A heel connecting device for the production of rubber-faced plastic shoes

A connecting device and heel technology, applied in applications, household appliances, household components, etc., can solve problems such as errors and reduce production efficiency, and achieve the effects of safe and convenient use, increased production efficiency, and scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

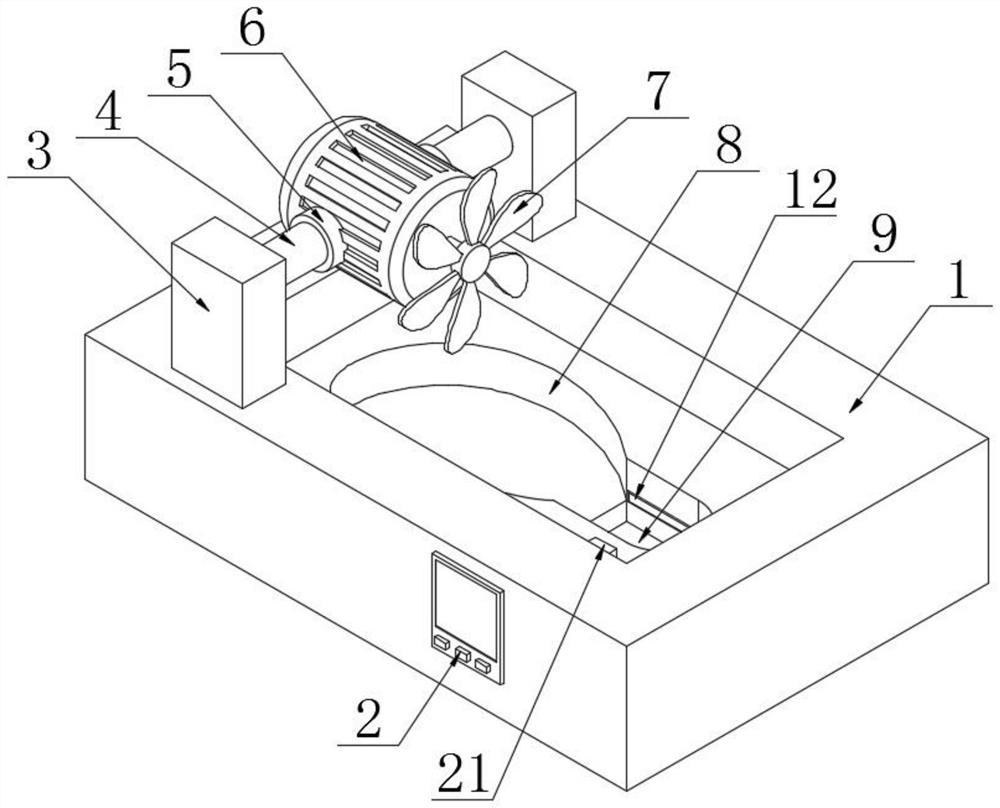

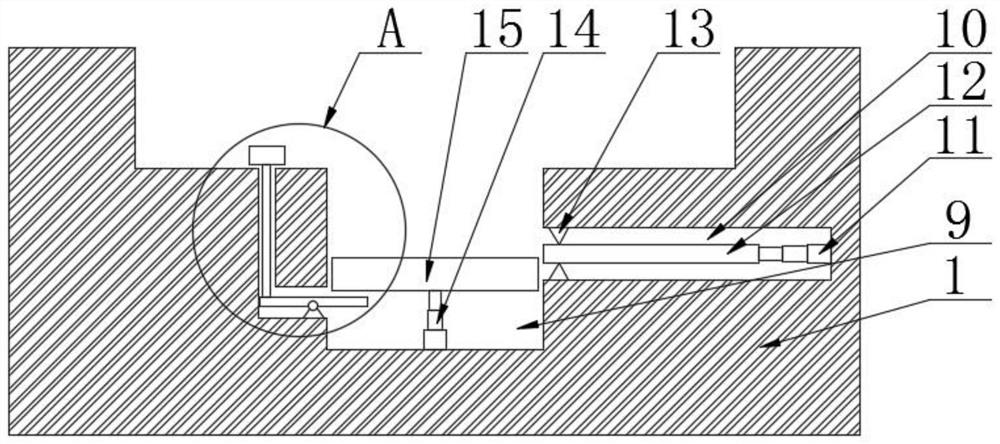

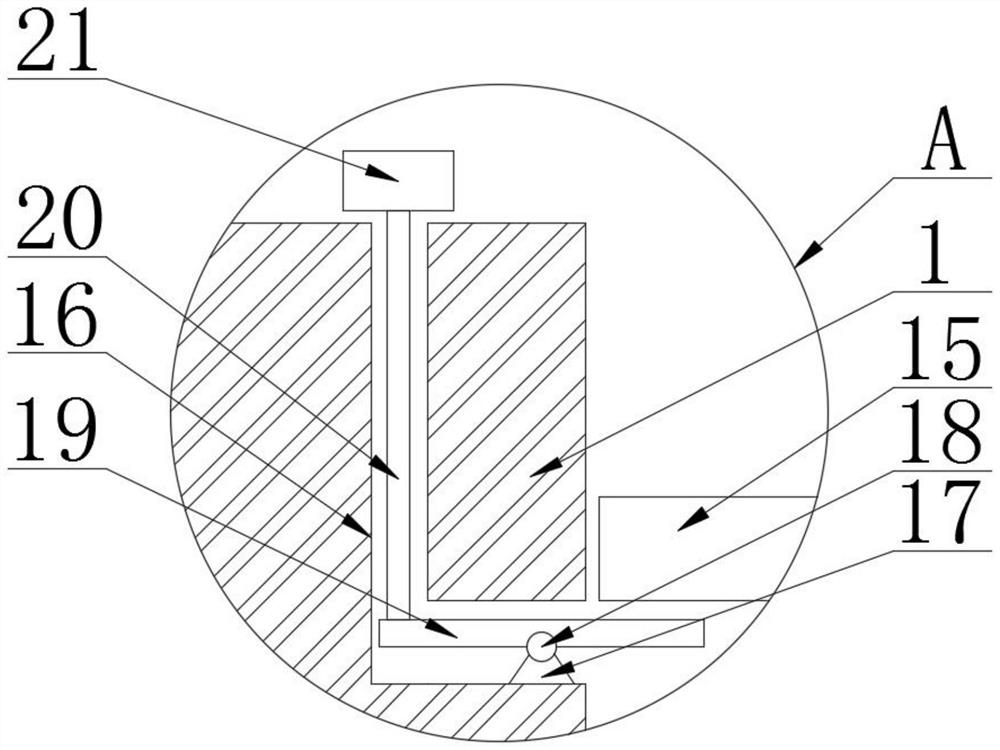

[0021] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, including a box body 1, a control button 2, a mounting frame 3, a connecting rod 4, a mounting bearing 5, a motor 6, a fan 7, a sole groove 8, a heel groove 9, and a mounting groove 10 , electric push rod 11, heating plate 12, spatula 13, telescopic rod 14, partition 15, mounting hole 16, mounting seat 17, fixed bearing 18, rocker 19, adjusting rod 20 and adjusting button 21, the box body 1 One side is embedded with a control button 2, and the two sides of the top of the box body 1 are correspondingly fixedly installed with a mounting frame 3, and one side of the mounting frame 3 is fixedly mounted with a connecting rod 4, in order to ensure the stability of the connection between the mounting frame 3 and the connecting rod 4 The installation frame 3 and the connecting rod 4 are connected by welding, the motor 6 is installed on one side of the connecting rod 4 through the install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com