Flowing cell with high flow

A flow cell, large flow technology, applied in the field of preparation of liquid chromatography detectors, can solve the problems of inability to use a large number of samples for preparation or small-scale products, insufficient flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

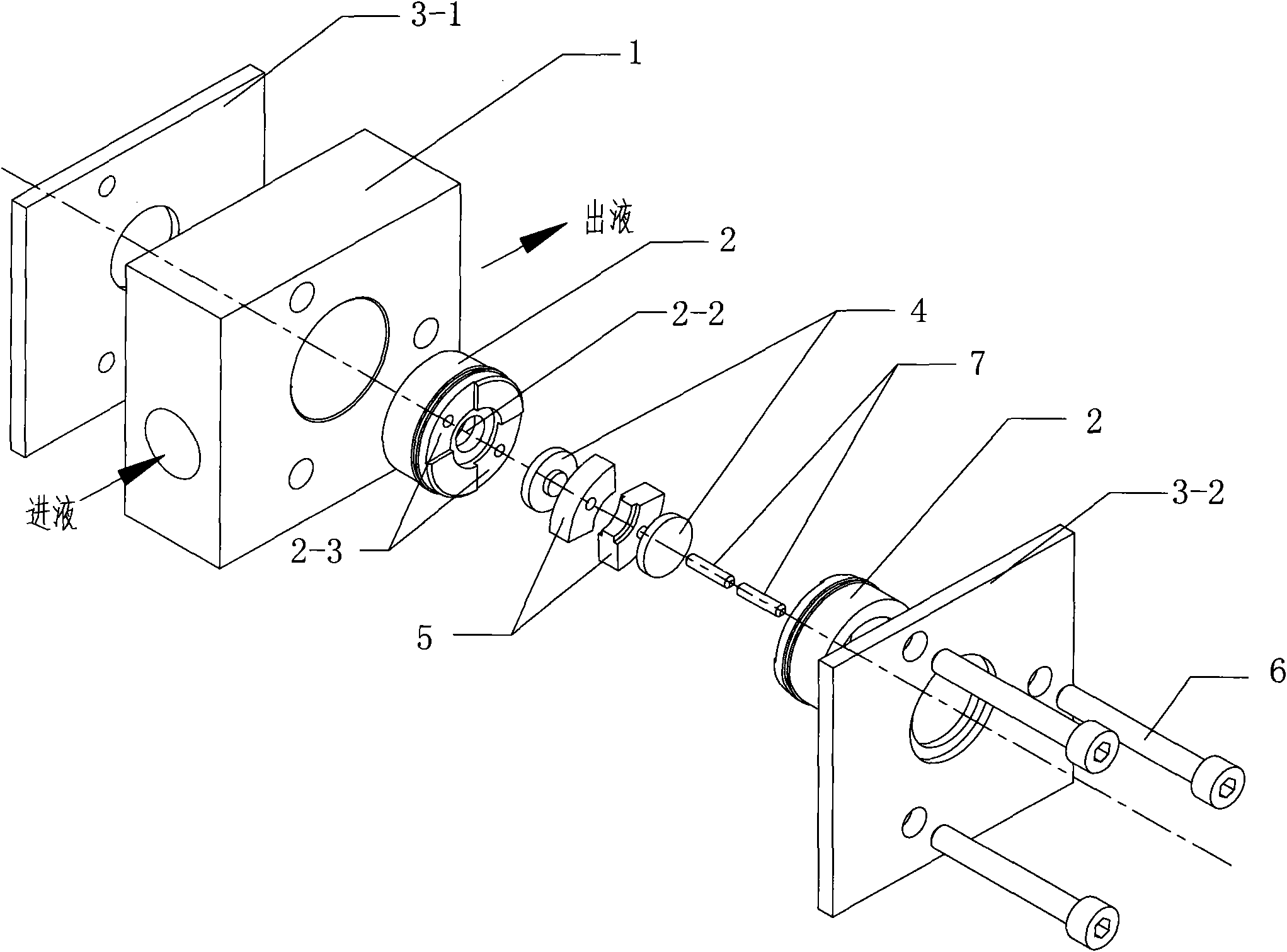

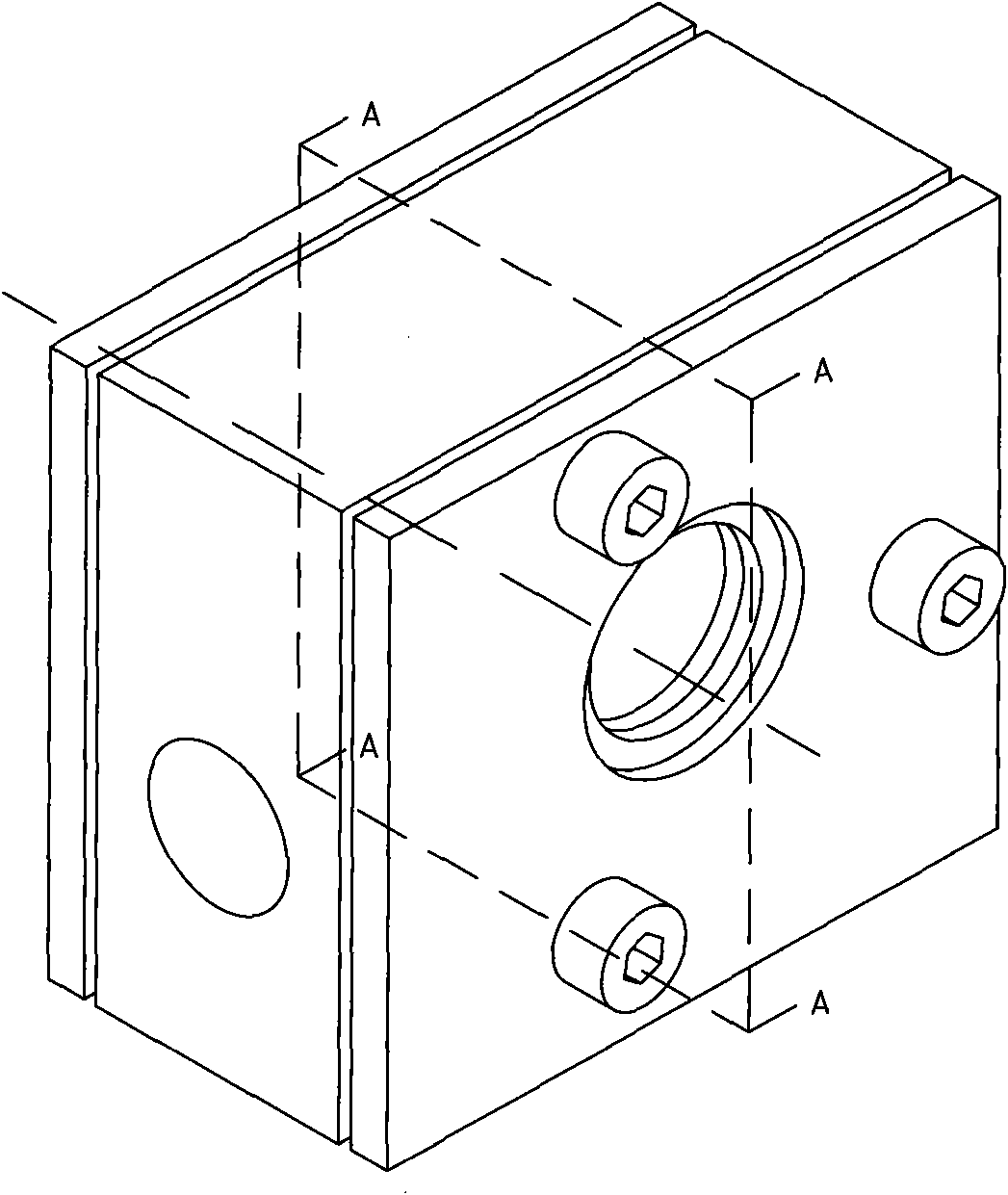

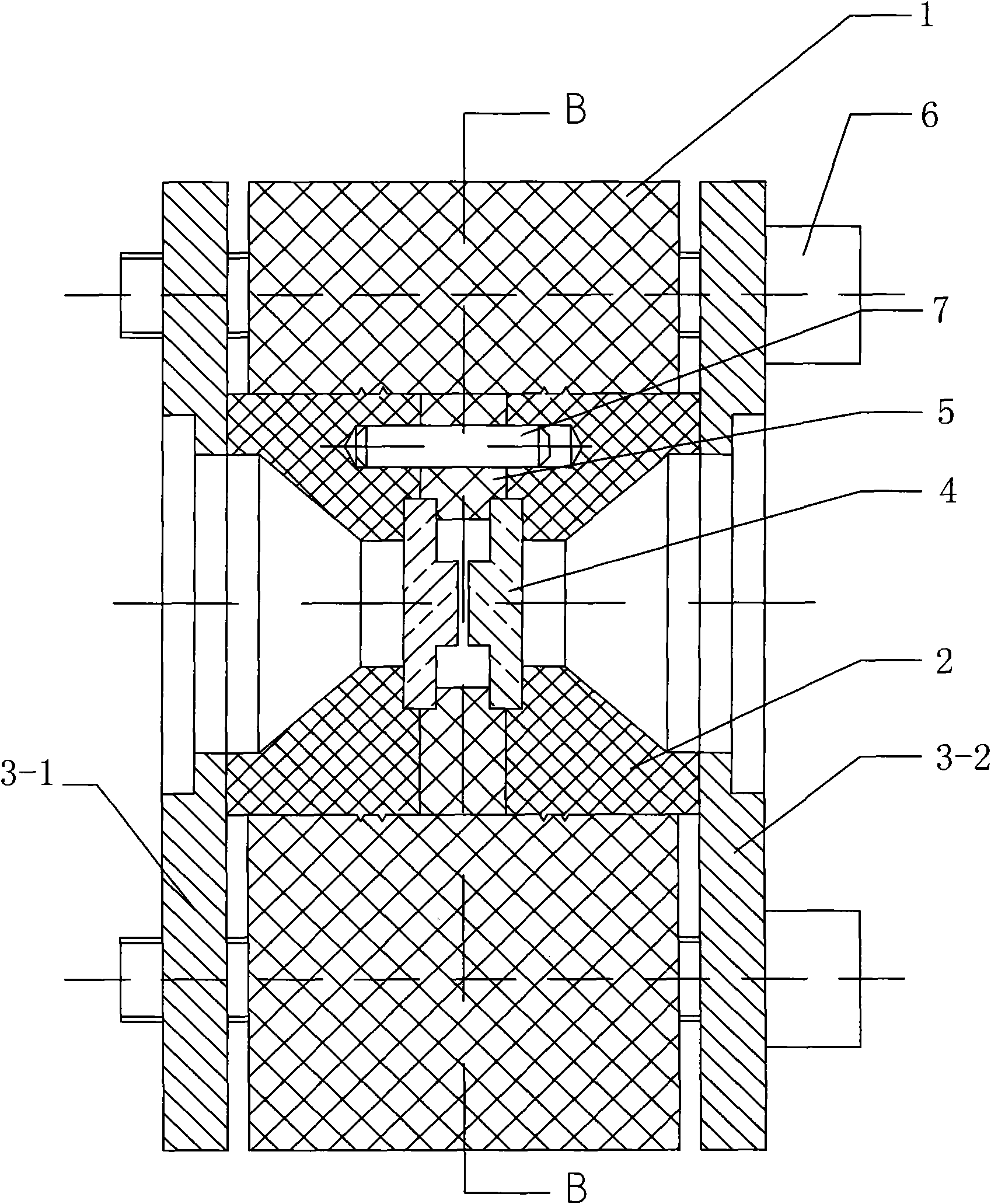

[0022] Such as Figure 1~5 The shown large flow flow cell is provided with a liquid inlet and outlet valve 1 with a flow diameter of 4mm, and the inlet and outlet valve 1 is embedded with two glands 2, at the same position opposite to each other of the two glands 2 There are two inner recessed platforms 2-3 respectively, and two quartz glass plates 4 and two clamping blocks 5 are arranged between the two glands 2, and the clamping blocks 5 are arranged inside the two glands 2. Between the bumps 2-3, a space for flowing liquid is formed between the two glands 2 after they are assembled at the same time, and the clamping block 5 is fixed on the gland 2 by a cylindrical pin 7, and the thickness of the clamping block 5 is 1 / 3 to 1 / 2 of the gap, the bottom of the clamping block 5 is in contact with the edge of the quartz glass plate 4, and the two quartz gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com