Heat storage and temperature regulation fiber and its preparation method

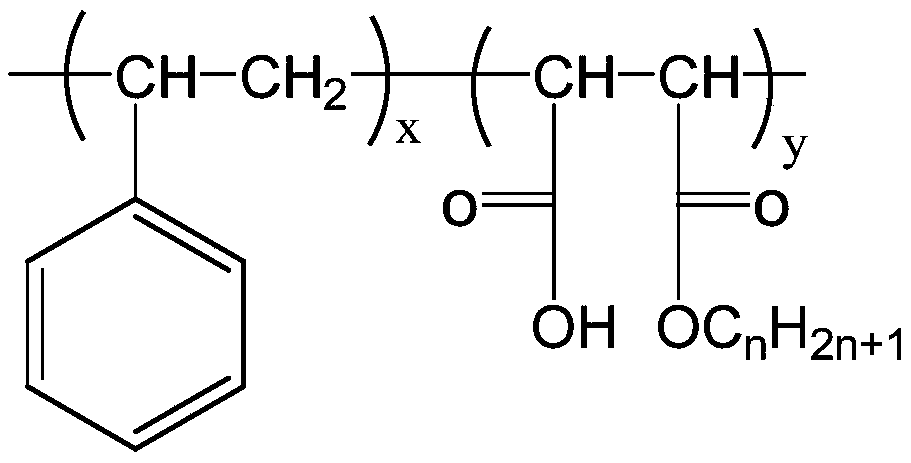

A technology of heat storage and temperature regulation and fiber, which is applied in fiber processing, filament/thread forming, textiles and papermaking, etc. It can solve the problems of low heat storage, reduced application value, low proportion of energy storage and temperature regulation fiber phase change materials, etc. , to achieve the effect of ensuring continuity, good interfacial compatibility, and eliminating supercooled crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

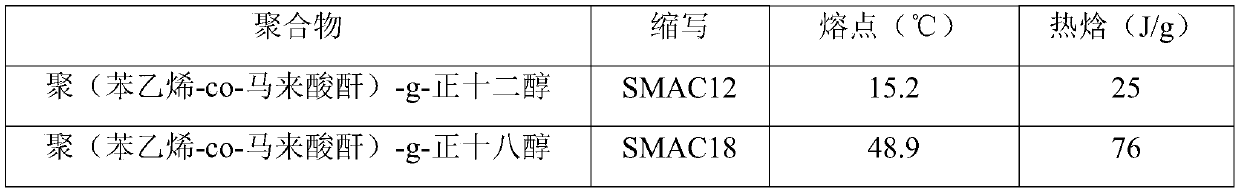

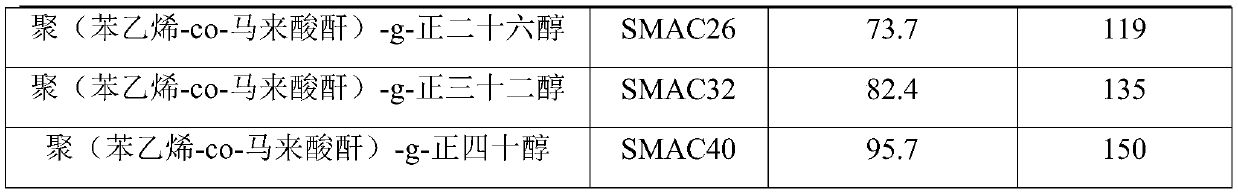

[0031] Poly(styrene-co-maleic anhydride)-g-n-octadecyl alcohol with a grafting degree of 50% is used as a comb-shaped polymer phase change material, and polyethylene terephthalate with a melting temperature of 240°C Alcohol ester (PET, intrinsic viscosity 0.58) is a fiber-forming polymer. After drying to a moisture content of less than 50ppm, the mass ratio of the comb-like polymer phase change material to the fiber-forming polymer is controlled to be 40:60, at 250°C Melt compound spinning is made into concentric circular primary fibers, which are further processed into elastic yarns after being twisted by 1.5 times of drafting and 50 twists / 10cm12s, shaped and dried, and processed into long fibers.

[0032] After inspection, the fineness of the short fiber obtained in this embodiment is 1.9dtex, the tensile breaking strength is 3.5cN / dtex, and the elongation at break is 20%; the endothermic temperature of the fiber is 49.3°C, the heat absorption is 38J / g, and the heat release ...

Embodiment 2

[0034]Random copolymerization with poly(styrene-co-maleic anhydride)-g-n-octadecyl alcohol / n-tetradecyl alcohol (the molar ratio of n-stearyl alcohol and n-tetradecyl alcohol is 50:50) Comb-shaped polymer phase change material (grafting degree: 47%) is used as fiber, and polypropylene (melt index: 35g / 10min) is used as fiber-forming polymer. The mass ratio of the phase change material and the fiber-forming polymer is 50:50, and the sea-island type primary fiber is produced by melt composite spinning at 250°C, and further processed into elastic yarn after being twisted by 1.5 times drafting and 50 twists / 10cm12s.

[0035] After inspection, the fineness of the stretch yarn obtained in this embodiment is 80dtex / 48f, the tensile breaking strength is 2.8cN / dtex, and the elongation at break is 25%; The heat temperature is 34°C, and the heat release is 31J / g; the temperature of 5% thermal weight loss is 245°C; after extraction with cyclohexane as solvent, the mass loss rate of the fi...

Embodiment 3

[0037] Poly(styrene-co-maleic anhydride)-g-n-hexacosanol with a grafting degree of 48% is used as a comb-shaped polymer phase change material, and polycaprolactam (intrinsic viscosity number 0.65) is used as a fiber-forming polymer After the material is dried until the moisture is lower than 50ppm, the mass ratio of the comb-shaped polymer phase change material and the fiber-forming polymer is controlled to be 40:60, and the concentric circular primary fiber is made by melt composite spinning at 260 °C, and further passed 1.5 times drafting, 50 twists / 10cm12s twisting, processed into stretch yarn, shaped and dried, processed into long fibers.

[0038] After inspection, the fineness of the short fiber obtained in this embodiment is 3.2dtex, the tensile breaking strength is 3.3cN / dtex, and the elongation at break is 26%; the endothermic temperature of the fiber is 74°C, the heat absorption is 53J / g, and the heat release The temperature is 62°C, the heat release is 56J / g; the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| endothermic temperature | aaaaa | aaaaa |

| heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com