Quantitative grease injection device for automobile sunvisor rotating mechanism

A technology of automobile sun visor and rotating mechanism, which is applied to quantitative devices, engine lubrication, engine components, etc., can solve the problems of poor rotation durability, low yield and high noise, and achieves lower production costs and better rotation durability. , the effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

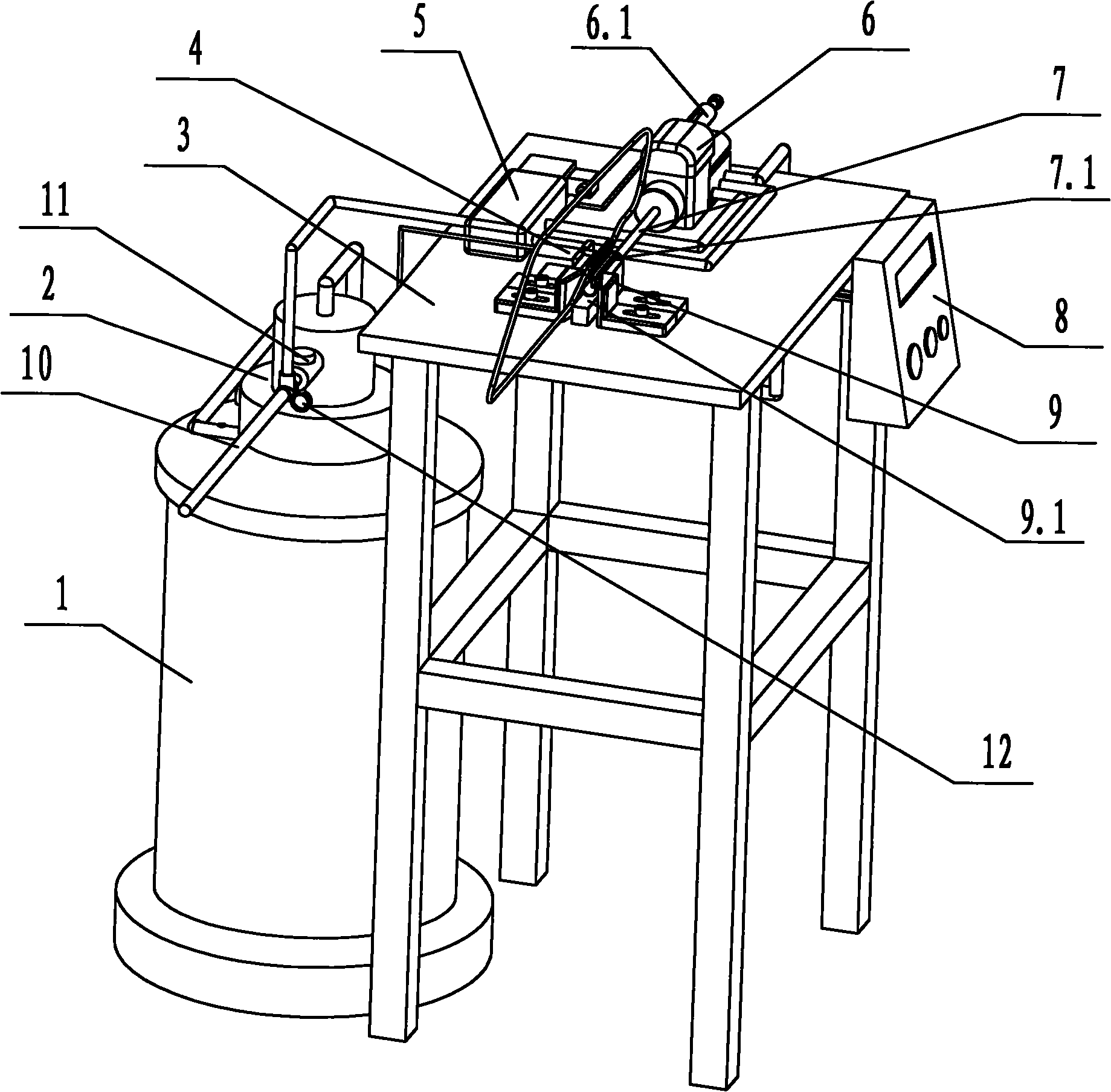

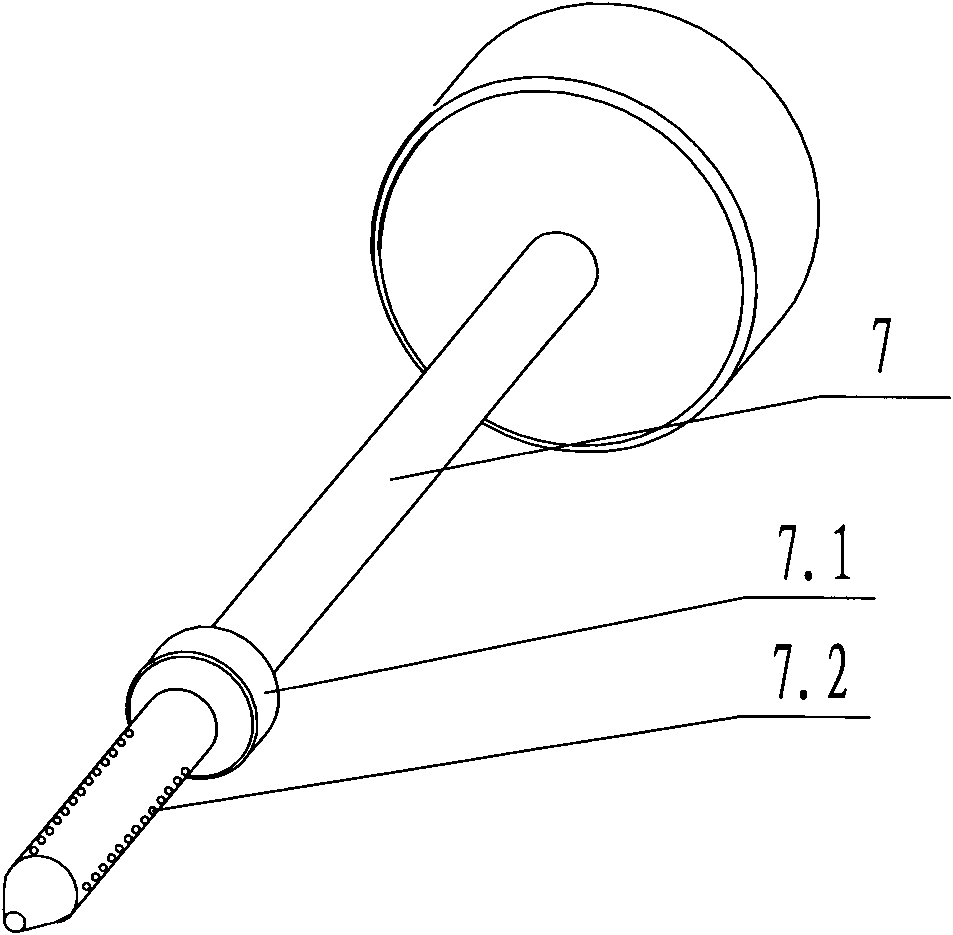

[0021] Such as figure 1 and figure 2 Shown is a grease quantitative filling device for the rotating mechanism of the sun visor of an automobile, which includes a grease bucket 1, a grease pump 2, a bracket 3, a quantitative valve 6 fixed on the bracket 3, a control switch 8 and an outlet with the quantitative valve 6 The connected injection head 7, of course, the injection head 7 is a hollow tubular structure, the inlet of the grease pump 2 communicates with the grease bucket 1, that is, the grease inlet pipeline of the grease pump 2 is arranged in the grease bucket 1, and the outlet of the grease pump 2 It communicates with the inlet of the quantitative valve 6, that is, the outlet of the grease pump 2 is connected with the inlet of the quantitative valve 6 through a pipeline, and the quantitative valve 6 is connected with the control switch 8. Of course, the control switch 8 is provided with a commercially available general-purpose circuit plate.

