After drying to a moisture content of less than 50ppm, the mass ratio of the comb-like polymer phase change material to the fiber-forming polymer is controlled to be 40:60, at 250°C Melt compound spinning is made into concentric circular primary fibers, which are further processed into elastic yarns after being twisted by 1.5 times of drafting and 50 twists / 10cm12s, shaped and dried, and processed into long fibers.

[0032] After inspection, the fineness of the short fiber obtained in this embodiment is 1.9dtex, the tensile breaking strength is 3.5cN / dtex, and the elongation at break is 20%; the endothermic temperature of the fiber is 49.3°C, the heat absorption is 38J / g, and the heat release ...

Embodiment 2

[0034]Random copolymerization with poly(styrene-co-maleic anhydride)-g-n-octadecyl alcohol / n-tetradecyl alcohol (the molar ratio of n-stearyl alcohol and n-tetradecyl alcohol is 50:50) Comb-shaped polymer phase change material (grafting degree: 47%) is used as fiber, and polypropylene (melt index: 35g / 10min) is used as fiber-forming polymer. The mass ratio of the phase change material and the fiber-forming polymer is 50:50, and the sea-island type primary fiber is produced by melt composite spinning at 250°C, and further processed into elastic yarn after being twisted by 1.5 times drafting and 50 twists / 10cm12s.

[0035] After inspection, the fineness of the stretch yarn obtained in this embodiment is 80dtex / 48f, the tensile breaking strength is 2.8cN / dtex, and the elongation at break is 25%; The heat temperature is 34°C, and the heat release is 31J / g; the temperature of 5% thermal weight loss is 245°C; after extraction with cyclohexane as solvent, the mass loss rate of the fi...

Embodiment 3

[0037] Poly(styrene-co-maleic anhydride)-g-n-hexacosanol with a grafting degree of 48% is used as a comb-shaped polymer phase change material, and polycaprolactam (intrinsic viscosity number 0.65) is used as a fiber-forming polymer After the material is dried until the moisture is lower than 50ppm, the mass ratio of the comb-shaped polymer phase change material and the fiber-forming polymer is controlled to be 40:60, and the concentric circular primary fiber is made by melt composite spinning at 260 °C, and further passed 1.5 times drafting, 50 twists / 10cm12s twisting, processed into stretch yarn, shaped and dried, processed into long fibers.

[0038] After inspection, the fineness of the short fiber obtained in this embodiment is 3.2dtex, the tensile breaking strength is 3.3cN / dtex, and the elongation at break is 26%; the endothermic temperature of the fiber is 74°C, the heat absorption is 53J / g, and the heat release The temperature is 62°C, the heat release is 56J / g; the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| endothermic temperature | aaaaa | aaaaa |

| heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com