Adjustable leveling stool and method for controlling floorslab thickness by using same

An adjustable and flat stool technology, which is applied in the processing of building materials, construction, building construction, etc., can solve difficult problems and achieve the effect of simple operation, low processing cost and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

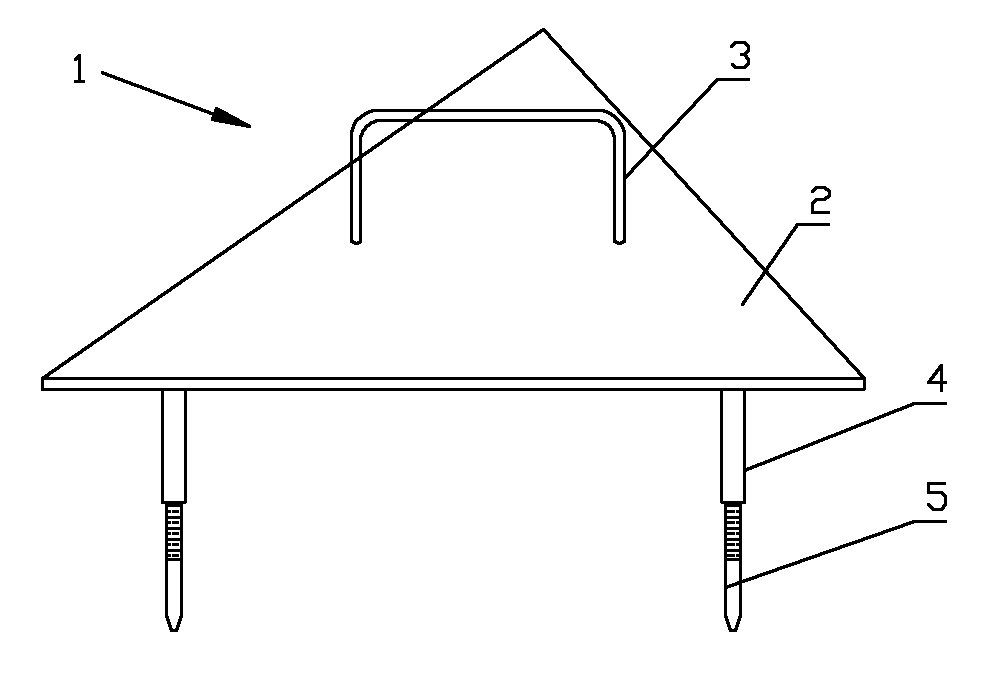

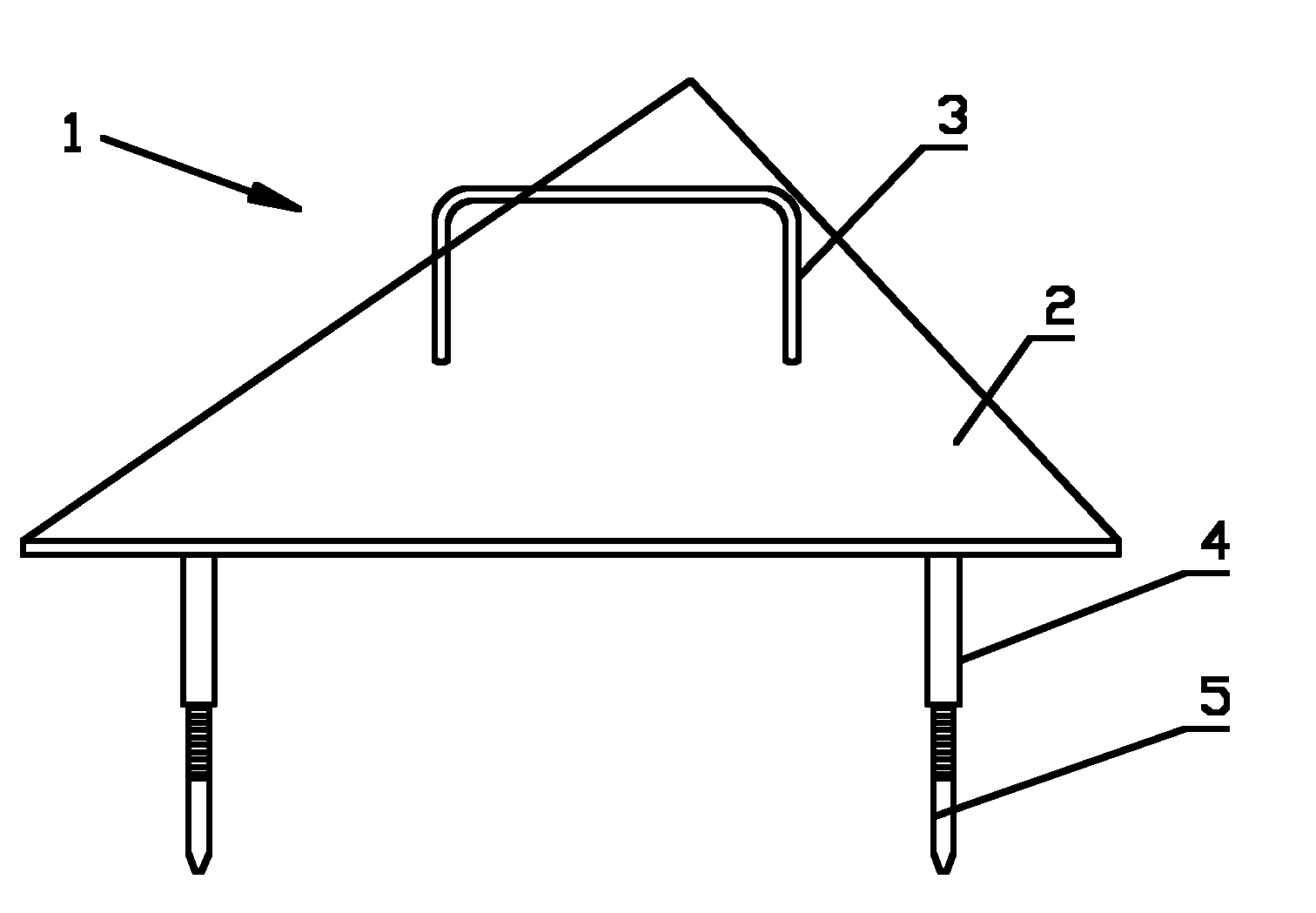

[0013] Such as figure 1 As shown, it is an embodiment of the adjustable leveling stool of the present invention, including a flat plate 2, a handle 3 is provided on the upper plane of the flat plate, and three telescopic support feet are provided on the lower plane of the flat plate. The flat plate 2 is a