Method and system for judging mask defects

A mask and defect technology, which is applied in the field of mask defect judgment method and judgment system, can solve the problem that it is difficult to fit the mask, and achieve the effect of reducing the probability of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention quickly judges whether the mask has a defect and the location of the defect by analyzing the defect position on the wafer, so as to prevent the mask from affecting subsequent wafers and reduce the probability of defective products of the wafer; through the mask defect judgment The system can realize the function of judging the defect of the mask plate online, judge the defect mask plate in time, accurately judge the effect, and improve the judgment efficiency.

[0029] In order to make the above objects, features and advantages of the present invention more obvious and easy to understand, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

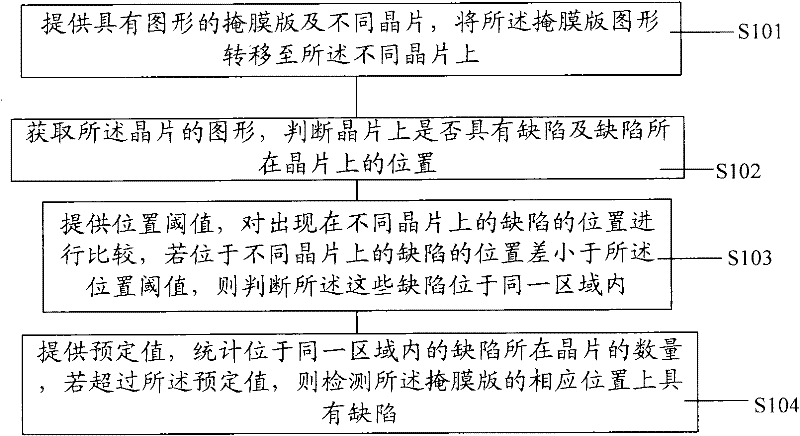

[0030] figure 1 It is a schematic flow chart of a method for judging repetitive defects according to an embodiment of the present invention, including:

[0031] Execute step S101, provide a mask plate with a pattern and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com