Opening terminal connector

A terminal connector, auxiliary terminal technology, applied in the direction of connection, conductive connection, contact parts, etc., can solve the problems of complex and time-consuming, competitive impact, unfavorable welding operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

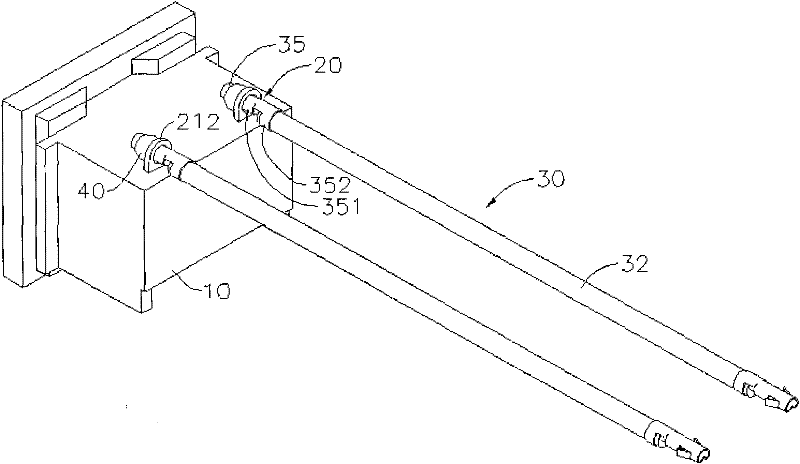

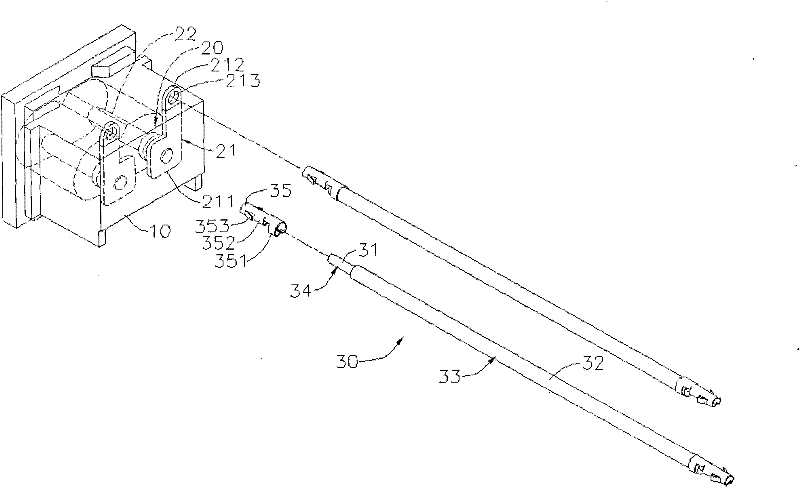

[0025] The open-hole terminal connector includes two auxiliary terminals (20), and each auxiliary terminal (20) has an engaging plate (21) and a conductive plug (22).

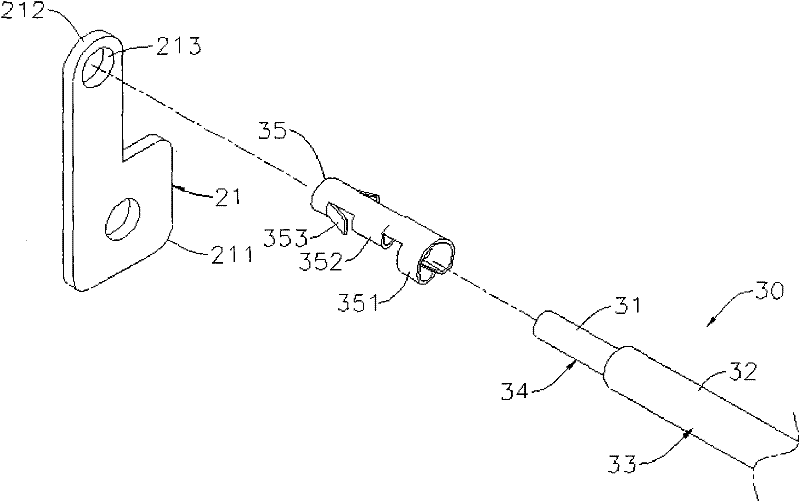

[0026] In the open-hole terminal connector disclosed by the present invention, the engaging plate (21) has a joint portion (211), an engaging portion (212) and an engaging hole (213). The bonding part (211) is bonded to the insulating shell (10), and it is bonded to the insulating shell (10) in a manner of embedding or riveting. When the bonding part ( 211 ) is combined with the insulating casing ( 10 ) by embedding, it can be combined with the embedding mold injection molding method to form a cladding form.

[0027] Such as figure 2 As shown, in the open-hole terminal connector disclosed by the present invention, the engaging portion ( 212 ) is exposed outside the insulating housing ( 10 ). The engaging hole (213) is formed on the engaging part (212). Also, the conductive pin (22) is arranged on the joint ...

specific Embodiment 2

[0030] Such as Figure 4 As shown, another embodiment of the present invention combines the joint portion (211) of the clamping plate (21) with the insulating housing (10) by riveting, and first positions the joint portion (211) on the insulating housing (10) ) outside, and then riveting the joint (211) on the insulating housing (10).

[0031] Because the present invention can conveniently insert and engage the connecting wire (30) on the auxiliary terminal (20) through the above-mentioned structure, and because the engaging portion (353) is formed in a uniform standard, therefore The shape after the engagement is consistent, which is beneficial to a large number of welding operations, and the connection between the connecting wire (30) and the auxiliary terminal (20) can be strengthened by solder (40) smoothly and quickly, thereby reducing the complexity of the operation and greatly Save operating time, improve yield and save manufacturing costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com