triangular steel plate, and the three telescopic support legs are arranged below three corners of the triangular steel plate. The supporting foot comprises a sleeve 4 provided with an internal thread, and a threaded steel bar head 5 threaded in the sleeve.

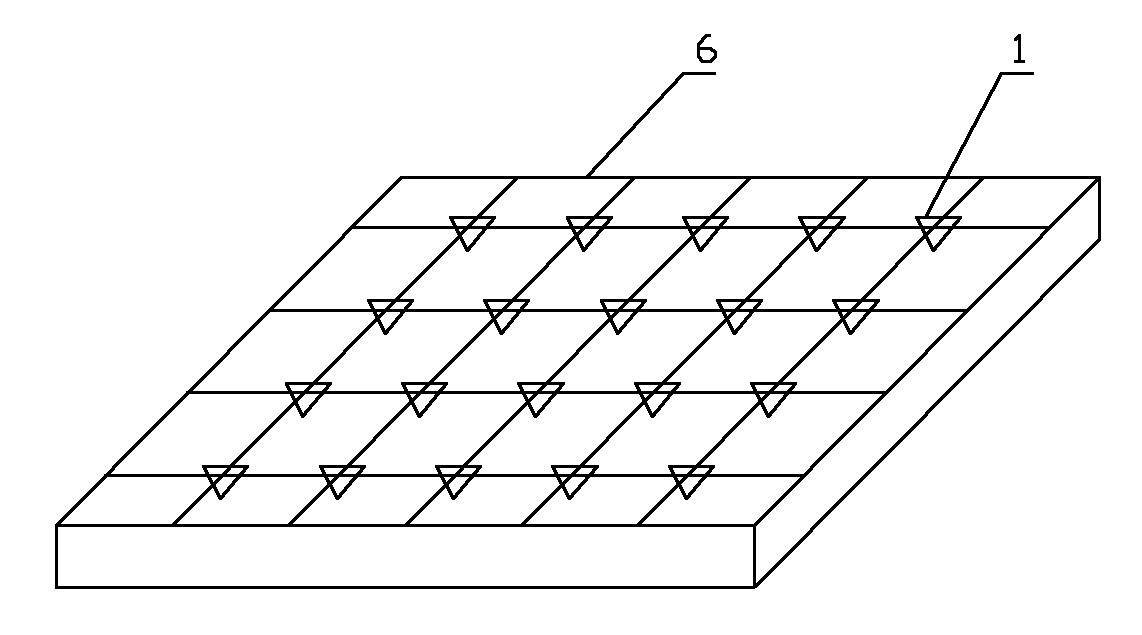

[0014] Such as figure 2 As shown, when in use, first adjust the length of the legs according to the thickness of the floor so that the length of the legs equals the thickness of the floor, then place the adjustable leveling stool 1 on the floor template 6, and control the height of the floor according to the point-line-surface control method. Thickness, that is, to control a plane through one point and one line. The sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com