Adaptive control of arc welding parameters

A technology of welding parameters and parameters, applied in the direction of arc welding equipment, applications, welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

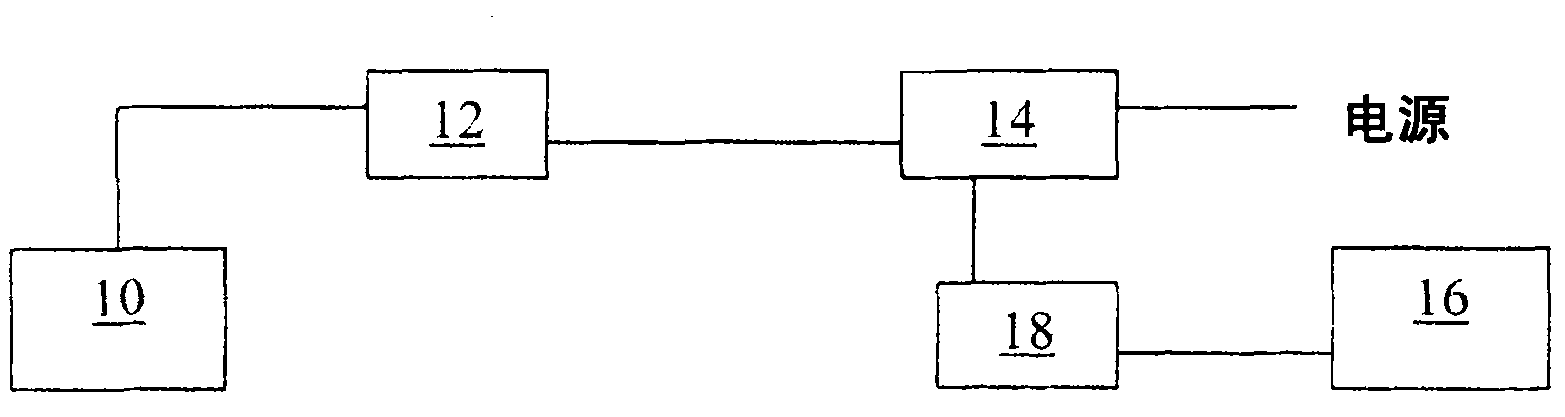

[0016] figure 2 It is a schematic explanatory diagram of the device configuration of the present invention. The equipment configuration includes a laser scanner 10, a laser scanner controller 12, a power adapter 14, a computer 16, and a switch 18 (if necessary). The switch is used to import information into and out of the computer 16.

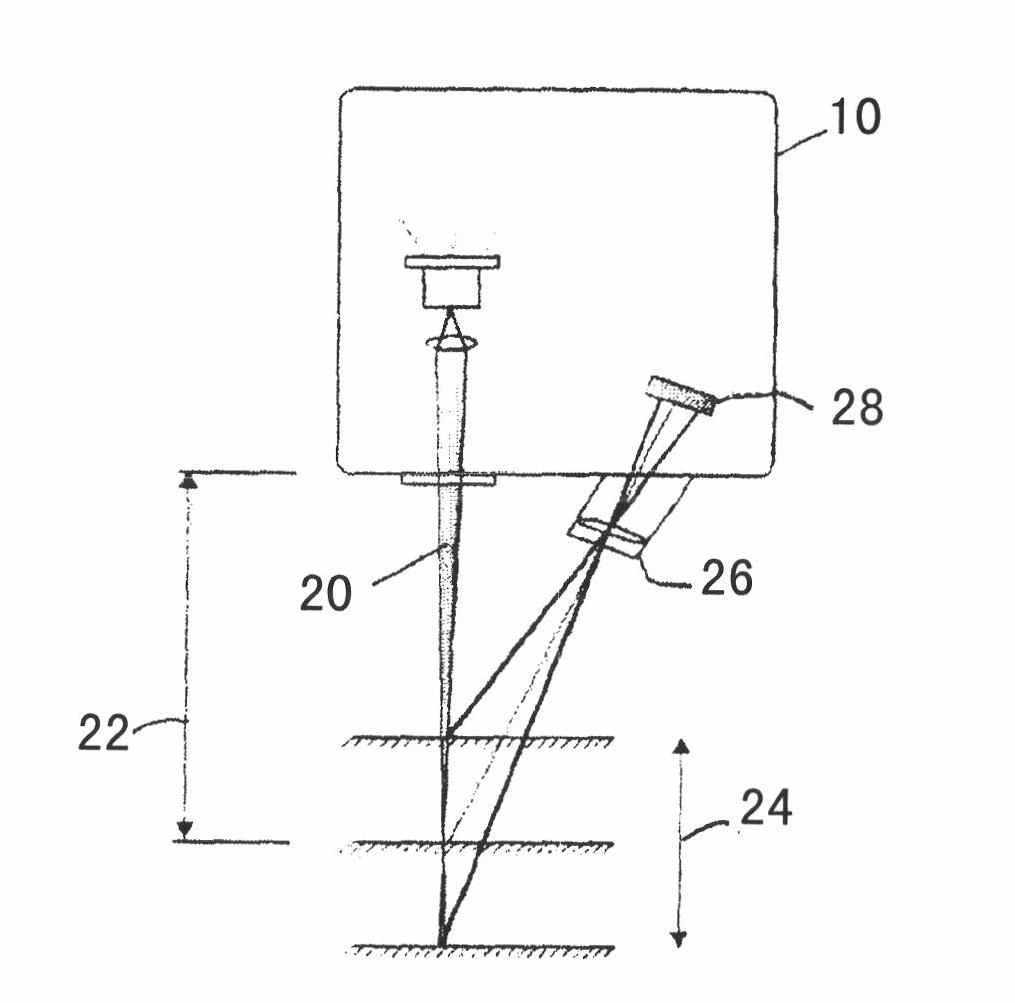

[0017] Such as image 3 As shown, the laser scanner 10 projects a laser line 20 in a fixed operating window including a reference distance 22 and a measurement range 24. The laser generates a reflection position of anything that the laser line 20 "sees" in the operating window. The lens 26 focuses the laser reflection on the CCD 28. For use in the welding operation, the reflected signal received by the CCD 28 is recorded by the computer 16. With the help of triangulation, the precise distance of the object from the laser can be measured at any point along the laser line. The recorded laser reflection measurements provide a 360 degree actual jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com