Valve bank structure for refrigeration compressor

A technology of refrigeration compressors and valve groups, which is applied in the direction of mechanical equipment, machines/engines, liquid variable displacement machines, etc. It can solve the problems of high manufacturing cost, large number of parts, complex structure, etc., and achieve obvious manufacturing cost. Simplify, reduce obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

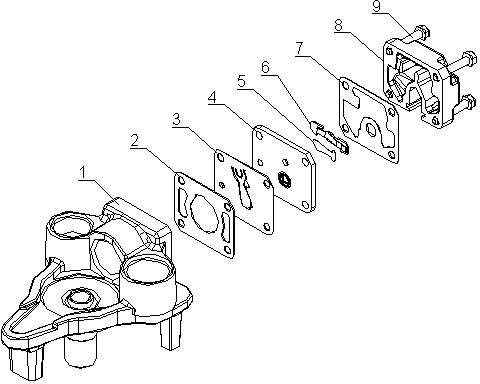

[0016] like Figure 4 As shown, the valve group structure of the refrigeration compressor of the present invention includes a valve plate gasket 12 , a suction valve plate 13 , a valve plate 14 , an exhaust valve plate 15 , a limit seal 16 , a cylinder head 17 and a retaining spring 18 .

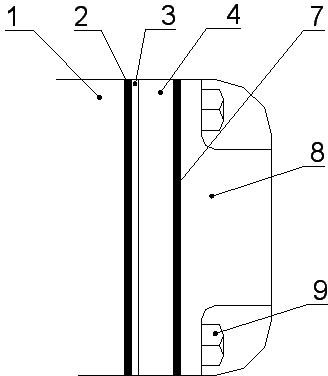

[0017] like Figure 5 As shown, the valve block structure of the refrigeration compressor of the present invention is fixed by the snap ring 18 and the crankcase 11, the crankcase 11 is provided with a snap ring groove 20, the snap ring 18 is provided with a claw 19, and the claw 19 snaps into the snap ring groove After 20, the elastic deformation of the jumper 18 occurs, and the elastic force generated after the deformation of the jumper 18 ensures that the valve group structure is in a compressed state.

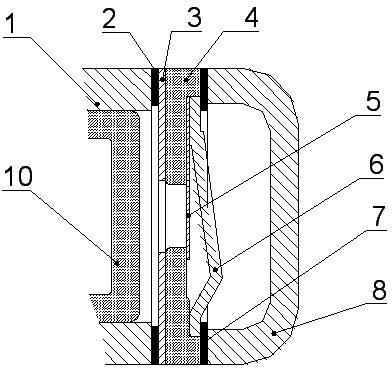

[0018] like Figure 6 and Figure 7 As shown, the valve plate 14 is provided with a groove 22 for installing the exhaust valve plate 15; the limit seal 16 is provided with a limit prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com