Split-type triangular dynamic truck scale

A triangular and truck scale technology, applied in the field of weight balance, to achieve the effects of smooth unloading process, good buffering and vibration absorption, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

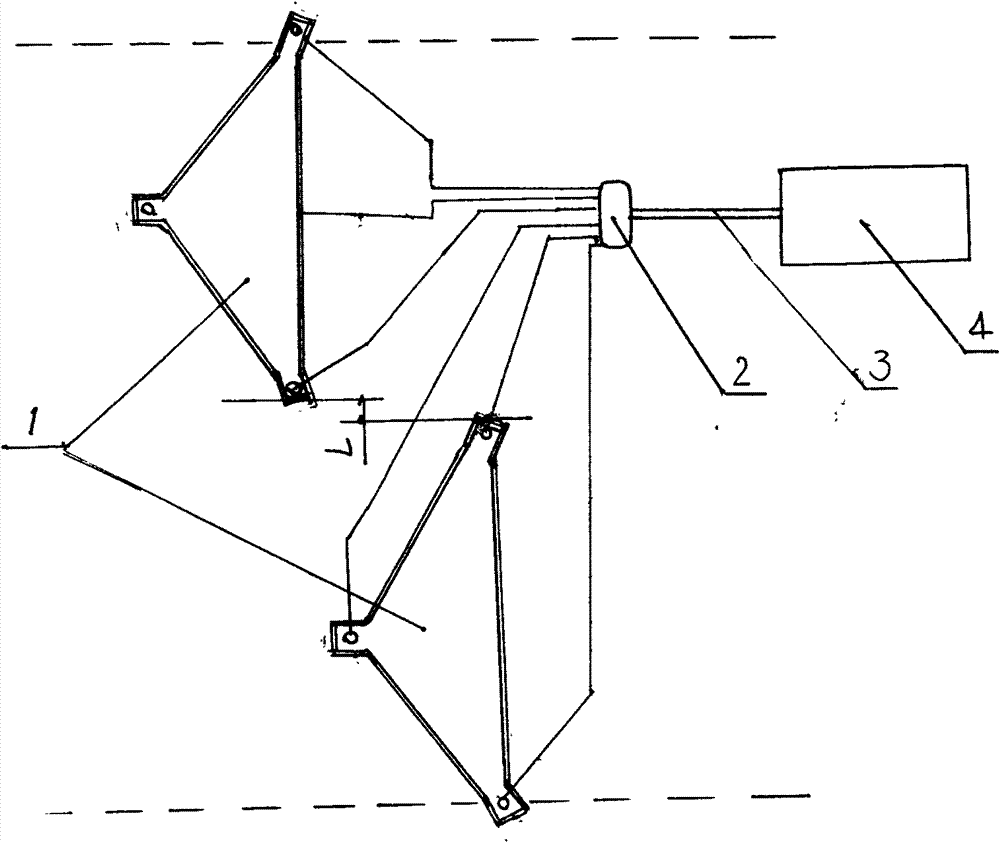

[0022] Such as figure 1 As shown, the structure of the two-body triangular dynamic truck scale is composed of two small weighing platforms 1 and a data acquisition processor 4; The plane shape is an isosceles triangle with a base length of 1590mm and a height of 640mm. When driving, go up the weighing platform from the top corner of the triangular small weighing platform 1 and get off the weighing platform from the bottom edge. The distance between two small weighing platforms 1 in the direction of the vertical lane L<100mm. The sensor signal lines of the two small weighing platforms 1 are connected to the data acquisition processor 4 through the junction box 2 and the main cable 3 .

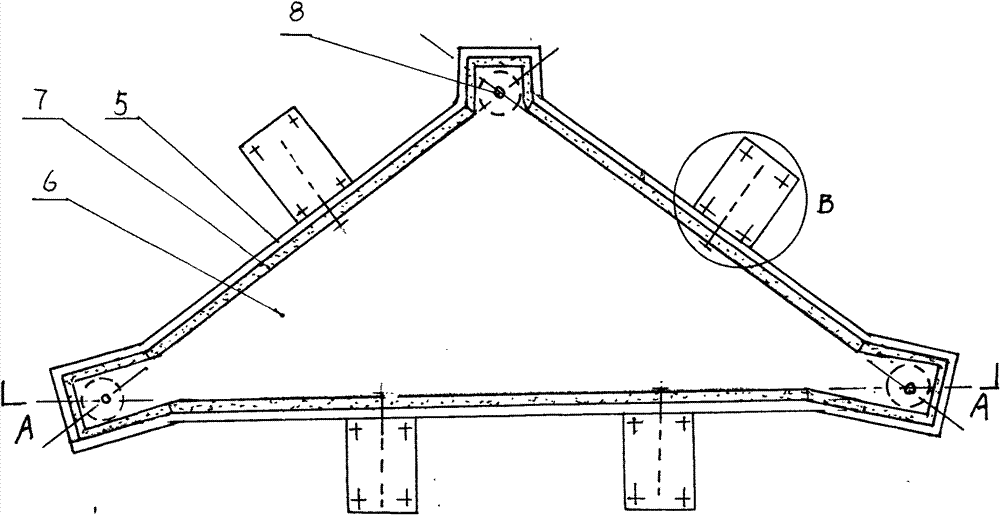

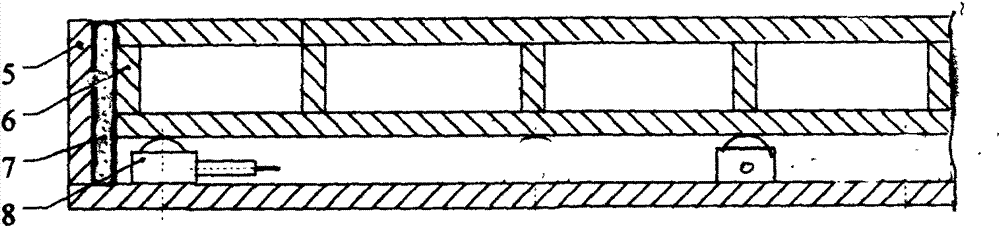

[0023] The structure of small weighing platform 1 is as figure 2 , image 3 and Figure 4 shown. It is provided with a triangular carrier 6 in the triangular frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com