Grating lever-structured contact-pin displacement sensor and measuring method thereof

A displacement sensor and sensor technology, applied in the field of measuring instruments, can solve the problems that the instrument is difficult to measure accurately with high resolution, low signal sensitivity, and large linear error, and achieve the effects of no time drift, accurate signal output, and small linear error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

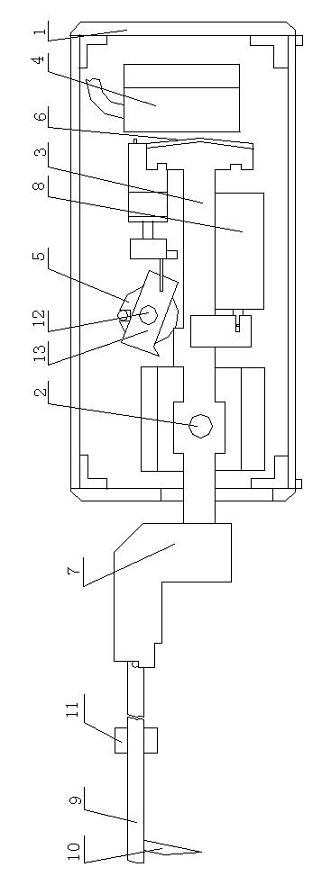

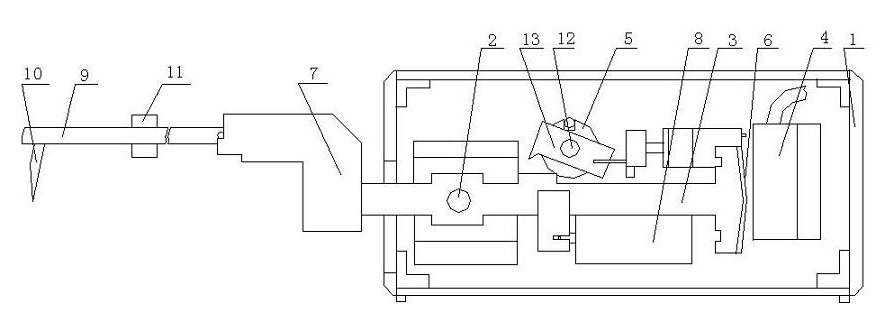

[0019] A grating type lever structure stylus displacement sensor, which consists of: a sensor base 1, the sensor base is equipped with a rotary shaft 2, a sensor lever 3, a grating reading head 4 and a pen lifting mechanism 5, the front end of the sensor lever Connect the stylus holder 7, the grating scale 6 is pasted on the arc surface of the tail of the sensor lever, the rear end of the sensor lever is connected to the damper 8 through the connecting piece, and the stylus holder is connected to the stylus 10 through the measuring rod 9 , the measuring rod is equipped with force measuring adjustment weight 11. The radius of the arc surface is equal to the distance between a point on the centerline of the arc surface of the sensor lever and the center of rotation of the rotary shaft.

[0020] As for the grating type lever structure stylus displacement sensor, the pen lifting mechanism includes a motor, and the motor is connected to a rotating shaft 12 , and the rotating shaft ...

Embodiment 2

[0024] A method of measuring using the above-mentioned sensor. When the displacement of the stylus changes, a relative displacement occurs between the grating scale of the grating system and the grating reading head, thereby converting the displacement of the stylus into an electrical signal sent by the grating reading head ;An automatic switch or a manual switch is installed on the sensor panel, and the electric signal sent by the grating system determines the control signal of the pen-lifting action; the motor rotates under the control of the pen-lifting signal, driving the pen-lifting frame to rotate around the shaft; when the switch is placed in the manual state , the sensor does not lift the pen during the measurement return process, and does not execute the pen-up and pen-down commands issued by the computer; when the switch is placed in the automatic state, the sensor can complete the pen-up and pen-down actions under the control of the computer. When the command is retu...

Embodiment 3

[0026] The grating-type lever structure stylus displacement sensor described in embodiment 1 or 2, the grating-type lever structure stylus displacement sensor, consists of a stylus, a measuring rod, a measuring rod frame, a sensor lever, a rotary shaft, a grating ruler, a reading head, and a lifter. It is composed of a pen mechanism and a damper, and a grating system composed of a grating ruler and a reading head is used as a signal conversion element.

[0027] The sensor stylus is fixed on the front end of the measuring rod, and the rear end of the measuring rod is rigidly connected to the front end of the sensor lever through the measuring rod frame; The reading window of the sensor maintains a constant distance from the metal grating ruler pasted on the arc surface of the sensor lever; The displacement is proportional to the displacement of the stylus, so that the displacement of the stylus is converted into an electrical signal from the grating reading head.

[0028] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com