[0022] The support 3 is...

Embodiment 2

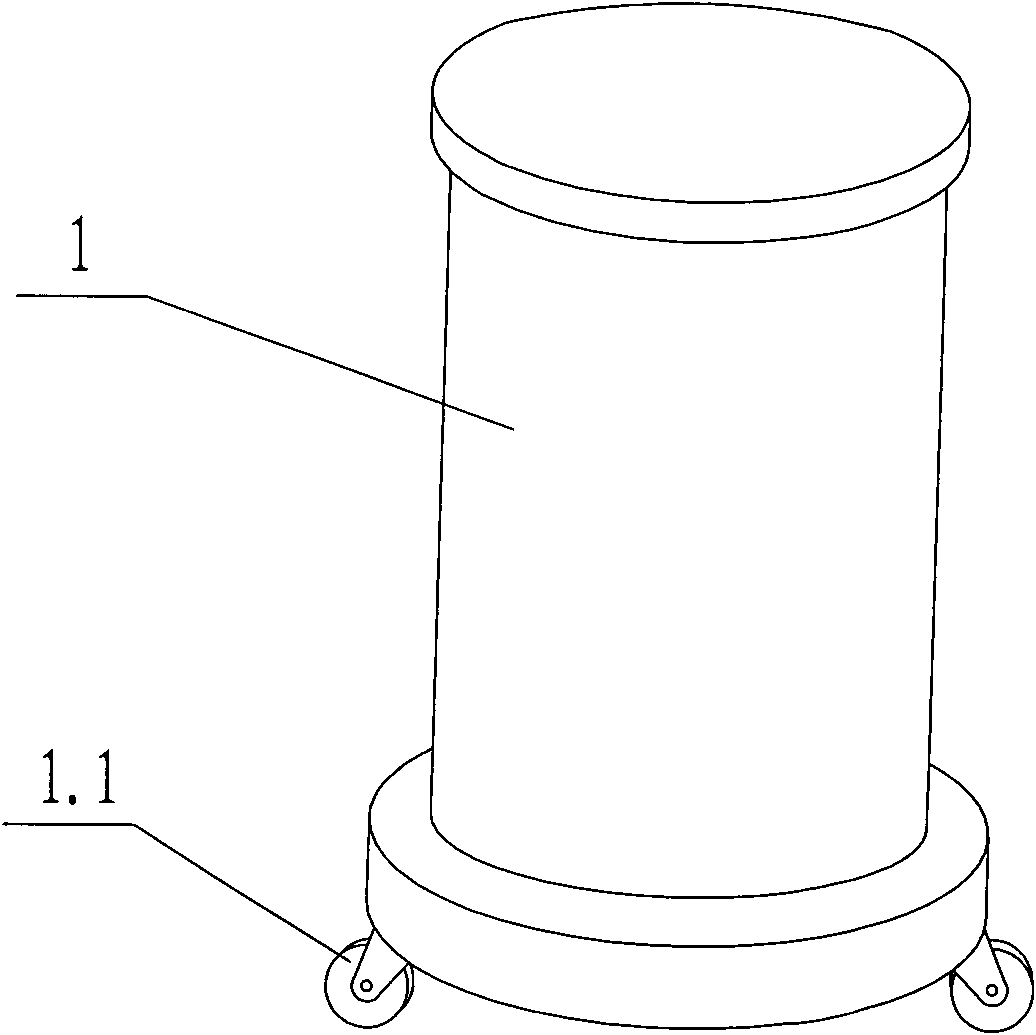

[0032] Such as image 3 As shown, the bottom of the grease barrel 1 is provided with universal wheels 1.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com